Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dairy Processing Equipment Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

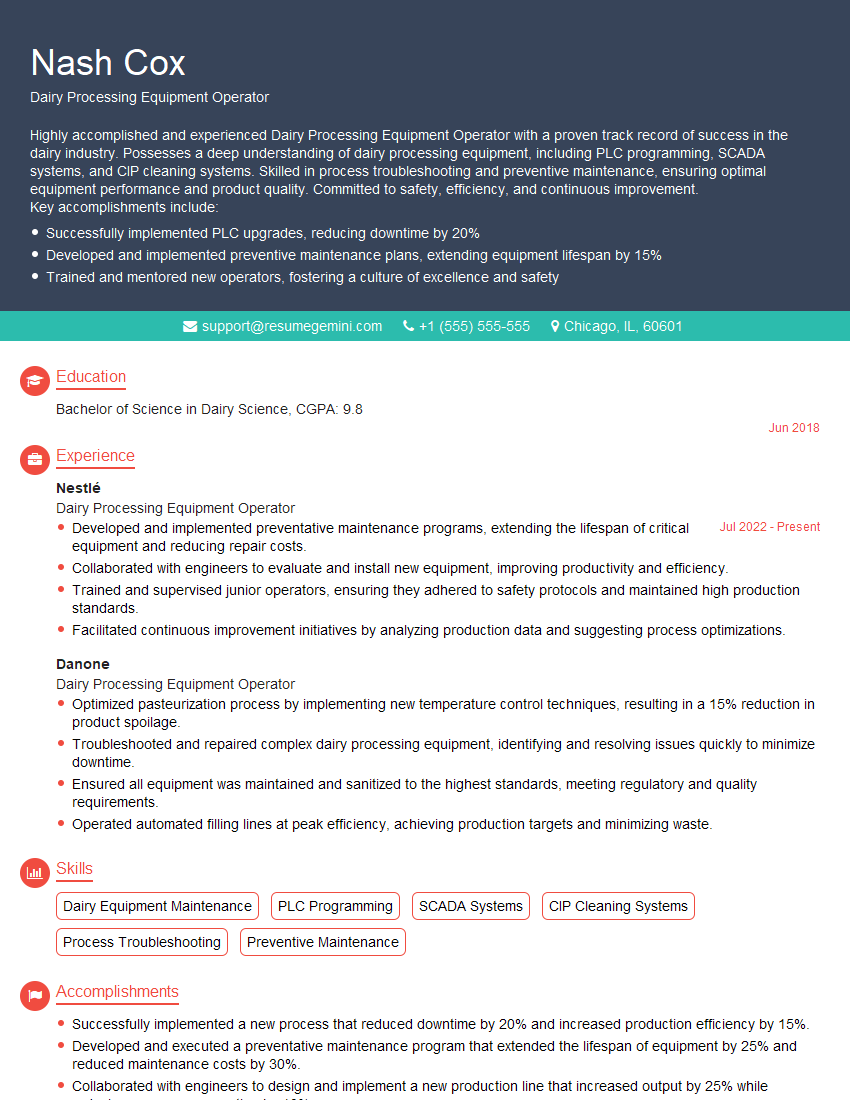

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dairy Processing Equipment Operator

1. Describe the overall process of how milk is processed and packaged in a dairy processing plant.

The processing of milk in a dairy processing plant involves several key steps to ensure its safety, quality, and shelf life:

- Receiving and Inspection: Raw milk is received from farms and inspected for quality and temperature.

- Filtration and Clarification: Milk is filtered to remove impurities and clarified to remove any remaining particles.

- Standardization and Homogenization: The milk is standardized to adjust its fat content and homogenized to prevent fat separation.

- Pasteurization: Milk is heated to a specific temperature to kill harmful bacteria.

- Cooling: The pasteurized milk is rapidly cooled to prevent bacterial growth.

- Packaging: The milk is packaged in various containers, such as bottles, cartons, or bags, and labeled with information.

- Storage and Distribution: The packaged milk is stored and distributed to retail stores or consumers.

2. What are the different types of dairy processing equipment that you are familiar with?

I have experience working with various types of dairy processing equipment, including:

- Pasteurizers (HTST and UHT systems)

- Homogenizers

- Separators

- Evaporators

- Spray dryers

- Filling and packaging machines

- Cleaning and sanitizing equipment

3. How do you ensure that the equipment you operate is maintained and sanitized properly?

Maintaining and sanitizing dairy processing equipment is crucial to prevent contamination and ensure the safety of products. I follow these steps:

- Regular Inspection: I conduct daily visual inspections of equipment for any signs of wear, damage, or leaks.

- Cleaning: I clean equipment as per established schedules using approved cleaning agents and methods.

- Sanitizing: After cleaning, I sanitize equipment with approved sanitizers according to manufacturer’s instructions.

- Monitoring: I monitor temperatures and pressures during cleaning and sanitizing processes to ensure effectiveness.

- Documentation: I maintain accurate records of all cleaning and sanitizing procedures for traceability.

4. What are some common troubleshooting techniques you use when there is a problem with the equipment?

When troubleshooting equipment issues, I follow these steps:

- Identify the Problem: I observe the equipment, listen for unusual sounds, and check gauges to identify the issue.

- Consult Documentation: I refer to equipment manuals and troubleshooting guides for guidance.

- Inspect Equipment: I visually inspect the equipment for any obvious damage or leaks.

- Test and Adjust: I perform tests and make adjustments as needed to resolve the issue, following established protocols.

- Seek Assistance: If I am unable to resolve the issue myself, I contact a qualified technician for support.

5. How do you ensure the quality of the products you produce?

To ensure product quality, I adhere to the following practices:

- Follow SOPs: I strictly follow standard operating procedures (SOPs) for all processes.

- Monitor Process Parameters: I monitor temperature, pressure, and other critical process parameters to maintain consistency.

- Conduct Product Testing: I perform regular product testing to ensure it meets specifications.

- Maintain Equipment: I ensure that equipment is properly calibrated and maintained to optimize performance.

- Training: I participate in ongoing training to stay up-to-date on best practices and quality control methods.

6. What is your understanding of HACCP principles and how do you apply them in your work?

HACCP (Hazard Analysis and Critical Control Points) is a preventive food safety system. I apply HACCP principles in my work:

- Identify Hazards: I identify potential hazards that could affect product safety.

- Determine Critical Control Points (CCPs): I establish CCPs where hazards can be controlled or eliminated.

- Establish Critical Limits: I set critical limits for each CCP to ensure product safety.

- Monitor CCPs: I monitor CCPs regularly to ensure they are within critical limits.

- Take Corrective Actions: I take immediate corrective actions when CCPs deviate from critical limits.

- Verify System: I verify the effectiveness of the HACCP system through regular monitoring and review.

7. Can you describe a situation where you had to make a decision that affected the safety or quality of a product?

In a previous role, I encountered an issue with the pasteurizer. The temperature gauge was malfunctioning, and I noticed that the milk was not reaching the required pasteurization temperature. I immediately stopped the process and alerted my supervisor. Together, we checked the equipment and confirmed the gauge malfunction. We recalibrated the gauge and resumed processing once the issue was resolved, ensuring the safety and quality of the pasteurized milk.

8. What are some safety precautions that you take when operating dairy processing equipment?

To ensure safety when operating dairy processing equipment, I adhere to these precautions:

- Follow SOPs and Lockout Procedures: I strictly follow established SOPs and lockout procedures.

- Wear Protective Gear: I wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Inspect Equipment: I conduct thorough pre-operation inspections of equipment to identify any hazards.

- Be Aware of Surroundings: I remain aware of my surroundings and potential hazards during operation.

- Report Hazards: I promptly report any observed hazards or unsafe conditions.

9. How do you stay up-to-date on advancements in dairy processing technology?

To stay current with advancements in dairy processing technology, I employ these strategies:

- Attend Industry Events: I participate in industry conferences, workshops, and trade shows.

- Read Fach Publications: I subscribe to industry magazines and journals to stay informed about new technologies.

- Network with Professionals: I connect with colleagues, vendors, and industry experts to exchange knowledge.

- Attend Training Programs: I participate in training programs offered by equipment manufacturers and industry organizations.

10. What are your long-term career goals within the dairy processing industry?

My long-term career goals within the dairy processing industry are:

- Advance my technical expertise: I am eager to continue expanding my knowledge and skills in dairy processing.

- Assume a leadership role: I aspire to take on supervisory or management responsibilities in the future.

- Contribute to industry advancements: I am passionate about applying my expertise to drive innovation and improve dairy processing practices.

- Ensure product safety and quality: I am committed to maintaining the highest standards of food safety and quality throughout my career.

- Support sustainability efforts: I am keen on contributing to sustainable and environmentally friendly dairy processing practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dairy Processing Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dairy Processing Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dairy Processing Equipment Operators are responsible for the safe and efficient operation of equipment in a dairy processing plant. Their duties include:

1. Equipment Operation

Operate and monitor dairy processing equipment, such as separators, homogenizers, and fillers.

- Ensure that equipment is running properly and make adjustments as necessary.

- Monitor product quality and make adjustments to equipment settings to maintain desired specifications.

2. Equipment Maintenance

Perform basic maintenance on dairy processing equipment, such as cleaning, lubrication, and minor repairs.

- Identify and report any equipment malfunctions or breakdowns.

- Assist in major repairs and overhauls as needed.

3. Sanitation and Safety

Maintain a clean and sanitary work environment.

- Follow all safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

4. Quality Assurance

Monitor product quality and take corrective action as needed.

- Collect and analyze product samples.

- Work with quality control personnel to ensure that products meet specifications.

Interview Tips

To ace your interview for a Dairy Processing Equipment Operator position, follow these tips:

1. Research the company and the position

Learn about the dairy processing plant and the specific role you are applying for. This will help you understand the company’s culture and values, as well as the day-to-day responsibilities of the job.

- Visit the company’s website.

- Read online reviews and articles about the company.

- Talk to people you know who work in the dairy industry.

2. Prepare your answers to common interview questions

There are certain questions that you are likely to be asked in an interview for a Dairy Processing Equipment Operator position. Prepare your answers to these questions in advance so that you can deliver them confidently and clearly.

- Tell me about your experience with dairy processing equipment.

- What are your strengths and weaknesses as a Dairy Processing Equipment Operator?

- Why are you interested in working for this company?

- What are your salary expectations?

- Do you have any questions for me?

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and polished shoes.

Also, be sure to arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the job.

4. Be enthusiastic and positive

Dairy Processing Equipment Operators are typically responsible for working in a fast-paced, demanding environment. Interviewers will be looking for candidates who are enthusiastic about the work and who have a positive attitude.

During your interview, be sure to highlight your passion for the dairy industry and your commitment to providing quality products.

Next Step:

Now that you’re armed with the knowledge of Dairy Processing Equipment Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dairy Processing Equipment Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini