Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cylinder Block Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

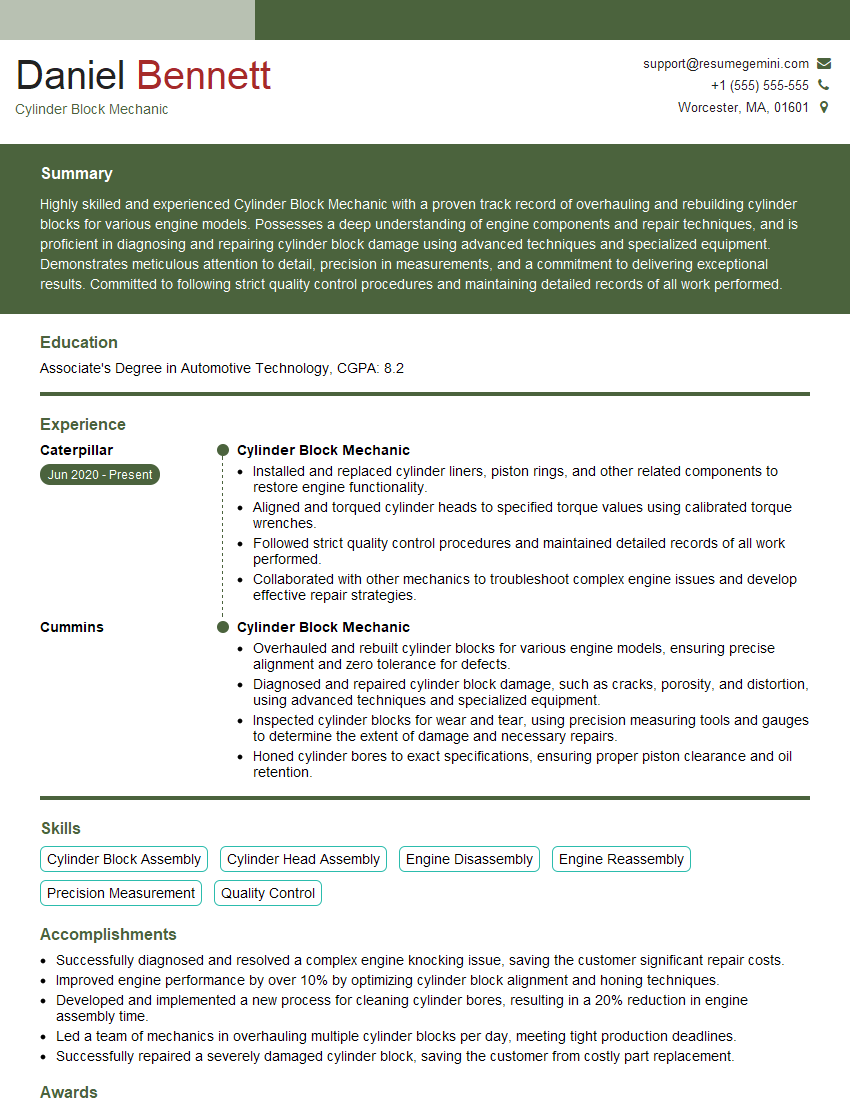

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cylinder Block Mechanic

1. What are the key responsibilities of a Cylinder Block Mechanic?

- Inspect and repair cylinder blocks for defects, wear, and damage

- Diagnose and repair engine problems related to the cylinder block

- Replace or repair cylinder liners, pistons, and other components as needed

- Maintain and repair cylinder block machinery and equipment

- Follow safety procedures and maintain a clean and organized work area

2. What are the different types of cylinder blocks?

Open-deck cylinder block

- Cylinders are not fully enclosed by the block

- Less rigid than closed-deck blocks

- Used in smaller engines

Closed-deck cylinder block

- Cylinders are fully enclosed by the block

- More rigid than open-deck blocks

- Used in larger engines

3. What are the different materials used to make cylinder blocks?

- Cast iron

- Aluminum

- Steel

4. What are the different machining processes used to manufacture cylinder blocks?

- Boring

- Honing

- Facing

- Milling

- Grinding

5. What are the different types of cylinder block failures?

- Cracks

- Warpage

- Bore wear

- Erosion

- Corrosion

6. What are the different methods used to repair cylinder blocks?

- Welding

- Stitching

- Brazing

- Boring and sleeving

- Line boring

7. What are the different types of cylinder block gaskets?

- Paper gaskets

- Metal gaskets

- Composite gaskets

8. What are the different types of cylinder head bolts?

- Stud bolts

- Cap screws

- Socket head bolts

9. What are the different types of cylinder head gaskets?

Describe the different types of cylinder head gaskets, including their materials, construction, and applications.

- Multi-layer steel (MLS) gaskets

- Head gaskets with fire rings

- Composite gaskets

10. What are the procedures for installing a cylinder head gasket?

Describe the detailed steps involved in installing a cylinder head gasket, including surface preparation, gasket placement, and torque specifications.

- Clean the cylinder head and block surfaces

- Apply a thin layer of gasket sealant to the cylinder head surface

- Place the gasket on the cylinder head and align it with the bolt holes

- Tighten the cylinder head bolts to the specified torque

11. What would you do if you encountered a cracked or damaged cylinder block?

Explain the steps you would take to diagnose and repair a cracked or damaged cylinder block.

- Visually inspect the cylinder block for cracks or damage

- Use a dye penetrant or magnetic particle inspection to identify cracks

- Determine the extent of the damage and decide on the best repair method

- Repair the crack or damage using welding, stitching, or brazing

12. How would you ensure that a cylinder block is properly reassembled after repairs?

Describe the procedures you would follow to ensure that a cylinder block is properly reassembled after repairs.

- Clean all mating surfaces

- Apply a thin layer of sealant to the mating surfaces

- Tighten all bolts to the specified torque

- Run the engine and check for leaks

13. What are the safety precautions that you should take when working on a cylinder block?

List the safety precautions that should be taken when working on a cylinder block.

- Wear appropriate safety gear, including safety glasses, gloves, and a hard hat

- Use caution when working with sharp tools and machinery

- Never work on a live engine

- Be aware of your surroundings and be careful not to trip or fall

14. Do you have any experience with working on different types of cylinder blocks?

Describe your experience with working on different types of cylinder blocks, including the specific makes and models of engines you have worked on.

- I have experience working on a variety of cylinder blocks, including those from domestic and foreign manufacturers

- I have worked on both gasoline and diesel engines

- I am familiar with the different types of cylinder block materials and construction

15. What are your career goals as a Cylinder Block Mechanic?

Describe your career goals as a Cylinder Block Mechanic and how this position fits into your plans.

- I am passionate about working on engines and I am always looking for ways to improve my skills

- I am eager to learn new techniques and technologies

- I believe that this position would be a great opportunity for me to grow my career and contribute to the success of your company

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cylinder Block Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cylinder Block Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cylinder Block Mechanics play a crucial role in maintaining and repairing engines. Their primary duties involve performing various inspections, overhauls, and repairs on cylinder blocks, ensuring their optimal functioning.

1. Cylinder Block Inspection and Diagnosis

Inspect cylinder blocks for defects, wear, and damage using precision measuring tools.

- Identify and assess the severity of cracks, warpage, and other issues.

- Determine the root cause of cylinder block failures and recommend appropriate repairs.

2. Cylinder Block Overhauling

Disassemble cylinder blocks and remove worn or damaged components.

- Clean and inspect cylinder walls, pistons, rings, and bearings.

- Replace faulty or worn components with new ones.

- Reassemble the cylinder block according to manufacturer specifications.

3. Cylinder Block Repair

Repair damaged cylinder blocks using specialized welding techniques.

- Weld cracks and damaged areas to restore structural integrity.

- Grind and machine the repaired surfaces to achieve precise tolerances.

4. Cylinder Block Testing

Conduct pressure tests and other diagnostic checks to ensure the repaired or overhauled cylinder block meets specifications.

- Test for leaks, cracks, and proper sealing.

- Verify the dimensional accuracy and functionality of the cylinder block.

Interview Preparation Tips

Preparing for an interview for a Cylinder Block Mechanic position requires a combination of technical knowledge and professional presentation. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and services.

- Review the job description and identify the specific skills and responsibilities required.

- Research industry trends and advancements in cylinder block repair techniques.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in cylinder block inspection, overhauling, repair, and testing.

- Quantify your accomplishments and provide specific examples of successful projects.

- Showcase your knowledge of different types of cylinder blocks, engines, and repair techniques.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to:

- Your understanding of cylinder block mechanics and repair principles.

- Your experience in troubleshooting and repairing cylinder block issues.

- Your knowledge of industry standards and safety protocols.

4. Ask Thoughtful Questions

Asking thoughtful questions demonstrates your interest and engagement.

- Inquire about the company’s approach to cylinder block maintenance and repair.

- Ask about the opportunities for professional development and technical growth.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cylinder Block Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.