Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cutting and Creasing Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

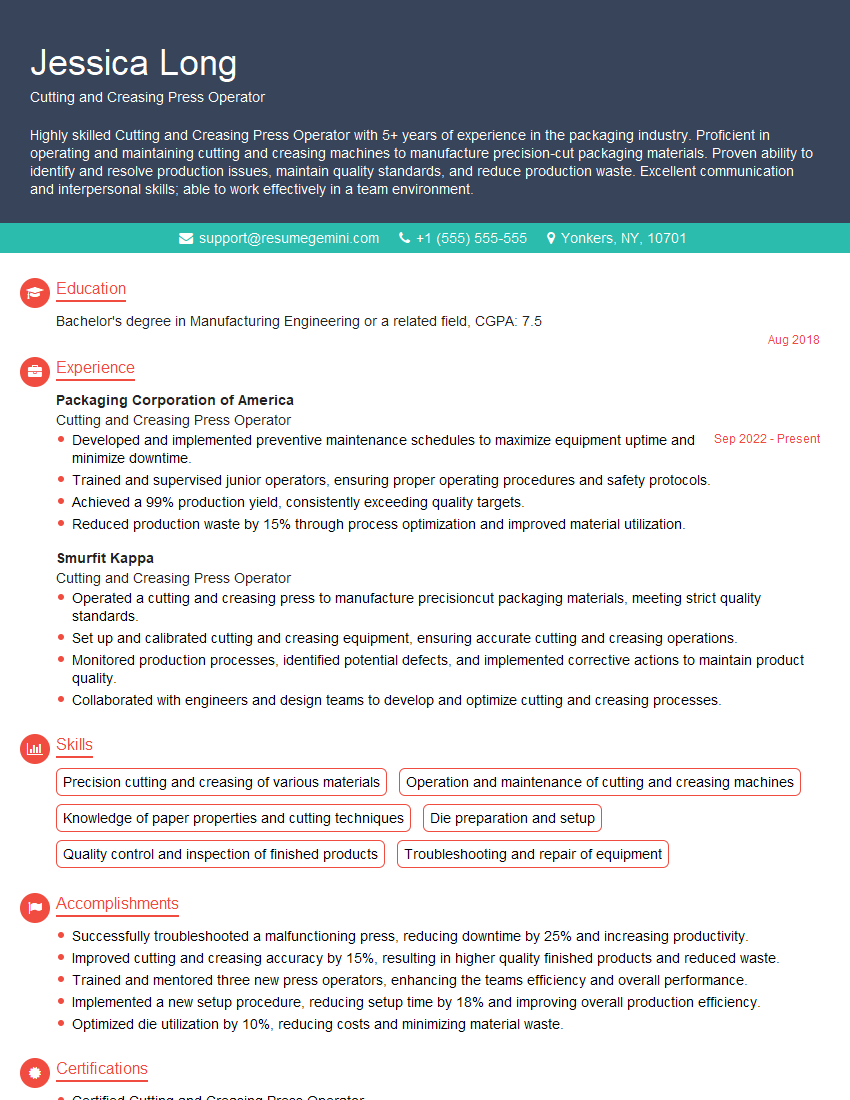

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutting and Creasing Press Operator

1. Explain the process of setting up a cutting and creasing press.

- Inspect the materials to ensure they are suitable for the job.

- Mount the die to the press bed.

- Set the impression pressure and dwell time.

- Run a few test cuts to check the quality of the cut.

2. What are the different types of cutting and creasing dies?

Solid dies

- Used for cutting and creasing in one operation.

- Made from steel or plastic.

Combination dies

- Used for cutting and creasing in separate operations.

- Made from steel or plastic.

Rotary dies

- Used for cutting and creasing continuous webs of material.

- Made from steel or plastic.

3. What are the safety precautions that must be followed when operating a cutting and creasing press?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep hands and other body parts away from the cutting and creasing area.

- Do not operate the press if it is not properly guarded.

- Be aware of the location of the emergency stop button.

4. What are the common problems that can occur when operating a cutting and creasing press, and how can they be solved?

Die wear

- Can cause the cut or crease to be ragged or uneven.

- Can be solved by replacing the die.

Misaligned dies

- Can cause the cut or crease to be off-center or skewed.

- Can be solved by adjusting the die settings.

Dull cutting blade

- Can cause the cut to be ragged or uneven.

- Can be solved by sharpening the blade.

Improper impression pressure

- Can cause the cut or crease to be too deep or too shallow.

- Can be solved by adjusting the impression pressure.

Improper dwell time

- Can cause the cut or crease to be incomplete.

- Can be solved by adjusting the dwell time.

5. What are the maintenance procedures that must be performed on a cutting and creasing press?

- Weekly: Inspect the dies for wear and damage.

- Monthly: Lubricate the press according to the manufacturer’s instructions.

- Quarterly: Perform a thorough cleaning of the press.

- Annually: Have the press inspected by a qualified technician.

6. What is your experience with troubleshooting cutting and creasing press problems?

- I have experience troubleshooting a variety of cutting and creasing press problems, including:

- Die wear

- Misaligned dies

- Dull cutting blade

- Improper impression pressure

- Improper dwell time

7. What is your experience with setting up and operating different types of cutting and creasing presses?

- I have experience setting up and operating a variety of cutting and creasing presses, including:

- Platen presses

- Cylinder presses

- Rotary presses

8. What is your experience with working with different types of materials on a cutting and creasing press?

- I have experience working with a variety of materials on a cutting and creasing press, including:

- Paper

- Cardboard

- Plastic

- Metal

9. What is your experience with quality control for cutting and creasing operations?

- I have experience with quality control for cutting and creasing operations, including:

- Inspecting materials for defects

- Setting up and operating the press to meet quality standards

- Inspecting finished products for defects

10. What are your strengths and weaknesses as a Cutting and Creasing Press Operator?

Strengths

- Attention to detail

- Strong mechanical skills

- Ability to work independently and as part of a team

Weaknesses

- I am relatively new to the industry.

- I am still learning how to operate some of the more complex presses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutting and Creasing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutting and Creasing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cutting and Creasing Press Operator plays a vital role in converting raw materials into finished products, ensuring precision and quality in the production process. They are responsible for operating machines that cut, crease, and shape various materials such as paper, cardboard, and plastic sheets.

1. Machine Operation

The operator must be proficient in setting up, operating, and maintaining cutting and creasing presses. This includes adjusting and calibrating the machines, selecting and installing the appropriate dies, and performing regular maintenance to ensure optimal performance.

- Set up and operate cutting and creasing presses according to job specifications.

- Select and install appropriate cutting and creasing dies.

- Monitor machine operation and make adjustments as needed to maintain quality and efficiency.

2. Material Handling

Efficient handling of materials is crucial for the operator. They are responsible for loading and unloading sheets onto the press, as well as inspecting and sorting the finished products. Careful handling techniques help prevent damage and ensure the quality of the final products.

- Load and unload materials from the press.

- Inspect finished products for quality and accuracy.

- Sort and stack finished products.

3. Quality Control

The operator is tasked with ensuring the quality of the finished products. They perform regular inspections throughout the production process to identify and correct any defects or inconsistencies. Maintaining high quality standards is essential for customer satisfaction and reputation.

- Inspect materials before and after cutting and creasing.

- Identify and correct defects or inconsistencies.

- Maintain quality control records.

4. Safety Compliance

A safe work environment is paramount. The operator must adhere to established safety protocols and wear appropriate safety gear to minimize risks and ensure the well-being of themselves and others.

- Follow established safety protocols.

- Wear appropriate safety gear.

- Report any safety concerns or incidents.

Interview Tips

To maximize your chances of success in an interview for a Cutting and Creasing Press Operator position, consider the following preparation tips and hacks:

1. Research the Company and Role

Demonstrate your interest and enthusiasm by thoroughly researching the company and the specific role you’re applying for. Familiarize yourself with the company’s products, services, and culture, and tailor your answers accordingly.

- Visit the company’s website and social media profiles.

- Read industry news and articles related to the company.

- Practice answering common interview questions and tailoring them to the job description.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact and value.

- Review the job description and identify the key skills and responsibilities.

- Prepare specific examples that showcase your proficiency in these areas.

- Use numbers and metrics to illustrate your contributions and results.

3. Practice Active Listening and Ask Thoughtful Questions

Throughout the interview, pay close attention to the interviewer’s questions and respond thoughtfully. Ask clarifying questions when needed and engage in meaningful discussions to demonstrate your interest and understanding.

- Listen attentively to the interviewer’s questions and take time to compose your answers.

- Ask thoughtful questions that demonstrate your engagement and curiosity.

- Prepare a few questions in advance to show your interest in the role and the company.

4. Be Enthusiastic and Confident

Maintain a positive and enthusiastic demeanor throughout the interview. Confidence in your abilities and skills will make a strong impression on the interviewer.

- Dress professionally and arrive on time for the interview.

- Maintain good eye contact and a friendly smile.

- Speak clearly and confidently about your qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cutting and Creasing Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!