Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dairy Equipment Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

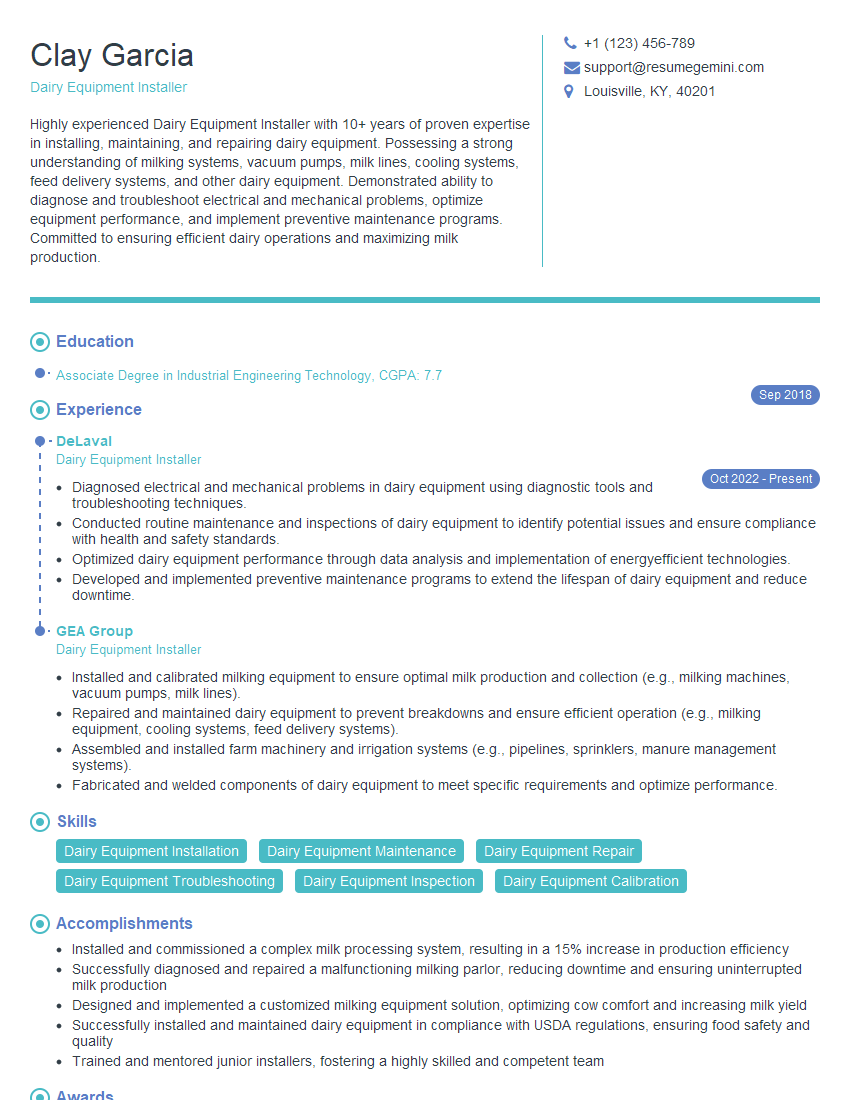

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dairy Equipment Installer

1. Describe the process of installing a bulk milk cooler?

The process of installing a bulk milk cooler typically involves the following steps:

- Site preparation: This involves selecting a suitable location for the cooler, ensuring it is level and has adequate drainage.

- Cooler assembly: The cooler is assembled according to the manufacturer’s instructions.

- Refrigeration unit installation: The refrigeration unit is installed and connected to the cooler.

- Piping and electrical connections: The cooler is connected to the milk line and electrical power supply.

- Testing and commissioning: The cooler is tested to ensure it is functioning correctly and meets the required specifications.

2. What are the safety precautions that need to be taken when working with dairy equipment?

Electrical safety:

- Always follow electrical codes and regulations.

- Inspect electrical equipment regularly for damage or defects.

- Never work on live electrical equipment.

Mechanical safety:

- Wear appropriate personal protective equipment (PPE) when working with machinery.

- Lock out and tag out equipment before performing maintenance or repairs.

- Be aware of pinch points and other hazards.

3. How do you troubleshoot a milking machine that is not functioning properly?

Troubleshooting a milking machine that is not functioning properly involves the following steps:

- Check the power supply and ensure that the machine is receiving electricity.

- Inspect the vacuum system for leaks or blockages.

- Check the milk line for kinks or obstructions.

- Examine the milking claws and teats cups for damage or wear.

- Consult the manufacturer’s manual for specific troubleshooting instructions.

4. What are the different types of milking systems and their advantages and disadvantages?

Pipeline milking systems:

- Advantages: High capacity, efficient milk transfer, labor-saving.

- Disadvantages: High installation cost, requires a dedicated milking parlor.

Bucket milking systems:

- Advantages: Low installation cost, portable, suitable for small herds.

- Disadvantages: Labor-intensive, lower milk quality.

Rotor milking systems:

- Advantages: High throughput, gentle on cows, labor-saving.

- Disadvantages: High installation cost, requires specialized training.

5. What are the key maintenance tasks that need to be performed on dairy equipment?

- Regular cleaning and disinfection of all equipment that comes into contact with milk.

- Inspection and lubrication of moving parts.

- Testing and calibration of monitoring devices.

- Replacement of worn or damaged parts as needed.

6. How do you ensure the quality of milk during the milking process?

- Maintaining a clean and sanitary milking environment.

- Properly preparing cows before milking (cleaning udders, stripping foremilk).

- Using milking equipment that is in good working condition.

- Cooling milk rapidly after milking.

- Performing regular milk quality tests.

7. What are the common problems that can occur with dairy equipment and how do you resolve them?

Vacuum system problems:

- Leakage: Check for leaks in the vacuum lines and repair as necessary.

- Blockage: Clear any blockages in the vacuum lines.

Milking machine problems:

- Faulty pulsation: Inspect the pulsation system and replace any worn or damaged parts.

- Insufficient vacuum: Check the vacuum pump and ensure it is operating correctly.

8. How do you stay up-to-date on the latest technologies and trends in dairy equipment?

- Attending industry conferences and trade shows.

- Reading industry publications and technical journals.

- Consulting with experts and manufacturers.

9. How do you handle working in a demanding and fast-paced environment?

- Prioritize tasks effectively and manage time efficiently.

- Stay organized and focused under pressure.

- Communicate effectively with colleagues and supervisors.

10. Why are you interested in working as a Dairy Equipment Installer?

I am interested in working as a Dairy Equipment Installer because I have a passion for the dairy industry and a strong interest in the technical aspects of dairy equipment. I believe that my skills and experience in equipment installation and maintenance would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dairy Equipment Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dairy Equipment Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dairy Equipment Installers are responsible for installing, maintaining, repairing, and servicing dairy equipment in dairies and other food processing facilities. They work with a variety of equipment, including milking machines, bulk tanks, and pipelines.

1. Installation

Dairy Equipment Installers typically start by installing new equipment. This involves unloading the equipment from a truck, assembling it, and connecting it to the appropriate utilities. They must also ensure that the equipment is level and properly aligned.

- Follow blueprints and schematics to plan and layout equipment

- Assemble and install dairy equipment, such as milking machines, bulk tanks, and pipelines

2. Maintenance

Once the equipment is installed, Dairy Equipment Installers are responsible for maintaining it. This involves regularly inspecting the equipment for wear and tear, and performing necessary repairs. They also lubricate the equipment and keep it clean.

- Inspect and test dairy equipment to ensure proper functionality

- Troubleshoot and repair mechanical and electrical problems

3. Repair

If the equipment breaks down, Dairy Equipment Installers are responsible for repairing it. This may involve replacing parts, adjusting settings, or performing other repairs.

- Diagnose and repair electrical, mechanical, and hydraulic systems

- Replace worn or damaged parts

4. Service

In addition to installation, maintenance, and repair, Dairy Equipment Installers also provide service to their customers. This may involve providing training on how to use the equipment, answering questions, or providing technical support.

- Provide training and technical support to customers

- Update and maintain records of equipment maintenance and repairs

Interview Tips

Interviewing for a Dairy Equipment Installer position can be competitive. Here are a few tips to help you ace the interview:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website and social media pages

- Read industry news and articles

- Talk to people who work or have worked for the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- List out your skills and experience

- Prepare examples of your work

- Practice answering questions in front of a mirror or with a friend

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Be punctual and arrive a few minutes early

- Bring a portfolio or resume with you

4. Be yourself and be enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. The interviewer wants to get to know you and see if you are a good fit for the company.

- Be honest and genuine in your answers

- Show your passion for the dairy industry

- Ask questions about the company and the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dairy Equipment Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!