Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dairy Equipment Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

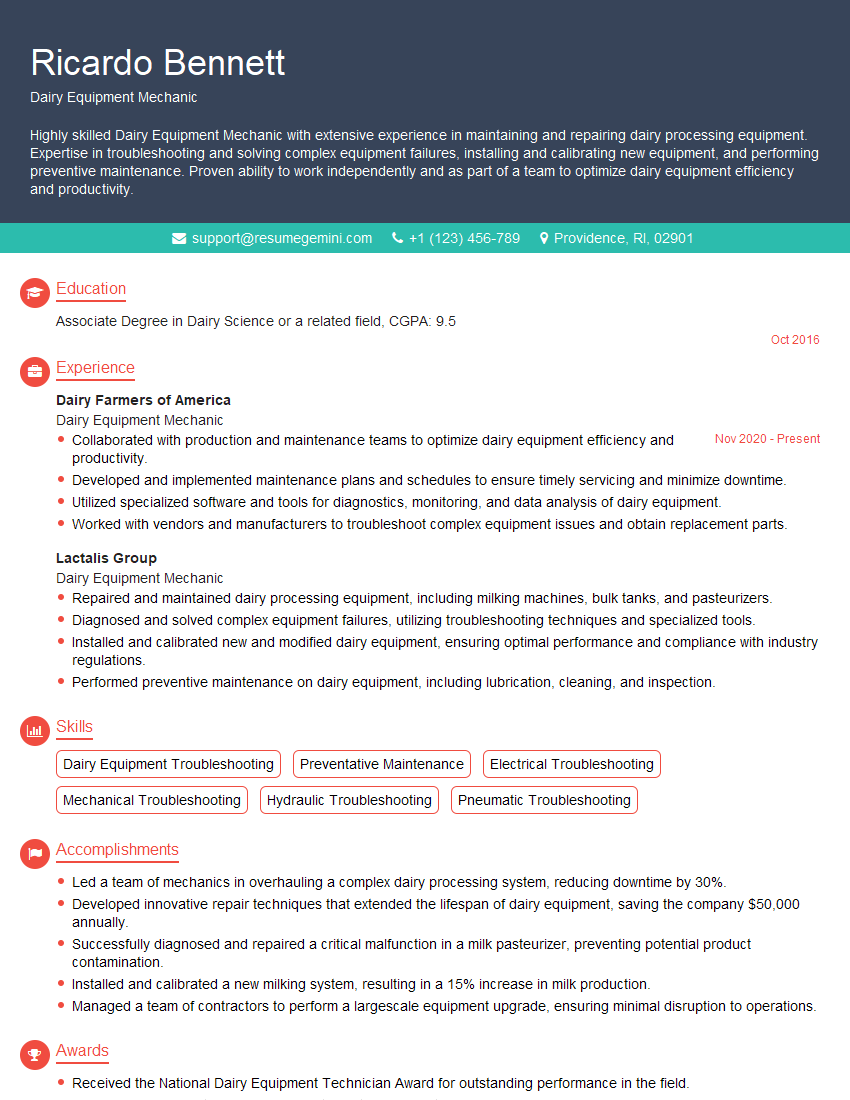

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dairy Equipment Mechanic

1. What troubleshooting steps would you take if a milk pump is not working?

To troubleshoot a milk pump that is not working, I would follow these steps:

- Check power supply: Ensure the pump is plugged in and receiving power.

- Inspect hoses and connections: Check for any leaks, kinks, or blockages that could restrict milk flow.

- Examine the pump impeller: Remove the pump cover and inspect the impeller for damage or debris that may hinder its rotation.

- Test the motor: Disconnect the motor from the pump and use a multimeter to test its continuity and resistance. Replace if faulty.

- Examine the pressure gauge: If the pump is not building pressure, the pressure gauge may be faulty. Calibrate or replace as needed.

- Check for cavitation: Listen for any suction noises that may indicate cavitation, caused by insufficient suction pressure.

2. How do you maintain and calibrate a milking machine?

Daily Maintenance:

- Clean and inspect milking units and teat cups for damage.

- Lubricate moving parts according to manufacturer’s specifications.

- Check vacuum levels and adjust as necessary.

Regular Calibration:

- Vacuum pump: Test vacuum level and adjust if outside optimal range (usually 12-15 inches of mercury).

- Milk flow meter: Calibrate using a milk bucket and stopwatch to ensure accurate measurement of milk yield.

- Pulsator: Set the pulsation rate and ratio according to manufacturer’s recommendations for cow comfort and milk production.

3. What safety precautions should be observed when working on electrical equipment in a dairy environment?

- Ensure equipment is properly grounded to prevent electrical shocks.

- Use insulated tools and wear appropriate clothing, including rubber gloves and safety glasses.

- Lock out and tag out power sources before performing any repairs or maintenance.

- Be aware of wet or slippery conditions that may increase the risk of electrical hazards.

- Follow electrical safety standards and manufacturer’s guidelines.

- Have a qualified electrician or technician inspect and certify electrical installations regularly.

4. Describe the process of repairing a leaking milk tank.

- Locate the leak: Use a flashlight and inspect the tank for any visible holes or cracks.

- Prepare the area: Clean and dry the area around the leak to ensure proper adhesion.

- Apply sealant or adhesive: Apply a suitable sealant or adhesive to the leak, using a putty knife or caulking gun.

- Secure the patch: Use clamps or weights to hold the patch in place while it dries.

- Test the repair: Once dry, fill the tank with water or milk and inspect for any remaining leaks.

5. What are the common causes of bacterial contamination in dairy equipment?

- Improper cleaning and sanitization of equipment.

- Cross-contamination from dirty equipment or hands.

- Biofilm formation due to insufficient cleaning.

- Damaged or worn seals or gaskets.

- Inadequate storage of milk and dairy products.

6. What is the importance of preventative maintenance for dairy equipment?

- Reduces downtime and lost production.

- Maximizes the lifespan of equipment.

- Ensures optimal performance and efficiency.

- Promotes food safety and quality.

- Improves overall profitability of dairy operations.

7. What is the role of a Dairy Equipment Mechanic in ensuring the safety of dairy products?

- Maintain and repair equipment: Keep equipment in good working order to prevent contamination and ensure proper milk handling.

- Monitor equipment performance: Regularly inspect and test equipment to identify any potential issues before they become major problems.

- Follow safety protocols: Adhere to established cleaning and sanitization procedures to prevent the spread of bacteria.

- Educate staff: Train dairy workers on proper equipment use and maintenance to reduce the risk of accidents or contamination.

8. Describe your experience in diagnosing and resolving complex equipment breakdowns.

In my previous role, I successfully diagnosed and resolved several complex breakdowns, including:

- Electrical fault in a milking parlor controller: Used a multimeter to trace the circuit and identify a faulty relay.

- Mechanical failure in a bulk tank agitator: Inspected the agitator and discovered a broken gear, which I replaced.

- Hydraulic leak in a manure handling system: Identified the source of the leak and repaired the damaged hose.

9. How do you stay up-to-date on the latest dairy equipment technologies and best practices?

- Attend industry conferences and workshops.

- Read trade publications and technical manuals.

- Network with other Dairy Equipment Mechanics.

- Pursue professional development opportunities through online courses or certification programs.

10. How do you prioritize your workload when faced with multiple urgent requests?

- Assess the urgency: Determine which requests have the highest priority based on potential impact on production or safety.

- Communicate with supervisors: Inform supervisors of the situation and seek guidance on prioritization.

- Delegate tasks: If possible, assign less urgent tasks to other team members.

- Use a scheduling system: Utilize a calendar or task management software to track deadlines and allocate time effectively.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dairy Equipment Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dairy Equipment Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Dairy Equipment Mechanic, you’ll play a pivotal role in ensuring the smooth operation of dairy equipment, ensuring efficient milk production and processing. Your primary responsibilities will include:

1. Equipment Maintenance and Repair

You’ll be responsible for diagnosing and repairing a wide range of dairy equipment, including milking machines, bulk tanks, conveyors, and refrigeration systems.

- Inspect equipment regularly to identify potential issues

- Troubleshoot equipment malfunctions and perform necessary repairs

2. Installation and Assembly

You may be involved in the installation and assembly of new or upgraded dairy equipment.

- Follow manufacturers’ specifications and safety protocols

- Complete installations within specified timeframes and budgets

3. Preventive Maintenance

To minimize breakdowns and costly repairs, you’ll implement a comprehensive preventive maintenance program.

- Schedule and conduct regular inspections and servicing

- Replace worn or damaged parts to ensure optimal equipment performance

4. Quality Control

You’ll be responsible for ensuring that dairy equipment meets safety and quality standards.

- Conduct quality checks on equipment throughout the production process

- Calibrate and adjust equipment to ensure accuracy and efficiency

Interview Tips

To ace your interview for a Dairy Equipment Mechanic position, follow these tips:

1. Research the Industry

Learn about the dairy industry, the specific equipment used, and the challenges faced by dairy farmers.

- Read industry publications and visit dairy farms

- Attend industry events and webinars

2. Highlight Your Skills and Experience

Emphasize your mechanical skills, knowledge of dairy equipment, and experience in troubleshooting and repairing.

- Quantify your accomplishments using specific metrics

- Provide examples of how you’ve resolved complex technical issues

3. Demonstrate Your Safety Awareness

Safety is paramount in dairy operations. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Explain how you follow lockout/tagout procedures

- Describe your experience in handling hazardous materials

4. Show Your Commitment to Continuous Learning

Technology in the dairy industry is constantly evolving. Show the interviewer that you’re committed to staying abreast of advancements.

- Discuss any certifications or training programs you’ve completed

- Share your plans for future professional development

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dairy Equipment Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!