Are you gearing up for a career in Dairy Equipment Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dairy Equipment Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

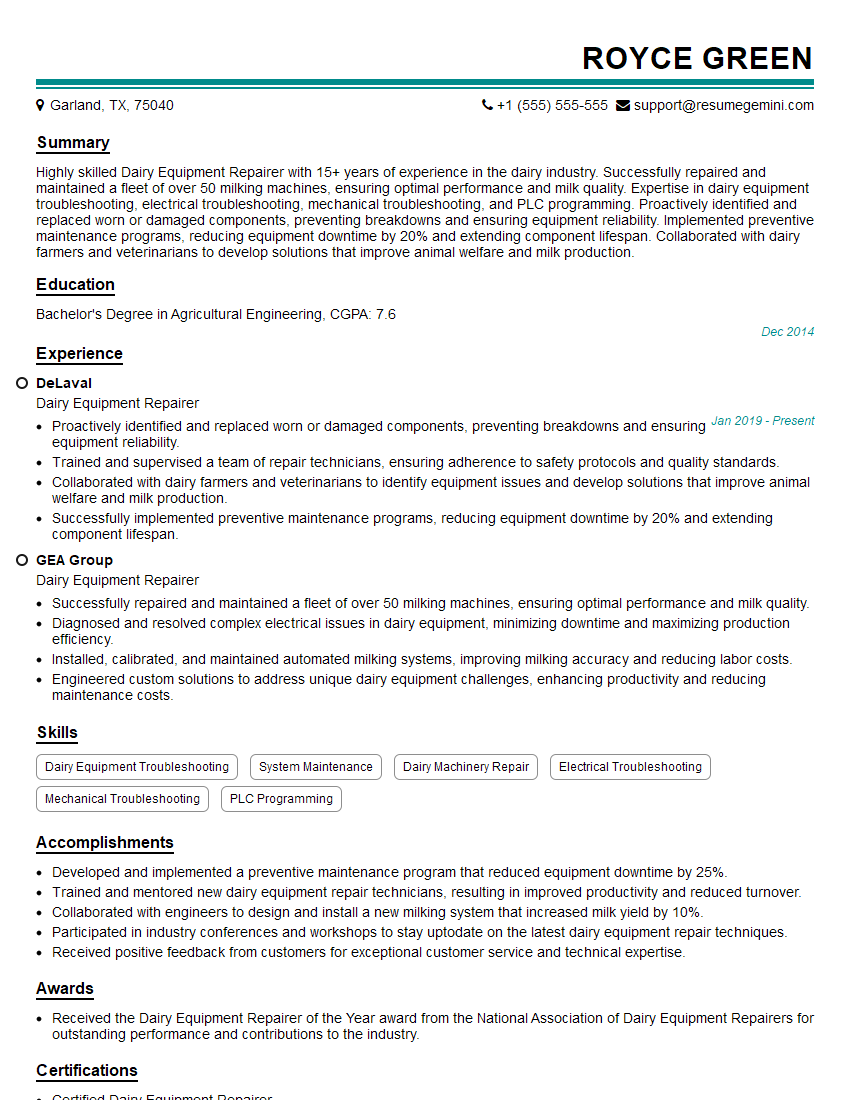

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dairy Equipment Repairer

1. What are the common problems you have encountered while repairing dairy equipment? How did you resolve them?

- Diagnosed and repaired electrical faults in milking machines, such as motor failures, wiring issues, and control system malfunctions.

- Troubleshooted and fixed mechanical problems with milking equipment, including vacuum pumps, vacuum lines, and milking claws.

- Identified and replaced worn or damaged parts in dairy equipment, such as milking liners, pulsators, and teat cups.

2. What are the different types of milking machines and their respective maintenance requirements?

Electric Milking Machines:

- Regular inspection of electrical components, wiring, and motors.

- Cleaning and lubrication of moving parts.

Gas-Powered Milking Machines:

- Monitoring fuel levels and spark plug condition.

- Checking and adjusting carburetor settings.

3. Describe the steps involved in calibrating a milking machine.

- Check the vacuum level using a vacuum gauge.

- Adjust the regulator to achieve the desired vacuum setting.

- Test the milking machine with a bucket of water to ensure proper milk flow.

- Fine-tune the calibration to optimize milking efficiency and cow comfort.

4. What tools and equipment do you typically use for dairy equipment repair?

- Multimeter

- Vacuum gauge

- Wrenches

- Screwdrivers

- Pliers

- Diagnostic software

5. How do you ensure the safety of yourself and others while working on dairy equipment?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures to prevent accidental startup during repair.

- Maintain a clean and organized work area.

- Inspect equipment thoroughly before performing any repairs.

6. Describe your experience with preventive maintenance and predictive maintenance of dairy equipment.

- Performed regular inspections and cleaning of milking equipment to identify potential issues early.

- Monitored equipment performance data to detect changes or anomalies that could indicate potential failures.

- Used diagnostic tools to assess the condition of critical components and make informed decisions on repairs or replacements.

7. How do you stay updated with the latest advancements in dairy equipment repair techniques?

- Attend industry conferences and workshops.

- Read technical publications and articles.

- Participate in online forums and discussion groups.

8. Describe a situation where you had to work under pressure to repair critical dairy equipment. How did you handle it?

- Maintained composure and remained focused on the task at hand.

- Prioritized repairs based on urgency and potential impact on milking operations.

- Communicated effectively with supervisors and colleagues to ensure timely and effective repair.

9. What is your approach to troubleshooting complex dairy equipment issues?

- Gather information about the symptoms and operating history of the equipment.

- Perform a visual inspection to identify potential causes.

- Use diagnostic tools to test components and identify faults.

- Consult with experienced colleagues or industry experts if necessary.

10. How do you document your repair work and ensure traceability for future reference?

- Maintain detailed repair records, including equipment identification, issue description, repairs performed, and parts replaced.

- Use a computerized maintenance management system (CMMS) to track repair history and access information quickly.

11. What are the key factors to consider when selecting replacement parts for dairy equipment?

- Compatibility with the equipment model and specific component.

- Quality and durability of the part.

- Availability and cost of the part.

12. How do you ensure the accuracy and reliability of your repairs?

- Follow established repair procedures and industry best practices.

- Use calibrated test equipment and tools.

- Perform thorough testing of the repaired equipment before returning it to service.

13. How do you handle customer complaints and ensure their satisfaction with your repair services?

- Listen attentively to the customer’s concerns and complaints.

- Investigate the issue thoroughly and provide a clear explanation of the cause and solution.

- Communicate regularly with the customer throughout the repair process.

- Follow up with the customer after the repair to ensure their satisfaction.

14. What is your understanding of the importance of maintaining hygiene and sanitation standards in dairy equipment repair?

- Preventing the spread of bacteria and contamination of dairy products.

- Ensuring the health and safety of consumers.

- Maintaining the reputation and integrity of the dairy industry.

15. How do you prioritize repair tasks and manage your workload effectively?

- Assess the urgency and potential impact of each repair task.

- Create a work schedule and prioritize tasks based on their criticality.

- Delegate tasks to other team members when necessary.

- Use a work order system to track the status of repairs and manage workload.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dairy Equipment Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dairy Equipment Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Dairy Equipment Repairer, you will be responsible for a wide range of tasks essential to the smooth operation of a dairy farm or processing plant. Here are some of the key responsibilities you can expect:

1. Equipment Maintenance and Repairs

You will be responsible for conducting routine maintenance and repairs on various dairy equipment, including milking machines, milk storage tanks, pasteurizers, separators, and other specialized machinery.

- Inspect and diagnose equipment issues.

- Perform repairs, replacements, and adjustments.

- Maintain and update equipment records.

2. Troubleshooting and Problem Solving

You will need to be able to troubleshoot and solve problems quickly and efficiently to minimize downtime. This may involve:

- Identifying the root cause of equipment failures.

- Developing and implementing solutions to address issues.

- Collaborating with other team members to resolve complex problems.

3. Safety Compliance

Ensuring the safety of yourself and others is paramount. Your responsibilities include:

- Adhering to all safety regulations and protocols.

- Identifying and mitigating potential hazards.

- Training and supervising junior staff on safety practices.

4. Customer Service

Providing excellent customer service is crucial. You will interact with dairy farmers, plant managers, and other stakeholders to:

- Understand their equipment needs and concerns.

- Provide technical support and advice.

- Build and maintain strong relationships.

Interview Tips

To ace your interview for a Dairy Equipment Repairer position, here are some tips to help you prepare:

1. Research the Company and Industry

- Visit the company website to learn about their business, values, and recent developments.

- Read industry publications and articles to stay up-to-date on the latest equipment and trends.

2. Practice Answering Common Interview Questions

- Prepare answers to common interview questions related to your skills, experience, and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Your Technical Skills

- Emphasize your expertise in repairing and maintaining dairy equipment.

- Discuss your knowledge of different equipment models and manufacturers.

- Provide examples of complex repairs you have successfully completed.

4. Showcase Your Problem-Solving Abilities

- Describe how you approach troubleshooting and problem-solving.

- Share examples of how you have identified and resolved equipment issues efficiently.

- Demonstrate your creativity and ability to think outside the box.

5. Dress Professionally and Be Punctual

- First impressions matter. Dress appropriately for the occasion and arrive for your interview on time.

- Maintain a professional demeanor and show enthusiasm for the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dairy Equipment Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dairy Equipment Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.