Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dampener Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dampener Operator so you can tailor your answers to impress potential employers.

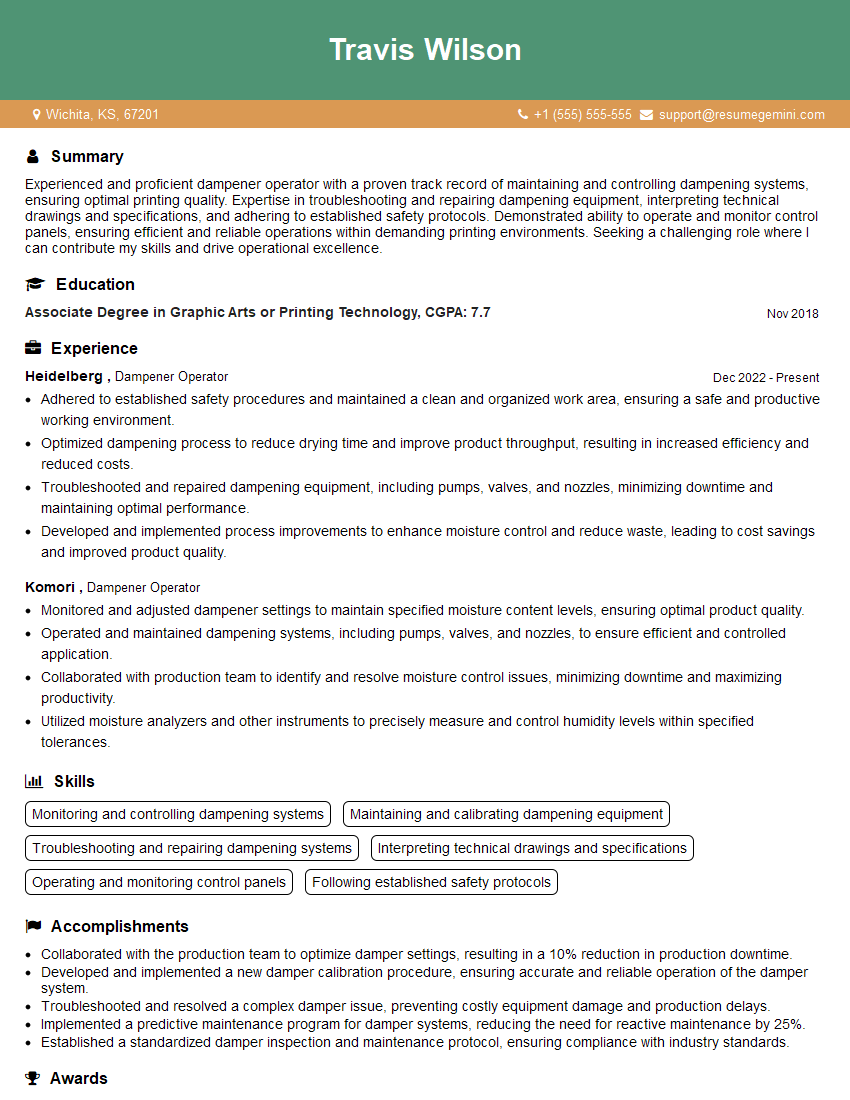

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dampener Operator

1. What are the main responsibilities of a Dampener Operator?

As a Dampener Operator, my key responsibilities typically include:

- Operating and monitoring dampening systems to ensure optimal moisture levels on printing plates

- Adjusting ink and water balance to achieve desired print quality standards

- Troubleshooting and resolving issues related to dampening systems, such as leaks, uneven wetting, or fluctuations in alcohol content

- Maintaining cleanliness and proper functionality of all dampening components and equipment

- Adhering to safety protocols and maintaining a safe working environment

2. Describe the process of setting up and calibrating a dampening system.

Setup

- Ensure proper installation of dampening rollers and associated components

- Set the correct water level and alcohol concentration in the fountain

- Adjust the pressure of the dampening rollers to achieve optimal wetting of the printing plate

Calibration

- Run test prints to assess ink and water balance on the printed image

- Make fine adjustments to the dampening system based on print results, such as adjusting the water flow or roller pressure

- Repeat test prints until desired print quality is achieved

3. How do you troubleshoot common issues that arise with dampening systems?

Common issues and troubleshooting steps include:

- Leaks: Identify the source of the leak and tighten loose connections, replace worn seals, or adjust roller pressure as needed.

- Uneven wetting: Check for damaged or misaligned dampening rollers, adjust the water flow or roller pressure, and ensure proper fountain settings.

- Fluctuations in alcohol content: Monitor the alcohol concentration regularly and adjust the fountain settings as needed to maintain the desired level.

4. What safety precautions should be taken when operating a dampening system?

Key safety precautions include:

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses

- Keeping hands and loose clothing away from moving parts of the dampening system

- Being aware of potential hazards such as slippery floors or chemical spills

- Following proper lockout/tagout procedures when performing maintenance or repairs

- Reporting any safety concerns or incidents promptly to supervisors

5. How do you maintain and clean a dampening system?

Regular maintenance and cleaning tasks include:

- Cleaning dampening rollers and other components with appropriate solvents or cleaning agents

- Inspecting and replacing worn or damaged parts, such as seals, rollers, or hoses

- Lubricating moving parts as per the manufacturer’s recommendations

- Performing regular system checks to identify potential issues early on

- Adhering to established cleaning and maintenance schedules

6. How do you ensure that the dampening system is operating at optimal efficiency?

To optimize system efficiency, I:

- Regularly monitor print quality and make adjustments as needed

- Inspect and calibrate the system to maintain optimal water and ink balance

- Identify and resolve any potential issues promptly

- Follow established maintenance and cleaning schedules

- Stay up-to-date on best practices and technological advancements related to dampening systems

7. What is the importance of maintaining proper ink and water balance in a dampening system?

Maintaining proper ink and water balance is crucial because it:

- Ensures optimal transfer of ink from the printing plate to the paper

- Prevents smudging, mottling, or other print defects

- Extends the lifespan of printing plates and other components

- Improves overall print quality and consistency

8. Describe the different types of dampening systems used in printing processes.

Common types of dampening systems include:

- Alcohol dampening: Utilizes alcohol as the primary wetting agent

- Water dampening: Uses water as the main wetting agent

- Combination dampening: Combines alcohol and water in varying proportions

- Film dampening: Employs a thin film of water applied to the printing plate

9. What are the key factors that affect the performance of a dampening system?

Performance factors include:

- Type of printing process and substrates

- Environmental conditions (e.g., temperature, humidity)

- Ink and water properties

- Condition and alignment of dampening components

- Operator skill and experience

10. How do you stay up-to-date on the latest advancements in dampening technology?

To stay current, I engage in ongoing learning through:

- Attending industry conferences and workshops

- Reading technical articles and journals

- Consulting with equipment manufacturers and industry experts

- Participating in online forums and discussion groups

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dampener Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dampener Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dampener Operators are responsible for the operation, maintenance, and repair of dampers in a variety of industrial settings, such as power plants, manufacturing facilities, and commercial buildings. They ensure that the dampers are functioning properly to control the flow of air and gases, and to maintain the required environmental conditions for the efficient operation of equipment and processes.

1. Operation of Dampers

Dampener Operators are responsible for the safe and efficient operation of all dampers within their assigned area. They must be able to understand and interpret schematics and drawings to properly identify and locate dampers.

- Operate and control dampers manually and/or automatically using control systems and actuators.

- Monitor and adjust damper positions to achieve desired airflow and temperature.

- Record and maintain logs of damper operations and maintenance activities.

2. Maintenance and Repair

Dampener Operators are also responsible for the maintenance and repair of dampers and associated equipment. They must be able to perform basic troubleshooting and repair tasks, and to identify when more specialized repairs are required.

- Inspect and clean dampers and actuators to ensure proper operation.

- Lubricate moving parts and replace worn or damaged components.

- Troubleshoot and repair minor damper and actuator malfunctions.

- Assist with major repairs and overhauls as needed.

3. Safety Compliance

Dampener Operators must comply with all applicable safety regulations and procedures. They must be aware of the potential hazards associated with their work, and to take appropriate precautions to minimize the risk of injury or damage.

- Follow established safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

- Identify and mitigate potential hazards in the work area.

- Report any unsafe conditions or practices to supervisors and maintenance personnel.

4. Communication and Teamwork

Dampener Operators must be able to effectively communicate with other members of the team, and to work as part of a team to achieve common goals. They must also be able to work independently and to take initiative.

- Communicate with supervisors, maintenance personnel, and other team members.

- Participate in team meetings and discussions.

- Share knowledge and experience with colleagues.

- Train new employees and provide guidance to less experienced colleagues.

Interview Tips

Preparing for an interview for a Dampener Operator position can be daunting, but by following these tips, candidates can increase their chances of success.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Dampener Operator position you are applying for. This will give you a better understanding of the company’s culture, values, and the specific requirements of the role. You can research the company’s website, LinkedIn page, and Glassdoor reviews to gather information.

- Highlight any relevant experience or skills that align with the company’s needs.

- Be prepared to discuss your understanding of the company’s industry and how your skills can contribute to their success.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that candidates can expect to be asked during an interview for a Dampener Operator position. By practicing answering these questions in advance, candidates can become more comfortable and confident in their responses. Some common interview questions include:

- Tell me about your experience in operating and maintaining dampers.

- Describe a time when you had to troubleshoot and repair a damper.

- What are your strengths and weaknesses as a Dampener Operator?

- Why are you interested in working for our company?

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. It is also important to arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time and that you are serious about the opportunity.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the opportunity to work for their company. Be sure to convey your passion for the role and your desire to contribute to the team. A positive attitude can make a lasting impression on the interviewer and can help you stand out from other candidates.

5. Follow Up After the Interview

After the interview, be sure to follow up with the interviewer. This shows that you are still interested in the position and that you appreciate their time. You can send a thank-you note or email within 24 hours of the interview, reiterating your interest in the position and thanking the interviewer for their time.

Next Step:

Now that you’re armed with the knowledge of Dampener Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dampener Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini