Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cylinder Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

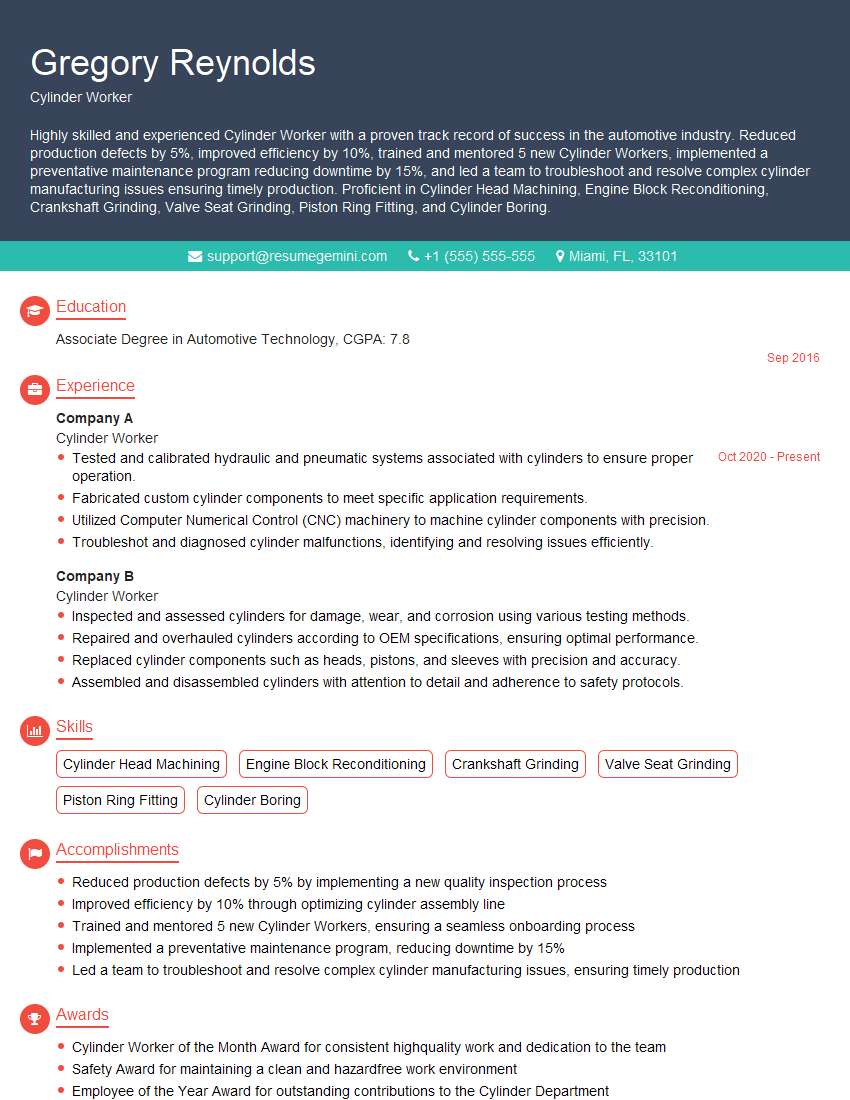

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cylinder Worker

1. Explain the process of measuring and recording cylinder dimensions and clearances?

- Utilize precision measuring tools such as micrometers, bore gauges, and dial gauges to accurately measure cylinder dimensions, including bore diameter, piston ring groove depth, and cylinder wall thickness.

- Record measurements diligently in logbooks or electronic databases, ensuring accuracy and traceability.

- Compare measured values against specifications to determine clearances, such as piston-to-cylinder clearance and ring-to-groove clearance.

- Identify any deviations from specifications and report them promptly to supervisors for further evaluation.

2. How do you evaluate cylinder surface conditions and identify potential defects?

Visual Inspection

- Visually examine cylinder surfaces using specialized lighting and magnification tools.

- Detect and identify surface defects such as scratches, scoring, pitting, and wear patterns.

- Assess the severity of defects by considering factors like depth, length, and location.

Surface Roughness Measurement

- Use surface roughness gauges to measure the texture and finish of cylinder walls.

- Determine whether roughness values meet specifications and contribute to proper piston ring sealing.

- Identify potential sources of excessive wear and take corrective actions.

3. Describe your methods for resurfacing and honing cylinders?

- Select the appropriate honing tool and abrasive stones based on cylinder material and desired surface finish.

- Set honing parameters, including speed, feed, and stroke rate, to achieve desired cross-hatch pattern and surface roughness.

- Lubricate the cylinder wall during honing to minimize friction and ensure proper stone performance.

- Inspect honed surface meticulously to verify it meets specifications and provides optimal ring-to-cylinder sealing.

4. How do you ensure that cylinder head gaskets are properly installed and torqued?

- Clean mating surfaces of the cylinder head and engine block to remove any contaminants.

- Position the cylinder head gasket correctly, ensuring alignment with dowel pins or locating features.

- Use a torque wrench to tighten head bolts or studs to specified torque values in the proper sequence.

- Verify gasket integrity by visually inspecting for leaks or coolant seepage after engine operation.

5. Explain the importance of proper piston ring installation and how you verify their correct orientation?

- Identify the top, second, and oil control rings based on their design and markings.

- Ensure that piston rings are installed with the correct side facing up, as indicated by markings or chamfers.

- Use a piston ring compressor to compress the rings and facilitate their insertion into the cylinder.

- Check ring gaps using feeler gauges to verify they are within specifications and provide adequate sealing.

6. Describe your procedures for inspecting and assessing piston and connecting rod assemblies?

Piston Inspection

- Examine piston surfaces for signs of wear, scoring, or cracks.

- Measure piston ring grooves to ensure they meet tolerance specifications.

- Verify piston pin bore diameter and fit to ensure proper pin clearance.

Connecting Rod Inspection

- Inspect for bending, twisting, or cracks in the connecting rod.

- Measure big and small end bearing diameters to determine wear and clearance.

- Check piston pin fit in the connecting rod eye for proper fit and alignment.

7. Explain the techniques you use to troubleshoot and resolve issues related to cylinder performance?

- Use compression testing equipment to identify cylinders with low or uneven compression, indicating potential issues with valves, piston rings, or cylinder integrity.

- Perform leak-down tests to pinpoint specific areas of leakage, such as valves, piston rings, or head gaskets.

- Inspect cylinder bores for excessive wear, damage, or glazing that may affect engine performance.

- Analyze engine operating data and diagnostic codes to identify potential causes of cylinder-related problems.

8. How do you prioritize your workload and manage multiple tasks effectively in a fast-paced environment?

- Establish a clear understanding of priorities and deadlines with supervisors.

- Use a task management system to organize and track work assignments.

- Break down large tasks into smaller, manageable steps to maintain focus.

- Delegate tasks to team members when appropriate to optimize workflow.

9. Describe a situation where you successfully resolved a complex technical issue related to cylinder operations?

- Highlight the problem, including symptoms and potential causes.

- Explain the diagnostic steps taken to identify the root cause of the issue.

- Describe the corrective actions implemented and their impact on resolving the problem.

- Emphasize the skills and knowledge utilized to achieve a successful outcome.

10. Explain how you stay up-to-date with industry best practices and technological advancements in cylinder repair?

- Attend industry conferences and workshops to learn about new techniques and equipment.

- Subscribe to trade publications and online resources for ongoing updates.

- Participate in manufacturer training programs to enhance skills and knowledge.

- Collaborate with colleagues and external experts to exchange ideas and stay informed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cylinder Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cylinder Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cylinder Workers are responsible for the maintenance, repair, and calibration of cylinders and related equipment used in various industrial settings. Their key responsibilities include:

1. Cylinder Maintenance

Inspecting cylinders for leaks, corrosion, dents, and other defects.

- Cleaning and lubricating cylinders to ensure smooth operation.

- Tightening or replacing cylinder fittings and valves.

- Performing routine checks and adjustments to maintain optimal performance.

- Inspecting and replacing O-rings, seals, and other components.

2. Cylinder Repair

Assessing the extent of damage to cylinders and recommending repair options.

- Repairing or replacing damaged cylinder heads, pistons, rods, and other components.

- Welding and fabricating new parts to restore cylinder functionality.

- Testing repaired cylinders to ensure proper operation and safety.

- Maintaining records of cylinder repairs and replacements.

3. Cylinder Calibration

Calibrating cylinders to ensure they meet industry standards and specifications.

- Using specialized equipment to test cylinder pressure, flow rate, and other parameters.

- Adjusting cylinders to meet required tolerances and accuracy levels.

- Labeling or tagging cylinders to indicate their calibrated status.

- Maintaining calibration records for each cylinder.

- Performing regular calibration checks to verify continued accuracy.

4. Related Equipment Maintenance

Inspecting, cleaning, and maintaining other equipment related to cylinders, such as valves, regulators, and piping.

- Identifying and resolving equipment malfunctions and breakdowns.

- Replacing worn or damaged components and ensuring proper assembly.

- Testing equipment to verify proper operation and safety.

- Maintaining records of equipment maintenance and repairs.

Interview Tips

To ace an interview for a Cylinder Worker position, candidates should prepare thoroughly and demonstrate their knowledge, skills, and experience in the field. Here are some interview tips and hacks:

1. Research the Company and Position

Research the company’s history, products, services, and industry reputation. Understand the specific requirements of the Cylinder Worker position and how your skills and experience align with them.

- This demonstrates your interest in the company and your understanding of the role.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your experience in cylinder maintenance, repair, and calibration. Quantify your accomplishments whenever possible, using specific examples to showcase your abilities.

- For example, instead of saying “I repaired cylinders,” you could say “I repaired over 500 cylinders within a 6-month period, ensuring their safe and efficient operation.”

3. Showcase Attention to Detail

Cylinder Workers need to be highly attentive to detail to ensure the accuracy and safety of their work. Emphasize your ability to inspect cylinders thoroughly, identify potential issues, and take meticulous measurements.

- Give examples of situations where your attention to detail has led to successful outcomes, such as identifying a minor defect that prevented a potential equipment failure.

4. Demonstrate Problem-Solving Abilities

Cylinder Workers often encounter unforeseen challenges. Highlight your ability to troubleshoot problems, analyze data, and find practical solutions. Provide examples of complex issues you have resolved in the past.

- For example, you could share how you diagnosed and fixed a recurring cylinder leak that had stumped other technicians.

5. Prepare Questions

Ask thoughtful questions at the end of the interview. This shows that you are engaged and interested in the position. Prepare questions about the company’s safety protocols, equipment calibration procedures, or any other aspects that you find intriguing.

- Well-prepared questions can also help you gauge the company’s culture and values.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cylinder Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.