Are you gearing up for a career in Dairy Technologist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dairy Technologist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

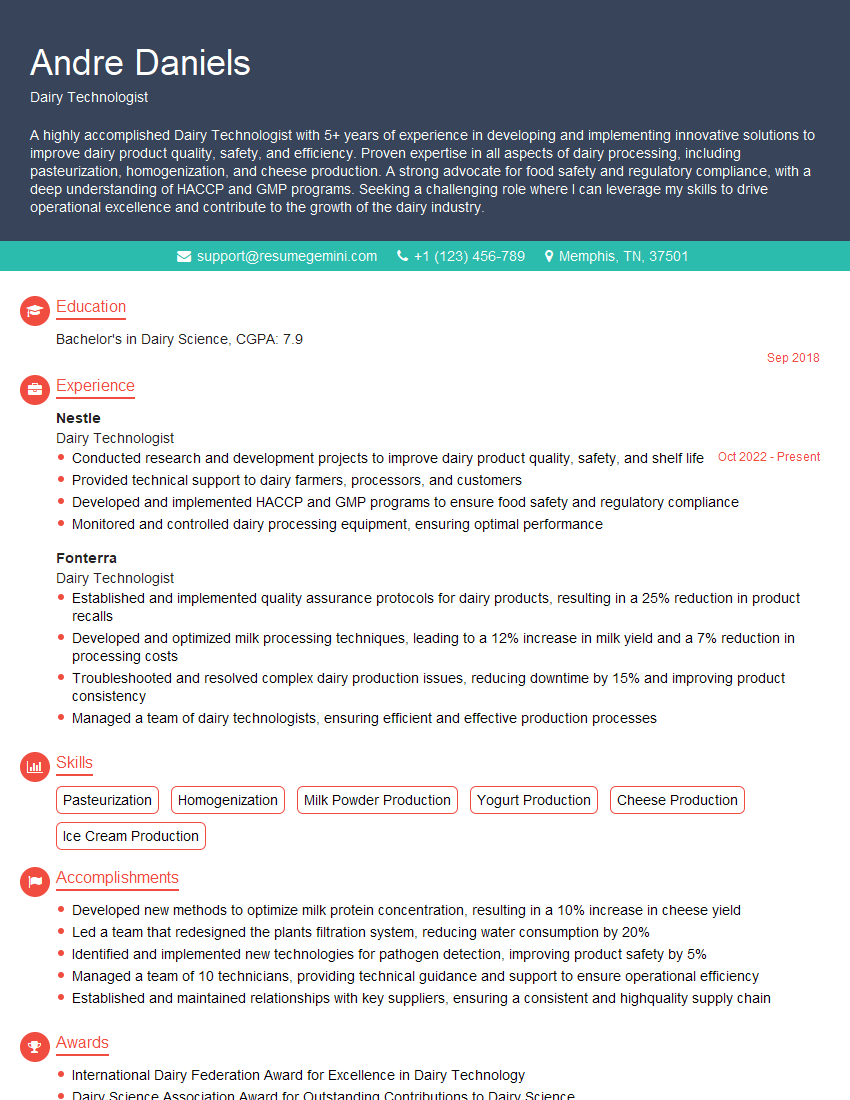

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dairy Technologist

1. Describe the process of pasteurization and its significance in dairy industry?

Pasteurization is a heat treatment process that kills harmful bacteria and pathogens in milk and other dairy products. It is named after Louis Pasteur, a French scientist who developed the process in the 19th century.

- Significance of Pasteurization in the Dairy Industry:

- Ensures the safety of dairy products by eliminating pathogenic bacteria such as Salmonella, E. coli, and Listeria.

- Extends the shelf life of dairy products by slowing down bacterial growth.

- Preserves the nutritional value of milk and other dairy products.

2. Explain the role of enzymes in cheese production?

Proteolytic Enzymes:

- Break down proteins in milk to form peptides and amino acids.

- Contribute to cheese texture, flavor, and ripening process.

Lipolytic Enzymes:

- Break down fats in milk to form fatty acids and glycerol.

- Contribute to cheese flavor and texture.

Lactic Acid Bacteria:

- Produce lactic acid during fermentation.

- Lower the pH of milk, coagulating proteins and forming curds.

3. Describe the factors affecting the quality of butter?

The quality of butter is influenced by several factors, including:

- Raw Material: Quality of milk and cream used.

- Processing Conditions: Temperature, duration of churning, and washing techniques.

- Starter Cultures: Type and amount of starter cultures used for fermentation.

- Salt Content: Amount and type of salt added.

- Packaging and Storage: Protect butter from light, air, and off-flavors.

4. Discuss the principles of membrane filtration in dairy processing?

Membrane filtration is a process that separates particles based on their size and molecular weight. In dairy processing, it is used for:

- Reverse Osmosis: Removing water from milk to concentrate solids.

- Ultrafiltration: Removing large molecules such as proteins from milk.

- Microfiltration: Removing bacteria and somatic cells from milk.

Principles of Membrane Filtration:

- Feed solution is pumped through a semi-permeable membrane.

- Small molecules pass through the membrane, while larger molecules are retained.

- Permeate (filtered liquid) is collected, while retentate (concentrate) contains larger molecules.

5. Explain the importance of casein in dairy products?

Casein is the primary protein in milk and plays a crucial role in the functionality of dairy products.

- Structure and Texture: Casein forms a network that gives dairy products their characteristic structure and firmness.

- Emulsification: Casein helps stabilize emulsions in dairy products, preventing fat separation.

- Nutritional Value: Casein is a high-quality protein, containing essential amino acids.

- Manufacturing Applications: Casein is used in the production of cheese, yogurt, caseinates, and other dairy ingredients.

6. Describe the techniques used for yogurt production?

Yogurt production involves several key steps:

- Milk Preparation: Milk is standardized for fat and protein content and heat-treated.

- Starter Culture Inoculation: Live yogurt cultures (Streptococcus thermophilus and Lactobacillus acidophilus) are added to the milk.

- Fermentation: Milk is held at a specific temperature (42-45°C) to allow bacteria to ferment lactose, producing lactic acid.

- Cooling and Storage: Fermented yogurt is cooled to stop fermentation and extend shelf life.

7. Discuss the challenges in shelf-life extension of dairy products?

8. Explain the principles of homogenization in dairy processing?

Homogenization is a mechanical process that breaks down fat globules in milk, resulting in a more uniform and stable product.

- Principles of Homogenization:

- Milk is forced through a narrow orifice under high pressure.

- Pressure disrupts fat globules, reducing their size and distributing them evenly throughout the milk.

- Homogenization improves stability, prevents creaming, and enhances mouthfeel.

9. Describe the factors influencing the choice of packaging materials for dairy products?

- Barrier Properties: Protecting products from oxygen, moisture, and light.

- Product Compatibility: Compatibility with the product’s composition and acidity.

- Shelf Life Requirements: Meeting the desired shelf life of the product.

- Environmental Considerations: Sustainability, recyclability, and biodegradability.

- Cost and Availability: Cost-effectiveness and accessibility of the packaging material.

10. Explain the role of quality control in dairy manufacturing?

Quality control is crucial in dairy manufacturing to ensure the safety and quality of dairy products.

- Raw Material Inspection: Inspecting raw milk and other ingredients for quality and compliance.

- Production Monitoring: Monitoring production processes to ensure adherence to standards.

- Product Testing: Conducting chemical, microbiological, and sensory tests to evaluate product quality.

- Corrective Actions: Identifying and implementing corrective actions to address any quality deviations.

- Documentation and Record-Keeping: Maintaining accurate records of quality control activities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dairy Technologist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dairy Technologist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dairy Technologists are responsible for ensuring the quality and safety of dairy products. They work in a variety of settings, including dairy farms, processing plants, and research laboratories.

1. Product Development

Dairy Technologists develop new dairy products and improve existing ones. They work with other scientists and engineers to create products that meet the needs of consumers.

- Conduct research to identify new product opportunities.

- Develop and test new product formulations.

2. Quality Control

Dairy Technologists ensure that dairy products meet quality and safety standards. They conduct tests to check for bacteria, contaminants, and other hazards.

- Develop and implement quality control procedures.

- Monitor and control production processes to ensure compliance with quality standards.

3. Research and Development

Dairy Technologists conduct research to improve the quality and safety of dairy products. They work with other scientists to develop new technologies and products.

- Conduct research to improve the efficiency of dairy production processes.

- Develop new technologies to improve the quality and safety of dairy products.

4. Technical Support

Dairy Technologists provide technical support to dairy farmers and processors. They help them to troubleshoot problems and improve their operations.

- Provide technical assistance to dairy farmers and processors.

- Train dairy farmers and processors on new technologies and products.

Interview Tips

Preparing for a Dairy Technologist interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and succinctly.

- Prepare a brief overview of your experience and qualifications.

- Think about why you are interested in the position and the company.

- Practice answering questions about your strengths and weaknesses.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Dairy Technologist. Be prepared to discuss your work experience, your education, and any relevant certifications or training.

- Highlight your experience in product development, quality control, research and development, and technical support.

- Quantify your accomplishments whenever possible.

- Be prepared to discuss your knowledge of dairy science and technology.

4. Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. It is also a good way to show the interviewer that you are interested in the job.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the position.

- Ask about the company’s plans for the future.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Dairy Technologist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.