Are you gearing up for an interview for a Dairy Chemist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dairy Chemist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

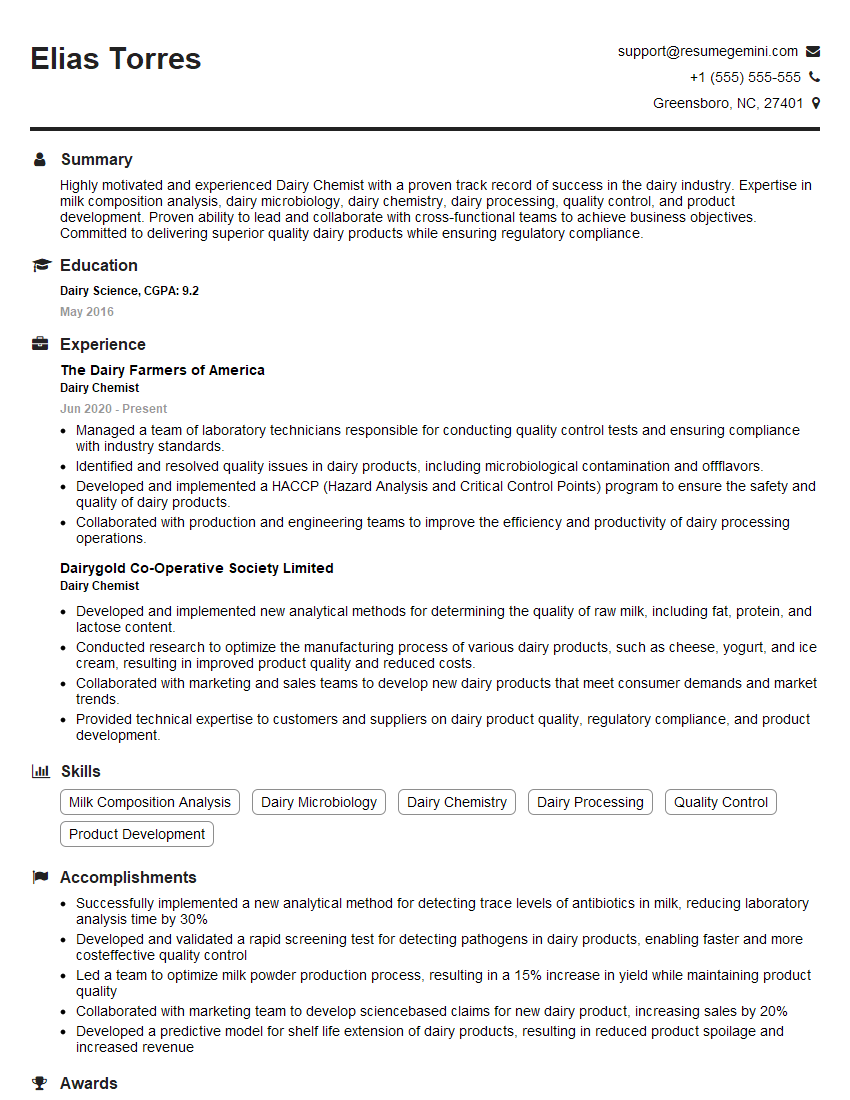

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dairy Chemist

1. Explain the factors that affect the stability of dairy emulsions?

The stability of dairy emulsions is influenced by several factors, including:

- Emulsifier type and concentration: The type and concentration of emulsifier play a crucial role in stabilizing emulsions. Emulsifiers reduce interfacial tension, preventing droplets from coalescing.

- Droplet size distribution: Smaller droplets are more stable than larger droplets. Emulsions with a narrow droplet size distribution are less susceptible to creaming and coalescence.

- pH: pH can affect the charge on the surface of droplets, influencing their stability. Electrostatic repulsion between droplets can prevent coagulation.

- Ionic strength: High ionic strength can reduce electrostatic repulsion and promote droplet aggregation.

- Temperature: Temperature fluctuations can cause changes in droplet size and stability. Emulsions may become less stable at higher temperatures due to increased molecular motion.

2. Describe the different methods used to analyze the composition of dairy products?

Various analytical methods are employed to determine the composition of dairy products:

- Kjeldahl method: Determines nitrogen content, which can be used to calculate protein content.

- Mojonnier method: Measures fat content by extracting fat with solvents.

- Gravimetric method: Determines moisture content by drying a sample and measuring the weight loss.

- Titration methods: Used to determine acidity, pH, and calcium content.

- Spectrophotometry: Employs light absorption or emission to quantify specific components, such as lactose or vitamins.

- Chromatography techniques: HPLC or GC can separate and identify different components, such as fatty acids or amino acids.

3. Discuss the role of enzymes in dairy processing?

Enzymes play a significant role in various aspects of dairy processing:

- Milk coagulation: Enzymes like rennet and chymosin are used to coagulate milk proteins for cheese production.

- Lactose conversion: Lactase enzyme is employed to convert lactose into glucose and galactose, creating lactose-reduced or lactose-free products.

- Proteolysis: Proteases can be used to modify the texture of dairy products, enhance flavor, or produce hydrolysates.

- Lipolysis: Lipases are utilized to break down fats and produce fatty acids and glycerol.

- Preservation: Enzymes like lysozyme and lactoperoxidase can be added to dairy products to inhibit spoilage bacteria.

4. Explain the principles behind ultra-high temperature (UHT) processing of milk?

UHT processing involves heating milk to extremely high temperatures (typically 135-150°C) for a short period (2-4 seconds) to achieve microbial inactivation:

- Microorganism destruction: UHT treatment effectively destroys spoilage and pathogenic microorganisms, extending the shelf life of milk.

- Inactivation of enzymes: UHT temperatures inactivate enzymes that can cause undesirable changes in milk quality, such as proteases and lipases.

- Nutritional value retention: UHT processing retains most of the nutritional value of milk, including proteins, minerals, and vitamins.

- Aseptic packaging: UHT-processed milk is typically packaged aseptically to prevent recontamination.

5. Describe the different types of dairy starter cultures and their applications?

Dairy starter cultures are bacteria that ferment lactose and produce lactic acid:

- Lactic acid bacteria (LAB): LAB are commonly used in yogurt, cheese, and fermented milk production.

- Mesophilic cultures: Ferment at moderate temperatures (25-35°C) and are used in products like cottage cheese and sour cream.

- Thermophilic cultures: Ferment at higher temperatures (40-45°C) and are employed in products like Swiss cheese and mozzarella.

- Probiotic cultures: Certain LAB strains with health-promoting properties are used in probiotic dairy products like yogurt and kefir.

6. Explain the importance of milk homogenization and its effects on milk properties?

Milk homogenization reduces fat globule size and distributes them evenly throughout the milk:

- Improved stability: Homogenization prevents fat separation and creaming, prolonging shelf life.

- Enhanced digestibility: Smaller fat globules are more easily digested, improving bioavailability.

- Uniform texture: Homogenized milk has a smoother and more consistent texture.

- Reduced fat clumping: Homogenization improves the stability of fat-based dairy products like ice cream and whipped cream.

7. Discuss the principles behind cheese ripening and the factors that influence it?

- Cheese ripening: A complex process involving enzymatic, microbial, and biochemical changes that impart unique flavors and textures to cheese.

- Factors influencing ripening:

- Moisture content: Higher moisture content promotes microbial growth and enzymatic activity.

- pH: Lower pH inhibits microbial growth and enzymes.

- Temperature: Different temperatures favor specific microbial and enzymatic reactions.

- Salt content: Salt inhibits microbial growth but enhances flavor development.

- Mold and bacteria: Specific molds and bacteria contribute to characteristic flavors and textures.

8. Explain the role of calcium in dairy products and its impact on their nutritional value?

Calcium is a crucial mineral in dairy products:

- Bone health: Calcium is essential for strong bones and teeth.

- Muscle function: Calcium aids in muscle contraction and relaxation.

- Nerve transmission: Calcium is involved in nerve impulse transmission.

- Blood clotting: Calcium plays a role in blood coagulation.

- Fortified dairy products: Dairy products can be fortified with calcium to enhance their nutritional value.

9. Discuss the challenges associated with the development of lactose-free dairy products?

Producing lactose-free dairy products presents several challenges:

- Lactose intolerance: Lactose intolerance is the inability to digest lactose due to insufficient lactase enzyme.

- Lactose removal: Lactose removal methods include enzymatic hydrolysis or membrane filtration, which can affect flavor and texture.

- Sweetness loss: Lactose contributes to the sweetness of dairy products, requiring alternative sweeteners to maintain palatability.

- Texture modification: Lactose removal can impact the texture of dairy products, necessitating stabilizers or thickeners.

- Cost and availability: Lactose-free dairy products may have higher production costs and limited availability compared to regular dairy products.

10. Describe the emerging trends and innovations in the dairy industry?

- Alternative dairy sources: Plant-based and cultured dairy alternatives are gaining popularity.

- Functional dairy products: Dairy products enriched with probiotics, prebiotics, or other functional ingredients.

- Precision dairy farming: Technologies to optimize milk production and animal health.

- Sustainability: Focus on reducing environmental impact in dairy production.

- Dairy bioprocessing: Utilizing enzymes and microorganisms to enhance dairy product quality and functionalities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dairy Chemist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dairy Chemist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dairy Chemists are responsible for ensuring the safety and quality of dairy products. They conduct various chemical and physical tests on raw materials and finished products to ensure they meet industry standards. Their key responsibilities include:1. Quality Control and Analysis:

- Conduct chemical and physical tests on raw milk, dairy ingredients, and finished products

- Analyze test results to ensure compliance with food safety and quality standards

- Develop and implement quality control procedures to maintain product consistency and safety

2. Product Development and Improvement:

- Collaborate with product development teams to create new dairy products

- Conduct research to improve existing products and processes

- Analyze consumer feedback to identify areas for product improvement

3. Regulatory Compliance and Hazard Analysis:

- Stay updated on food safety regulations and industry best practices

- Conduct hazard analysis and critical control point (HACCP) analyses

- Develop and implement corrective actions to address potential food safety hazards

4. Technical Support and Troubleshooting:

- Provide technical support to production and quality control teams

- Troubleshoot product quality issues and identify root causes

- Recommend solutions to optimize production processes and product quality

Interview Tips

Preparing thoroughly for a Dairy Chemist interview is crucial for success. Here are some tips to help you ace the interview:1. Research the Company and Position:

- Learn about the dairy industry and the company’s products and services

- Review the job description carefully to identify the key qualifications and responsibilities

- Research the company’s mission, values, and culture to ensure alignment with your own

2. Highlight Your Qualifications and Skills:

- Showcase your knowledge of dairy chemistry, quality control, and food safety regulations

- Emphasize your analytical, problem-solving, and technical troubleshooting abilities

- Provide examples of your experience in developing or improving dairy products

3. Practice Your Answers:

- Prepare answers to common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

- Rehearse your answers out loud to improve your delivery and confidence

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples

4. Dress Professionally and Arrive On Time:

- First impressions matter, so dress professionally and arrive punctually

- Maintain eye contact, smile, and speak clearly throughout the interview

- Be respectful of the interviewer’s time and questions

5. Ask Questions and Follow Up:

- Prepare thoughtful questions to ask the interviewer about the company, the role, and the industry

- Asking questions shows your interest and engagement

- After the interview, follow up with a thank-you note to reiterate your interest and express your appreciation

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dairy Chemist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!