Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cyanide Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

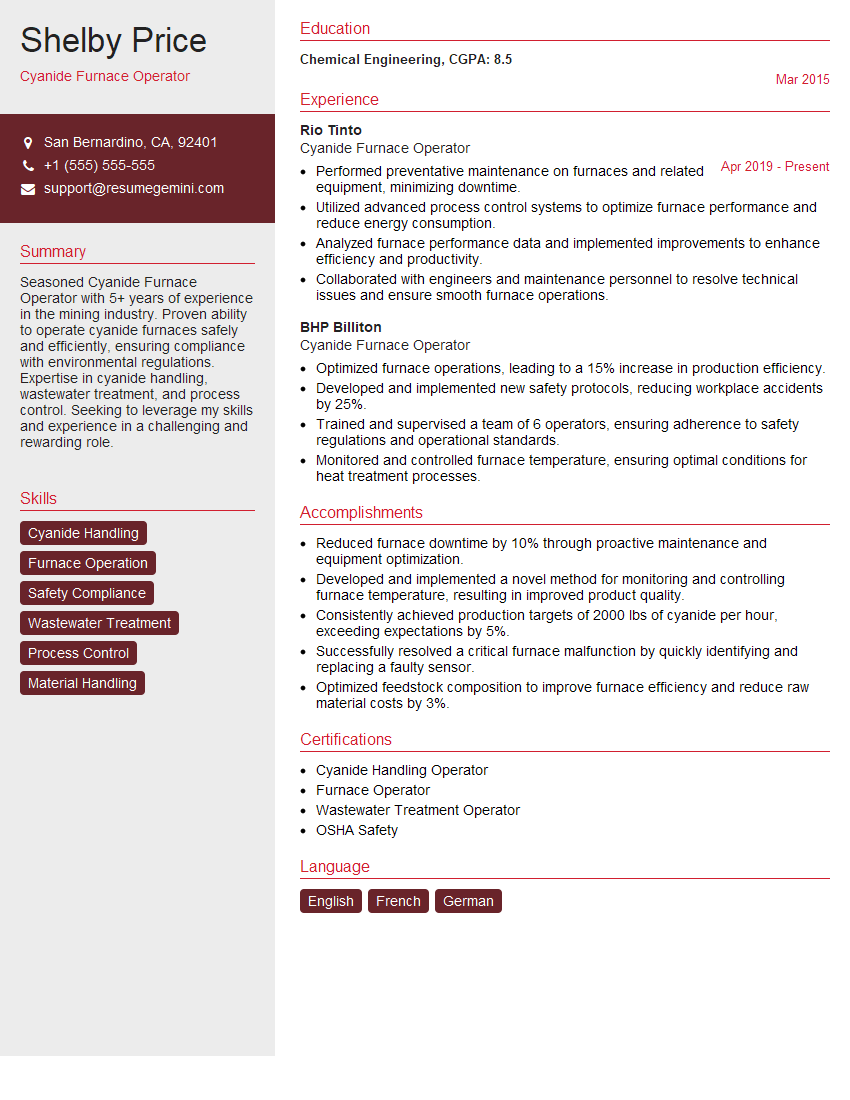

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cyanide Furnace Operator

1. Describe the key responsibilities of a Cyanide Furnace Operator?

As a highly skilled Cyanide Furnace Operator, I am responsible for a range of critical tasks, including:

- Operating, monitoring, and controlling cyanide furnaces to ensure safe and efficient functioning.

- Maintaining equipment, performing routine maintenance, and calibrating instruments to optimize furnace performance.

- Monitoring and controlling furnace temperature, pressure, and other process parameters to achieve desired results.

- Sampling and analyzing furnace products to ensure quality and adherence to specifications.

- Following safety protocols, handling hazardous materials, and adhering to environmental regulations.

2. Explain the process of cyanide destruction in a cyanide furnace?

Cyanidation Process:

- Cyanide is introduced into the furnace in the form of a solution or a solid.

- The solution is heated to a high temperature, typically above 1000°C (1832°F).

- At this temperature, the cyanide is converted into nitrogen gas, carbon monoxide, and water vapor.

Oxidation Process:

- Excess air is introduced into the furnace to ensure complete combustion.

- In the presence of oxygen, carbon monoxide is further oxidized to form carbon dioxide.

Cooling and Emission Treatment:

- The hot gases from the furnace are cooled down rapidly to prevent the formation of harmful byproducts.

- The cooled gases are passed through a series of scrubbers and filters to remove any remaining contaminants before being released into the atmosphere.

3. What are the safety precautions you take when working with cyanide?

Working with cyanide requires strict adherence to safety protocols to minimize potential risks. As a Cyanide Furnace Operator, I take the following precautions:

- Wearing appropriate personal protective equipment (PPE) including respirators, gloves, and protective clothing.

- Understanding the potential hazards and risks associated with cyanide exposure.

- Following proper handling and storage procedures for cyanide materials.

- Regularly monitoring cyanide levels in the work area to ensure they remain within safe limits.

- Maintaining a clean and organized work environment to minimize contamination.

4. How do you calibrate and maintain the instruments used in a cyanide furnace system?

Calibrating and maintaining instruments used in a cyanide furnace system are essential for accurate and reliable operation. I follow these steps:

- Adhering to manufacturer’s specifications and calibration schedules for each instrument.

- Using certified calibration standards and reference materials to ensure accuracy.

- Regularly performing routine checks and verifications to monitor instrument stability.

- Documenting and recording calibration data for traceability and quality control.

- Maintaining a preventive maintenance schedule to identify and address potential issues early on.

5. Describe the role of a Cyanide Furnace Operator in ensuring environmental compliance?

As a Cyanide Furnace Operator, I play a vital role in ensuring environmental compliance by:

- Adhering to all applicable environmental regulations and industry best practices.

- Minimizing cyanide emissions by optimizing furnace operations and maintaining proper control parameters.

- Monitoring and recording environmental parameters such as stack emissions, wastewater discharge, and noise levels.

- Working with environmental specialists to develop and implement pollution prevention measures.

- Participating in training programs and staying updated on environmental regulations to ensure compliance.

6. Explain how you handle and resolve operational issues that arise during cyanide furnace operations?

When operational issues arise during cyanide furnace operations, I follow a systematic approach to handle and resolve them:

- Identifying the issue and its potential causes through observation, data analysis, and troubleshooting.

- Consulting with colleagues, supervisors, or technical experts to gather additional insights and support.

- Implementing corrective actions based on the identified cause, while prioritizing safety and environmental compliance.

- Monitoring the effectiveness of corrective actions and making adjustments as needed to optimize furnace performance.

- Documenting the issue, resolution steps, and outcomes for future reference and knowledge sharing.

7. What is the importance of maintaining accurate records in a cyanide furnace operation?

Maintaining accurate records in a cyanide furnace operation is crucial for several reasons:

- Compliance: Records provide evidence of adherence to regulatory requirements and industry standards.

- Process Optimization: Analyzing records allows for identifying areas for improvement, optimizing furnace efficiency, and reducing operating costs.

- Safety and Environmental Management: Records document operational parameters, emissions data, and incidents, helping to ensure safety and environmental protection.

- Trouble Shooting: Records serve as a valuable resource for troubleshooting operational issues, identifying trends, and implementing corrective actions.

- Training and Knowledge Transfer: Records help train new operators and share knowledge about best practices and lessons learned.

8. How do you stay updated on the latest developments and best practices in cyanide furnace operations?

To stay updated on the latest developments and best practices in cyanide furnace operations, I engage in the following activities:

- Attending industry conferences, workshops, and seminars.

- Reading technical literature, journals, and industry publications.

- Networking with other professionals in the field.

- Participating in online forums and discussion groups.

- Completing continuing education courses and certifications.

9. Can you provide an example of a situation where you successfully resolved a complex issue related to cyanide furnace operations?

In a previous role, I encountered a situation where the cyanide furnace was experiencing unstable temperature fluctuations, leading to inconsistent product quality. I conducted a thorough investigation, analyzed furnace data, and consulted with experts. By implementing a combination of adjustments to fuel flow, air flow, and temperature control, I was able to resolve the issue, stabilize furnace operations, and achieve desired product specifications.

10. What are your career goals and how do you see your role as a Cyanide Furnace Operator contributing to your professional development?

My career goals align with continuously expanding my knowledge and skills in the field of cyanide furnace operations. I am keen on pursuing opportunities for professional growth, such as advanced training programs and certifications. As a Cyanide Furnace Operator, this role provides a solid foundation for me to develop a comprehensive understanding of furnace systems, safety protocols, and environmental regulations. I am confident that the hands-on experience and expertise gained in this position will significantly contribute to my long-term career aspirations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cyanide Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cyanide Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cyanide Furnace Operators are the backbone of operations in industries that utilize cyanide processes, such as electroplating, heat treatment, and mining. They play a crucial role in ensuring workplace safety and the production of high-quality products.

1. Cyanide Solution Preparation and Maintenance

Cyanide Furnace Operators are responsible for preparing and maintaining the cyanide solution used in electroplating and heat treatment processes. They must follow precise formulas and procedures to ensure the correct concentration and composition of the solution.

- Measure, mix, and maintain cyanide solutions according to specified concentrations.

- Perform regular quality checks to ensure the solution meets standards.

- Dispose of spent cyanide solutions in an environmentally responsible manner.

2. Furnace Operation and Maintenance

Operators are tasked with operating and maintaining cyanide furnaces to electroplate or heat treat metal components. They must continuously monitor furnace temperatures, voltage, and solution agitation to ensure optimal conditions.

- Load and unload metal components into the cyanide furnace.

- Monitor and adjust furnace parameters, including temperature, voltage, and agitation.

- Inspect furnace equipment for any damage or malfunctions.

3. Workplace Safety and Compliance

Cyanide Furnace Operators must adhere to strict safety regulations and guidelines to minimize the risk of cyanide exposure and accidents. They are required to wear personal protective equipment (PPE) and follow established safety protocols.

- Wear appropriate PPE, including gloves, respirators, and protective clothing.

- Follow all safety procedures and regulations to prevent cyanide exposure.

- Inspect and maintain safety equipment, such as fume hoods and emergency showers.

4. Quality Control and Troubleshooting

Operators play a role in maintaining product quality by monitoring the electroplating or heat treatment process and making adjustments as needed. They may also troubleshoot any issues that arise during production.

- Inspect electroplated or heat-treated components for defects.

- Identify and resolve any process deviations or problems.

- Maintain records and documentation related to the electroplating or heat treatment process.

Interview Tips

Preparing for a Cyanide Furnace Operator interview requires a combination of technical knowledge and a commitment to safety. Here are some tips to help you ace the interview.

1. Research the Company and Industry

Learn about the company’s business, products, and safety protocols. Research the industry’s best practices and regulations related to cyanide handling.

2. Highlight Your Technical Skills

Demonstrate your understanding of cyanide solution preparation, furnace operation, and quality control procedures. Provide specific examples of your experience in these areas.

3. Emphasize Your Safety Mindset

Convey your commitment to workplace safety and your knowledge of cyanide hazards. Describe your experience with PPE, emergency procedures, and environmental regulations.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your experience, technical skills, and safety practices. Examples include:

- Describe your experience with cyanide solution preparation and maintenance.

- How do you ensure the safe operation and maintenance of cyanide furnaces?

- What are the most important safety considerations when working with cyanide?

- How do you troubleshoot common problems that arise during electroplating or heat treatment?

5. Be Ready to Discuss Your Career Goals

Articulate your career aspirations and how the Cyanide Furnace Operator role aligns with your goals. Express your interest in contributing to the company’s success and your willingness to learn and grow.

Next Step:

Now that you’re armed with the knowledge of Cyanide Furnace Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cyanide Furnace Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini