Feeling lost in a sea of interview questions? Landed that dream interview for Cylinder Filler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cylinder Filler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

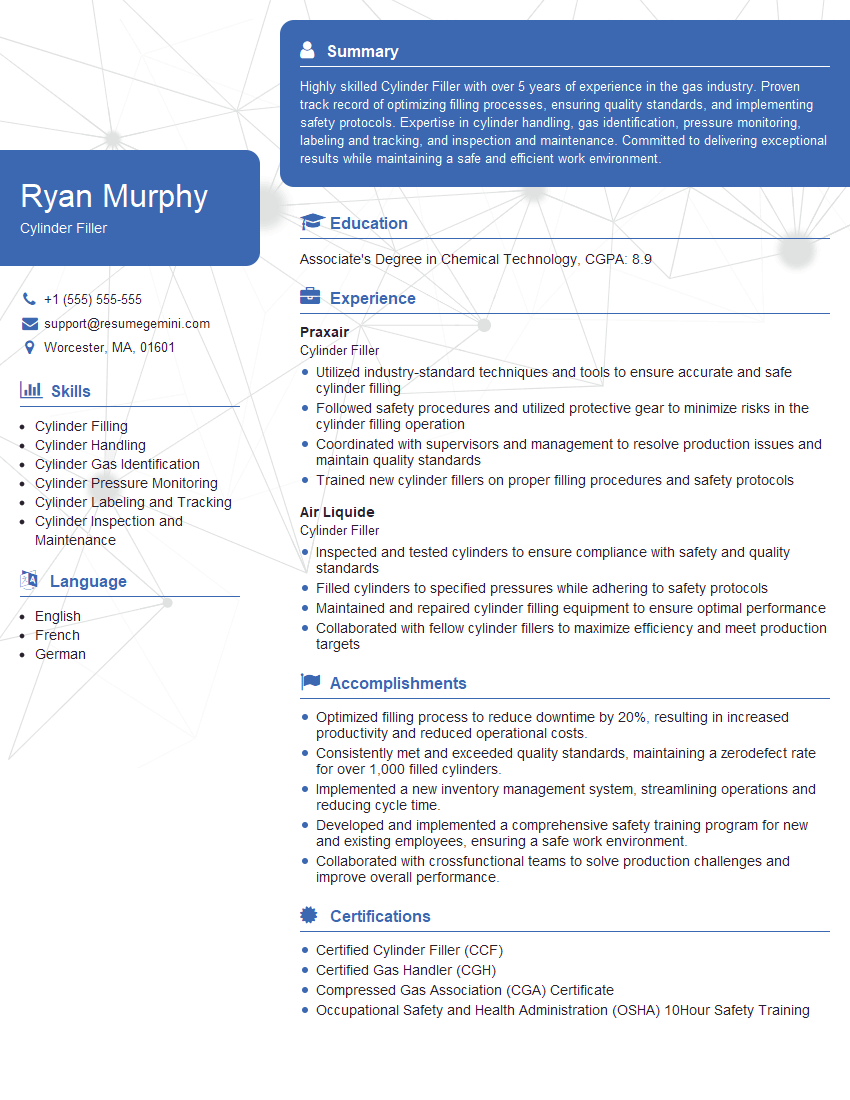

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cylinder Filler

1. Explain the process of cylinder filling, including the equipment and safety precautions involved?

- Prepare the cylinder by ensuring it is empty, clean, and leakage-free.

- Connect the cylinder to the filling station and secure it properly.

- Purge the cylinder to remove any air or contaminants.

- Fill the cylinder with the specified gas to the required pressure.

- Disconnect the cylinder and label it with the date, type of gas, and pressure.

- Safety precautions include wearing proper PPE, ensuring the filling station is well-ventilated, and following established procedures.

2. How do you determine the correct filling pressure for different types of cylinders?

Referencing Specifications

- Consult manufacturer’s guidelines or industry standards to determine the specified filling pressure for each type of cylinder.

- Consider the cylinder’s material, capacity, and intended use.

Using Pressure Gauges

- Attach a pressure gauge to the cylinder and fill it to the recommended pressure.

- Observe the gauge reading and ensure it matches the specified filling pressure.

3. Describe the different types of cylinder valves and how to handle them safely?

- Pin-Index Valves: Align the valve’s index pin with the corresponding notch on the cylinder to connect and disconnect.

- CGA Valves: Screw the valve onto the cylinder hand-tight and use a spanner wrench to tighten further.

- DIN Valves: Engage the valve’s lever with the cylinder’s valve body and tighten manually.

- Safety Tips: Always wear gloves, inspect valves for damage, use appropriate tools, and avoid overtightening.

4. Explain the importance of leak testing cylinders and how you conduct it?

- Importance: Detects leaks that could compromise safety, cause gas loss, or damage equipment. Methods:

- Soap Bubble Test: Apply soapy water to the cylinder’s connections and valves. Bubbles indicate leaks.

- Electronic Leak Detectors: Use specialized detectors to pinpoint leaks with greater sensitivity.

- Hydrostatic Testing: Submerge the cylinder in water under pressure to detect any structural weaknesses or leaks.

5. How do you handle and store cylinders safely?

- Transport: Secure cylinders upright with straps or chains, protect valves with caps, and ensure proper ventilation.

- Storage: Store cylinders in a well-ventilated, dry, and secure area away from heat sources and incompatible materials.

- Inspection: Regularly inspect cylinders for damage, leaks, and proper labeling.

- Handling: Use proper lifting techniques, wear gloves, and avoid rolling or dragging cylinders.

6. Describe the different types of gases that you can fill into cylinders?

- Industrial Gases: Oxygen, Nitrogen, Argon, Helium, CO2

- Medical Gases: Oxygen, Nitrous Oxide, Helium-Oxygen

- Specialty Gases: Calibration gases, mixtures, and research-grade gases

- Flammable Gases: Propane, Butane, Acetylene (require special handling and precautions)

7. What are the common problems encountered during cylinder filling and how do you resolve them?

- Leaks: Check valves, connections, and gaskets for damage or wear. Tighten or replace as needed.

- Overfilling: Use a pressure gauge and stop filling when the specified pressure is reached.

- Contamination: Purge the cylinder properly before filling and use clean equipment.

- Valve Failure: Replace or repair faulty valves immediately, following manufacturer’s instructions.

8. How do you ensure the quality of the gas filled into cylinders?

- Gas Source: Obtain gas from reputable suppliers with quality control measures.

- Cylinder Inspection: Examine cylinders for cleanliness, damage, and proper labeling before filling.

- Filling Equipment: Maintain and calibrate filling equipment regularly to ensure accurate pressure and purity.

- Quality Control: Conduct random checks on filled cylinders to verify gas purity and pressure.

9. Explain the importance of proper documentation and record-keeping in cylinder filling?

- Safety: Provides a record of filling procedures, equipment used, and gas specifications in case of incidents.

- Traceability: Enables tracking of cylinders, gas sources, and filling dates for quality control and inventory management.

- Compliance: Meets regulatory requirements and industry standards for documentation and record-keeping.

10. How do you stay up-to-date with the latest safety regulations and industry best practices for cylinder filling?

- Attend Industry Conferences and Seminars: Participate in events that provide updates on regulations and best practices.

- Read Trade Publications and Journals: Stay informed about advancements in cylinder filling technology and safety measures.

- Consult with Experts: Seek guidance from experienced professionals, manufacturers, and industry associations.

- Continuing Education: Enroll in courses or workshops to enhance knowledge and skills in cylinder filling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cylinder Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cylinder Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cylinder Fillers are responsible for the safe and efficient filling of gas cylinders with various gases, such as oxygen, nitrogen, and argon. They ensure that the cylinders are filled to the correct specifications and are properly labeled and handled. In addition, they may also be responsible for maintaining and servicing the filling equipment.

1. Filling Cylinders

Cylinder Fillers are responsible for filling cylinders with the correct type and amount of gas. They must follow strict safety protocols to ensure that the cylinders are filled safely and efficiently. They also need to be able to identify different types of cylinders and know how to properly connect them to the filling equipment.

- Follow safety protocols to ensure the safe and efficient filling of cylinders.

- Identify and properly connect different types of cylinders to the filling equipment.

2. Labeling and Handling Cylinders

Once the cylinders are filled, Cylinder Fillers are responsible for labeling them with the correct information. This information includes the type of gas, the quantity of gas, and the date of filling. They also need to be able to handle the cylinders safely and securely.

- Label cylinders with the correct information, including the type of gas, quantity of gas, and date of filling.

- Handle cylinders safely and securely to prevent accidents.

3. Maintaining and Servicing Filling Equipment

Cylinder Fillers are also responsible for maintaining and servicing the filling equipment. This includes inspecting the equipment for any damage or wear, and making sure that it is operating properly. They may also be responsible for troubleshooting any problems that occur with the equipment.

- Inspect the filling equipment for any damage or wear.

- Make sure that the filling equipment is operating properly.

- Troubleshoot any problems that occur with the filling equipment.

4. Other Responsibilities

In addition to the above responsibilities, Cylinder Fillers may also be responsible for:

- Training new employees on how to fill cylinders.

- Supervising other Cylinder Fillers.

- Working with customers to resolve any issues.

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go on an interview, it is important to do your research. This includes learning about the company, the position you are applying for, and the industry. This will help you to answer questions intelligently and show that you are genuinely interested in the opportunity.

- Visit the company’s website to learn about its history, mission, and values.

- Read articles and news stories about the company to get a sense of its current position in the industry.

- Look at the job description for the position you are applying for to understand the specific requirements.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Write down your answers to common interview questions and practice saying them out loud.

- Ask a friend or family member to mock interview you.

- Use online resources to find sample interview questions and answers.

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of an interview shows that you are engaged and interested in the opportunity. It also gives you a chance to learn more about the company and the position. Prepare a few questions in advance that you can ask the interviewer.

- What are the biggest challenges facing the company right now?

- What are the opportunities for growth within the company?

- What is the company culture like?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the opportunity.

- Dress in a suit or business casual attire.

- Arrive at the interview location 10-15 minutes early.

- Be polite and respectful to everyone you meet.

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Don’t try to be someone you’re not.

- Be confident in your abilities.

- Let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cylinder Filler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!