Are you gearing up for a career in Cutting Machine Fixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cutting Machine Fixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

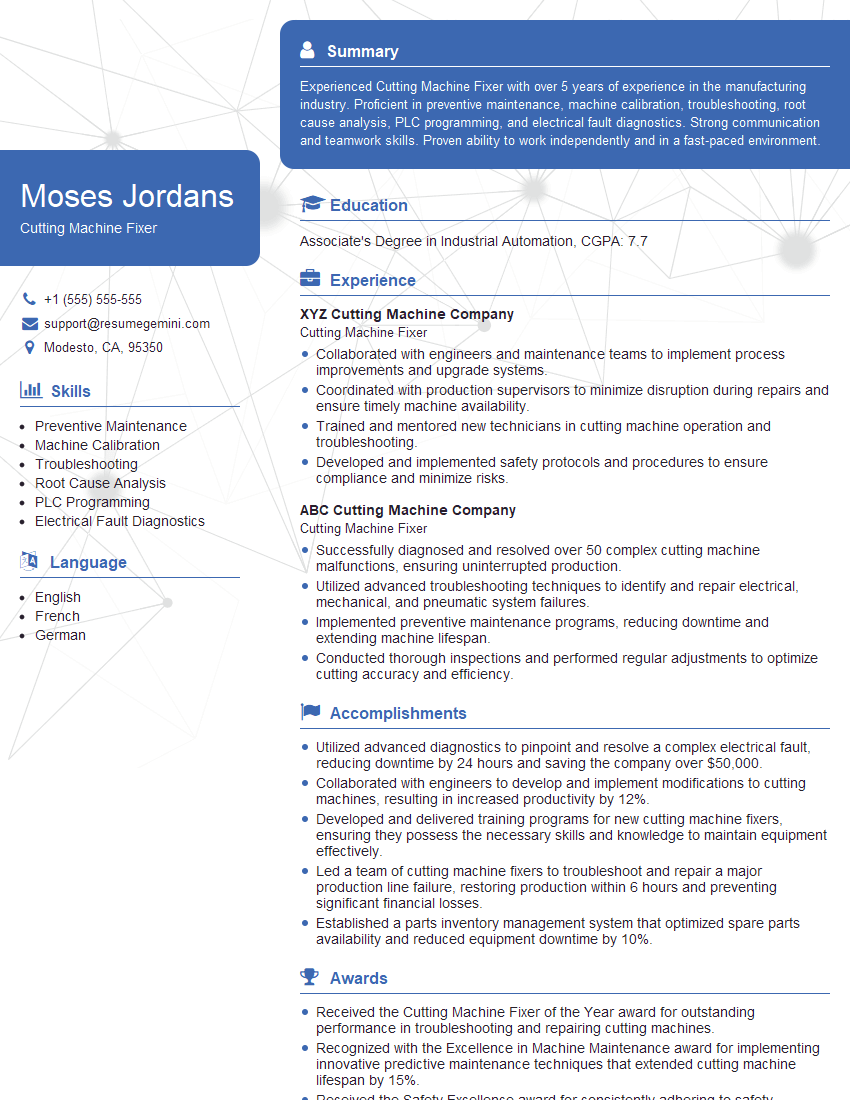

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutting Machine Fixer

1. What are the key components of a cutting machine and their functions?

- Blade: The sharp cutting element that cuts through the material.

- Bed: The surface on which the material is placed and cut.

- Drive system: The mechanism that moves the blade through the material.

- Control system: The electronic or manual interface that controls the machine’s operation.

- Safety features: Devices to prevent operator injury, such as guards and emergency stop buttons.

2. Describe the different types of cutting machines used in various industries.

CNC cutting machines

- Laser cutters: Use a high-powered laser to cut precise shapes into metal, wood, plastic, and other materials.

- Waterjet cutters: Use a high-pressure water jet mixed with abrasive particles to cut hard materials like metals and ceramics.

- Plasma cutters: Use a high-temperature plasma arc to cut conductive materials like steel and aluminum.

Manual cutting machines

- Band saws: Use a continuous band saw blade to cut through metal, wood, and plastic.

- Circular saws: Use a rotating circular blade to cut straight or curved lines in wood and metal.

- Jigsaw: Use a reciprocating blade to cut intricate shapes in wood, metal, and plastic.

3. What are the common problems encountered with cutting machines and their troubleshooting techniques?

- Blade dullness: Sharpen or replace the blade.

- Misalignment: Adjust the machine’s components to ensure proper alignment.

- Material defects: Inspect the material for flaws or impurities that may cause cutting problems.

- Electrical faults: Check electrical connections, fuses, and wiring for damage or loose connections.

- Hydraulic/pneumatic failures: Inspect hydraulic/pneumatic systems for leaks, blockages, or pressure issues.

4. How do you prioritize multiple maintenance tasks on a cutting machine and allocate resources effectively?

- Assess the urgency and impact of each task: Determine which tasks are critical for production and need immediate attention.

- Plan a maintenance schedule: Coordinate with production to schedule tasks during downtime or when the impact on production is minimal.

- Delegate tasks based on skill level: Assign simple tasks to less experienced technicians and complex tasks to more experienced ones.

- Monitor progress and adjust resources: Track the progress of tasks and reallocate resources as needed to meet deadlines.

5. What are the key safety procedures to be followed when operating cutting machines?

- Wear appropriate safety gear: Safety glasses, gloves, and ear protection.

- Ensure proper machine setup: Verify that the machine is correctly installed and calibrated.

- Inspect the material: Look for potential hazards like sharp edges or loose debris.

- Follow operating instructions: Refer to the machine’s manual for proper operating procedures.

- Never put hands or fingers near the blade: Use tools or push sticks to manipulate materials.

6. Describe the importance of preventative maintenance for cutting machines and how you implement it.

- Reduces breakdowns and downtime: Regular maintenance helps identify and fix minor issues before they become major problems.

- Extends machine life: Proper maintenance ensures optimal performance and durability.

- Improves safety: Regular inspections and maintenance minimize the risk of accidents and injuries.

- Optimizes production: Well-maintained machines operate efficiently, reducing scrap and production delays.

7. How do you work effectively with production personnel to coordinate maintenance activities?

- Communicate clearly: Discuss maintenance schedules, potential downtime, and any special requirements with production staff.

- Collaborate on planning: Plan maintenance tasks to minimize disruption to production and meet production deadlines.

- Provide feedback: Inform production personnel about the status of maintenance tasks and any potential issues or delays.

- Seek feedback: Gather feedback from production personnel about machine performance and any concerns they may have.

8. What is your experience with using diagnostic tools to troubleshoot cutting machine issues?

- Electrical testers: Voltmeters, ammeters, and multimeters to diagnose electrical faults.

- Hydraulic/pneumatic testers: Pressure gauges, flow meters, and leak detectors to identify hydraulic/pneumatic issues.

- Computer-aided diagnostic software: Software tools to diagnose and resolve machine control and software errors.

- Mechanical gauges: Dial indicators, micrometers, and calipers to measure and inspect machine components.

9. How do you stay up-to-date with the latest cutting machine technology and industry best practices?

- Attend industry events and conferences: Network with professionals and learn about new technologies and practices.

- Read trade publications and online resources: Stay informed about industry trends and best practices.

- Engage in online forums and discussions: Connect with other professionals and share knowledge and ideas.

- Participate in training and certification programs: Enhance skills and knowledge through structured training.

10. How do you handle situations where a cutting machine requires complex repairs that are beyond your expertise?

- Consult technical manuals and diagrams: Review technical documentation to understand the machine’s design and functionality.

- Seek guidance from experienced technicians: Reach out to colleagues or manufacturers for assistance and advice.

- Contact the manufacturer for support: Engage with the manufacturer’s technical support team for guidance and spare parts.

- Outsource to specialized repair companies: If necessary, hire external experts to handle complex repairs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutting Machine Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutting Machine Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cutting Machine Fixer is a highly skilled and experienced technician responsible for maintaining, repairing, and troubleshooting cutting machines in a manufacturing or production environment. The key job responsibilities include:

1. Troubleshooting and Repair

Identify and diagnose faults in cutting machines, such as hydraulic, electrical, or mechanical issues.

- Analyze machine components and identify faulty parts.

- Repair and replace defective parts using specialized tools and techniques.

2. Maintenance and Calibration

Perform regular maintenance and calibration to ensure optimal machine performance and accuracy.

- Lubricate and clean machine components to prevent wear and tear.

- Adjust and calibrate cutting tools and equipment to meet precise specifications.

3. Safety and Compliance

Maintain a safe and compliant work environment while operating cutting machines.

- Follow safety protocols and wear appropriate personal protective equipment (PPE).

- Ensure machines are in compliance with industry regulations and standards.

4. Training and Support

Provide technical support and training to machine operators and other staff.

- Train operators on safe and efficient machine operation.

- Troubleshoot machine issues and provide technical guidance to resolve them.

Interview Tips

To ace an interview for a Cutting Machine Fixer position, it is crucial to prepare thoroughly and showcase your skills and experience effectively.

1. Research the Company and Industry

Familiarize yourself with the company’s history, operations, and current projects. Research the industry trends and technological advancements related to cutting machines.

2. Highlight Your Skills and Experience

Emphasize your hands-on experience in troubleshooting, repairing, and maintaining cutting machines. Quantify your accomplishments with specific examples and metrics.

3. Demonstrate Problem-Solving Abilities

Prepare examples of how you successfully diagnosed and resolved complex machine issues. Explain your analytical approach and the steps you took to identify and fix the underlying problems.

4. Showcase Safety and Compliance Knowledge

Discuss your understanding of industry regulations and best practices for machine safety. Highlight your experience in implementing safety measures and ensuring compliance with occupational health and safety standards.

5. Prepare for Technical Questions

Review basic principles of hydraulics, electrical systems, and mechanics. Be prepared to answer questions about common machine components and troubleshooting techniques.

6. Practice Common Interview Questions

Practice answering common interview questions such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?”

7. Dress Professionally and Arrive on Time

Dress appropriately for the interview and arrive on time to demonstrate your professionalism and respect for the interviewer’s time.

Next Step:

Now that you’re armed with the knowledge of Cutting Machine Fixer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cutting Machine Fixer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini