Are you gearing up for an interview for a Cutting and Splicing Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cutting and Splicing Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

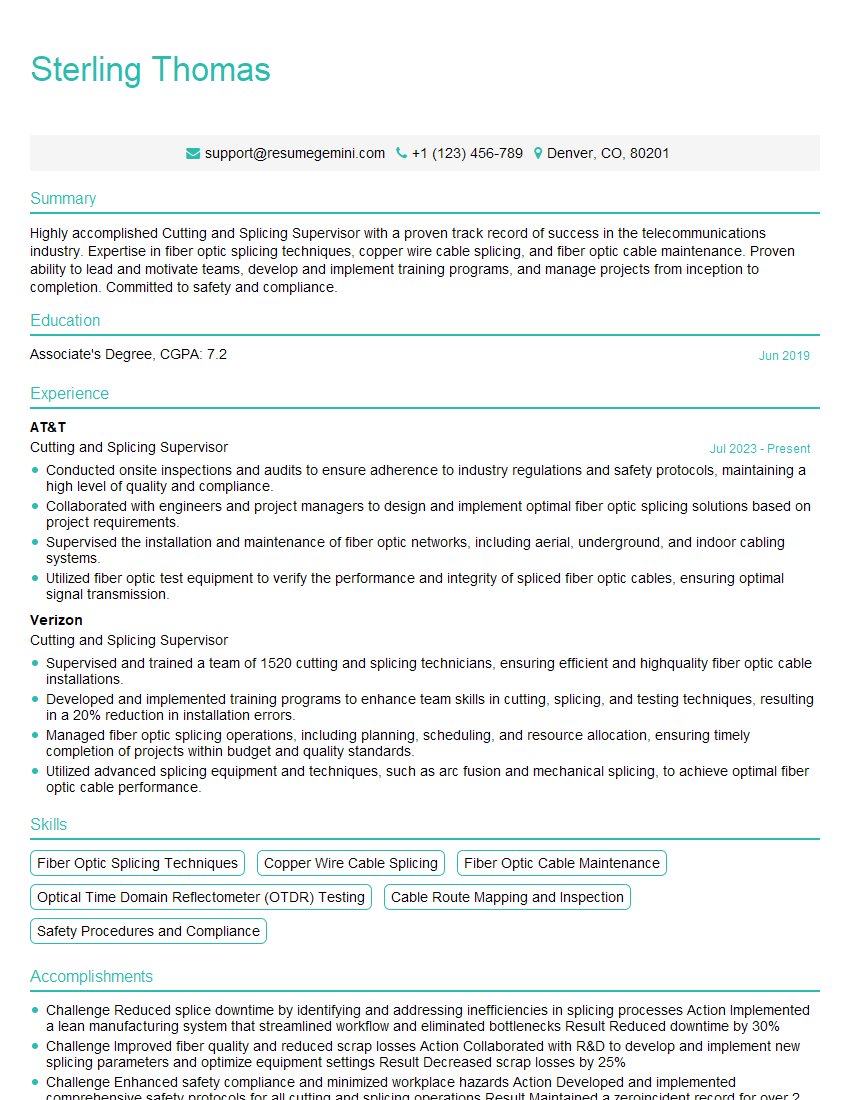

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutting and Splicing Supervisor

1. What are the different types of splicing techniques used in fiber optic splicing?

In fiber optic splicing, there are several different techniques used, each with its own advantages and disadvantages. The most common types of splicing techniques include:

- Fusion splicing: Fusion splicing is a permanent method of splicing that joins two fibers together by melting them and fusing them together. This results in a strong, low-loss connection that is nearly invisible to the naked eye.

- Mechanical splicing: Mechanical splicing is a non-permanent method of splicing that uses a mechanical device to hold two fibers together. This method is quick and easy to perform, but it is not as strong or reliable as fusion splicing.

- Ribbon splicing: Ribbon splicing is a method of splicing that is used to join multiple fibers together at once. This method is often used in high-density applications where space is limited.

2. What are the different types of fiber optic cables?

Single-mode fiber

- Used for long-distance transmission

- Only one mode of light can travel through the fiber

- Has a smaller core size than multi-mode fiber

Multi-mode fiber

- Used for short-distance transmission

- Multiple modes of light can travel through the fiber

- Has a larger core size than single-mode fiber

3. What are the different types of fiber optic connectors?

- SC connector: SC connectors are a type of fiber optic connector that is commonly used in telecommunications applications. They are a push-pull type connector that is easy to use and has a low insertion loss.

- LC connector: LC connectors are a type of fiber optic connector that is commonly used in data center applications. They are a latching type connector that is compact and has a low insertion loss.

- MTP connector: MTP connectors are a type of fiber optic connector that is commonly used in high-density applications. They are a multi-fiber connector that can accommodate up to 24 fibers in a single connector.

4. What are the different types of fiber optic test equipment?

- Optical power meter: An optical power meter is a device that is used to measure the power of an optical signal.

- Optical loss test set: An optical loss test set is a device that is used to measure the loss of an optical signal over a fiber optic link.

- Optical time domain reflectometer (OTDR): An OTDR is a device that is used to measure the distance to a fault in a fiber optic link.

5. What are the safety precautions that should be taken when working with fiber optics?

- Wear eye protection: Fiber optic cables can emit harmful levels of light that can damage your eyes.

- Do not look directly into a fiber optic cable: The light emitted from a fiber optic cable can be blinding.

- Do not touch the ends of fiber optic cables: The ends of fiber optic cables are sharp and can cut your skin.

6. What are the different types of fiber optic splice closures?

- Heat-shrink splice closure: Heat-shrink splice closures are a type of splice closure that is made of a heat-shrinkable material. When heat is applied to the closure, it shrinks and forms a tight seal around the splices.

- Mechanical splice closure: Mechanical splice closures are a type of splice closure that is made of a rugged material that is designed to protect the splices from the elements.

- Butt splice closure: Butt splice closures are a type of splice closure that is used to connect two fibers together end-to-end.

7. What are the different types of fiber optic distribution frames?

- Wall-mount distribution frame: Wall-mount distribution frames are a type of distribution frame that is mounted on a wall.

- Rack-mount distribution frame: Rack-mount distribution frames are a type of distribution frame that is mounted in a rack.

- Floor-mount distribution frame: Floor-mount distribution frames are a type of distribution frame that is mounted on the floor.

8. What are the different types of fiber optic patch cords?

- Simplex patch cord: Simplex patch cords are a type of patch cord that has one fiber.

- Duplex patch cord: Duplex patch cords are a type of patch cord that has two fibers.

- Multi-fiber patch cord: Multi-fiber patch cords are a type of patch cord that has more than two fibers.

9. What are the different types of fiber optic adapters?

- SC adapter: SC adapters are a type of adapter that is used to connect SC connectors.

- LC adapter: LC adapters are a type of adapter that is used to connect LC connectors.

- MTP adapter: MTP adapters are a type of adapter that is used to connect MTP connectors.

10. What are the different types of fiber optic transceivers?

- SFP transceiver: SFP transceivers are a type of transceiver that is used in small form-factor pluggable (SFP) ports.

- GBIC transceiver: GBIC transceivers are a type of transceiver that is used in gigabit interface converter (GBIC) ports.

- XFP transceiver: XFP transceivers are a type of transceiver that is used in 10-gigabit small form-factor pluggable (XFP) ports.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutting and Splicing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutting and Splicing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cutting and Splicing Supervisors are responsible for overseeing the splicing and cutting operations within a manufacturing or production facility. They ensure that products are cut and spliced to the correct specifications and that all safety protocols are followed. Key responsibilities include:

1. Supervise Cutting and Splicing Processes

Directing and monitoring the cutting and splicing of materials, ensuring adherence to specifications, quality standards, and production schedules.

- Develop and implement cutting and splicing procedures.

- Train and supervise cutting and splicing operators.

- Monitor and evaluate cutting and splicing performance.

2. Manage Equipment and Inventory

Maintaining and calibrating cutting and splicing equipment, ensuring optimal performance and minimizing downtime.

- Procure and manage cutting and splicing supplies.

- Maintain an inventory of cutting and splicing materials.

- Monitor equipment usage and identify areas for improvement.

3. Ensure Safety and Quality

Enforcing safety protocols and regulations, promoting a safe working environment, and ensuring the quality of cut and spliced products.

- Conduct safety inspections and audits.

- Investigate accidents and incidents.

- Implement quality control measures.

- Monitor and analyze quality data.

4. Collaborate with Other Departments

Coordinating with other departments, such as engineering, production, and quality control, to ensure seamless operations and resolve issues.

- Communicate with customers to address any concerns or inquiries.

- Participate in continuous improvement initiatives.

- Provide technical support and guidance to other departments.

Interview Tips

To ace an interview for a Cutting and Splicing Supervisor position, candidates should:

1. Research the Company and Industry

Demonstrate knowledge of the company’s products, services, and industry trends. Researching the company’s website, news articles, and social media accounts can provide valuable insights.

- Tailor your resume and cover letter to highlight your experience and skills that are most relevant to the position.

- Prepare specific examples of how you have successfully managed cutting and splicing operations in the past.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience, skills, and qualifications. Practice answering questions in a clear and concise manner, using the STAR method (Situation, Task, Action, Result) whenever possible.

- Anticipate questions about your experience in supervising cutting and splicing operations.

- Prepare examples of how you have handled challenging situations, such as equipment breakdowns or quality issues.

3. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions that demonstrate your understanding of the company and the role.

- Ask about the company’s growth plans and how the cutting and splicing operations contribute to those plans.

- Inquire about the company’s commitment to safety and quality.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. Be polite and respectful to everyone you encounter, including the receptionist and other employees.

- Make sure your outfit is clean, pressed, and appropriate for a professional setting.

- Plan your route and transportation in advance to avoid any delays.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cutting and Splicing Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.