Are you gearing up for a career in Damper Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Damper Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

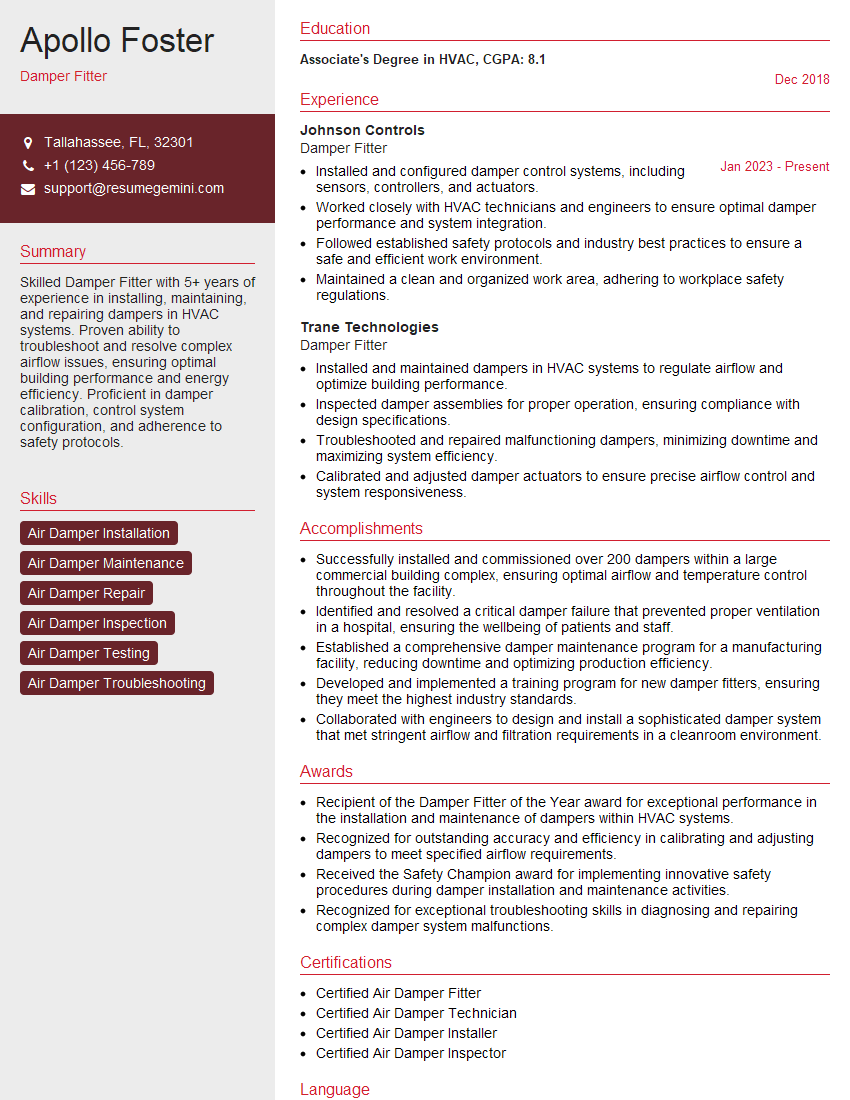

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Damper Fitter

1. What are the different types of dampers and their applications?

- Volume dampers: These dampers are used to control the airflow by adjusting the size of the opening. They are typically used in HVAC systems to regulate the airflow to different zones.

- Fire dampers: These dampers are designed to close automatically in the event of a fire to prevent the spread of smoke and fire. They are typically installed in fire-rated walls and ceilings.

- Backdraft dampers: These dampers are used to prevent backflow of air into a system. They are typically used in exhaust systems to prevent the entry of outside air.

2. What are the key factors to consider when selecting a damper?

Cost

- The cost of the damper is a key factor to consider when selecting a damper.

- The cost of the damper will vary depending on the type of damper, the size of the damper, and the materials used to construct the damper.

Size

- The size of the damper is another key factor to consider when selecting a damper.

- The size of the damper will depend on the size of the duct or opening that the damper will be installed in.

Material

- The material used to construct the damper is also a key factor to consider when selecting a damper.

- The material of the damper will determine the durability and performance of the damper.

3. What are the steps involved in installing a damper?

- Prepare the duct or opening: The first step is to prepare the duct or opening where the damper will be installed. This may involve cutting a hole in the duct or opening, or modifying the existing opening to accommodate the damper.

- Install the damper: Once the duct or opening is prepared, the damper can be installed. The damper should be installed according to the manufacturer’s instructions.

- Test the damper: Once the damper is installed, it should be tested to ensure that it is operating properly. The damper should be tested by opening and closing it several times to ensure that it is moving smoothly.

4. What are the common problems that can occur with dampers?

- Sticking dampers: Sticking dampers can be caused by a variety of factors, such as dirt and debris, corrosion, or misalignment.

- Leaking dampers: Leaking dampers can be caused by a variety of factors, such as wear and tear, damage, or improper installation.

- Noisy dampers: Noisy dampers can be caused by a variety of factors, such as vibration, improper installation, or damage.

5. How do you troubleshoot and repair a damper?

- Sticking dampers: To troubleshoot a sticking damper, first check for any dirt or debris that may be preventing the damper from moving smoothly. If there is any dirt or debris, remove it and then try to open and close the damper again.

- Leaking dampers: To troubleshoot a leaking damper, first check for any damage to the damper or the ductwork. If there is any damage, it will need to be repaired or replaced.

- Noisy dampers: To troubleshoot a noisy damper, first check for any vibration or misalignment. If there is any vibration or misalignment, it will need to be corrected.

6. What are the safety precautions that should be taken when working with dampers?

- Wear appropriate safety gear: When working with dampers, it is important to wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Be aware of your surroundings: When working with dampers, be aware of your surroundings and be careful not to trip or fall.

- Use proper tools: When working with dampers, use the proper tools for the job. Do not use tools that are not designed for working with dampers.

7. What are the latest trends in damper technology?

- Automated dampers: Automated dampers are becoming increasingly popular, as they offer a number of advantages over manual dampers.

- Energy-efficient dampers: Energy-efficient dampers are designed to reduce energy consumption by reducing air leakage.

- Smart dampers: Smart dampers are equipped with sensors that can monitor the airflow and make adjustments to the damper position accordingly.

8. What are the different types of materials used to make dampers?

- Galvanized steel: Galvanized steel is a popular material for dampers because it is strong, durable, and resistant to corrosion.

- Stainless steel: Stainless steel is another popular material for dampers because it is even more resistant to corrosion than galvanized steel.

- Plastic: Plastic dampers are lightweight and inexpensive, but they are not as durable as metal dampers.

9. What are the different types of actuators used to operate dampers?

- Manual actuators: Manual actuators are operated by hand. They are the most basic type of actuator, but they are also the least expensive.

- Electric actuators: Electric actuators are operated by an electric motor. They are more expensive than manual actuators, but they offer more control over the damper position.

- Pneumatic actuators: Pneumatic actuators are operated by compressed air. They are more expensive than electric actuators, but they are more powerful and can be used in hazardous environments.

10. What are the different types of controls used to operate dampers?

- Local controls: Local controls are mounted directly on the damper. They are the most basic type of control, but they only allow for local control of the damper.

- Remote controls: Remote controls are mounted away from the damper. They allow for remote control of the damper, which is useful for dampers that are located in difficult-to-reach areas.

- Computer controls: Computer controls allow for the most precise control of the damper. They can be used to control multiple dampers at once, and they can be programmed to operate the dampers in a specific sequence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Damper Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Damper Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Damper fitters are responsible for installing, maintaining, and repairing dampers in industrial and commercial buildings. Dampers are used to control airflow, temperature, and humidity in a wide variety of applications, from heating and cooling systems to industrial processes.

1. Installation

Damper fitters must be able to read and interpret blueprints and drawings, and they must have a good understanding of building codes and regulations.

- Follow blueprints and drawings to install dampers in the correct locations.

- Install and secure dampers using appropriate tools and techniques.

- Seal all joints and connections to ensure airtightness.

2. Maintenance

Damper fitters must be able to diagnose problems with dampers, and they must be able to make repairs or replacements as needed.

- Inspect dampers for damage, wear, or corrosion.

- Lubricate moving parts to ensure proper operation.

- Make necessary repairs or replacements to maintain optimal performance.

3. Troubleshooting

Damper fitters must be able to troubleshoot problems with dampers, and they must be able to make repairs or replacements as needed.

- Diagnose problems with dampers using a variety of tools and techniques.

- Make necessary repairs or replacements to restore proper operation.

4. Safety

Damper fitters must be aware of the safety hazards associated with their work, and they must take appropriate precautions to avoid accidents.

- Wear appropriate safety gear, including gloves, safety glasses, and hard hats.

- Follow all safety procedures and regulations.

- Lift heavy objects safely to avoid injury.

Interview Tips

Interviewing for a damper fitter position can be a daunting task, but there are a few things you can do to prepare yourself and increase your chances of success.

1. Research the company

Before the interview, take some time to research the company you are interviewing with. This will give you a better understanding of their business, their products or services, and their culture.

- Visit the company’s website.

- Read articles and news about the company.

- Look for the company on social media.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Prepare your answers to these questions in advance.

- Practice your answers out loud so that you can deliver them confidently.

3. Dress appropriately

First impressions matter, so dress appropriately for your interview. This means wearing business casual attire, such as a dress, slacks, or a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing anything too revealing or offensive.

4. Be yourself

The most important thing is to be yourself during the interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just relax, be confident, and let your personality shine through.

- Be honest in your answers.

- Be enthusiastic about the position.

- Show the interviewer that you are a hard worker.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Damper Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!