Are you gearing up for a career in Debarker Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Debarker Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

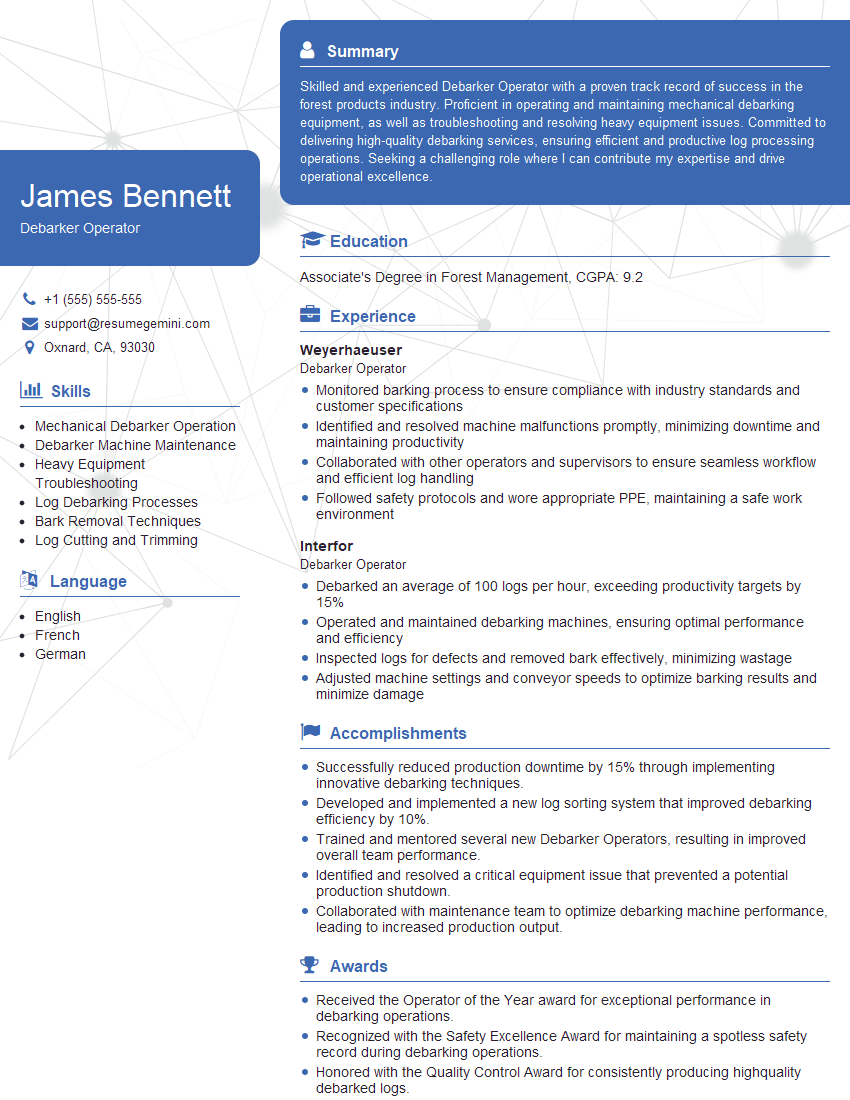

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Debarker Operator

1. Explain the process of debarking and its importance in the wood industry?

Debarking is the process of removing the outer bark from logs, which is essential for several reasons:

- Pest and disease control: Bark can harbor pests and diseases that can damage wood products.

- Preservative treatment: Debarking allows preservative treatments to penetrate the wood more effectively, enhancing its durability.

- Improved product quality: Removing the bark results in a smoother and more uniform surface, enhancing the appearance and quality of wood products.

- Reduced waste: Debarking removes non-usable material, reducing waste and increasing the yield of usable wood.

- Improved efficiency: Debarking logs before processing makes them easier to handle and reduces wear and tear on machinery.

2. Describe the different types of debarkers and their applications?

Mechanical Debarkers

- Drum debarker: Used for small-diameter logs, rotates logs to remove bark through friction and impact.

- Ring debarker: For larger logs, uses a rotating ring with knives or teeth to scrape off bark.

- Rosserhead debarker: Employs a rotating head with flails or knives to remove bark.

Chemical Debarkers

- Acid debarker: Uses chemicals like sulfuric acid to dissolve the bark and facilitate its removal.

- Steam debarker: Steam softens the bark, making it easier to remove with water jets.

3. What factors influence the choice of debarking method?

- Log size and species: Different methods are suitable for different log sizes and wood species.

- Debarking quality requirements: Some methods provide higher-quality debarking for veneer and lumber production.

- Throughput requirements: The required speed of debarking influences the choice of machine.

- Environmental regulations: Chemical debarkers must meet environmental standards for chemical disposal.

- Economic considerations: The cost and efficiency of different methods should be evaluated.

4. How do you ensure the debarking machine is operating at optimal efficiency?

- Regular maintenance: Inspect and lubricate all moving parts, replace worn components, and tighten loose connections.

- Proper feed rate: Adjust the feed rate to match the machine’s capacity, avoiding overfeeding or underfeeding.

- Knife or tooth sharpness: Ensure knives or teeth are sharp for effective debarking.

- Debarker settings: Optimize debarker settings, such as drum speed, feed pressure, and water spray angle.

- Log orientation: Position logs correctly in the debarker to facilitate efficient bark removal.

5. What troubleshooting procedures do you follow when the debarker is not operating properly?

- Inspect for blockages: Check for any blockages in the feed system, debarking unit, or discharge chute.

- Check knife or tooth condition: Ensure knives or teeth are not worn or damaged and replace if necessary.

- Adjust debarker settings: Fine-tune feed rate, drum speed, and other settings to optimize performance.

- Verify log orientation: Correctly position logs to improve debarking efficiency.

- Check hydraulic or electrical system: Ensure there are no leaks or malfunctions in the hydraulic or electrical systems.

6. How do you prioritize maintenance tasks for the debarking machine?

- Daily checks: Perform daily inspections for loose connections, leaks, and any unusual sounds.

- Weekly maintenance: Grease moving parts, inspect knives or teeth, and check hydraulic fluid levels.

- Monthly maintenance: Conduct thorough inspections, replace worn components, and calibrate sensors.

- Annual maintenance: Schedule major overhauls, including replacing major parts and performing in-depth inspections.

- Predictive maintenance: Use vibration monitoring and other tools to identify potential problems early on.

7. Describe your experience in handling emergencies related to debarking operations?

Once, during a night shift, a hydraulic hose burst, causing a major oil leak. I immediately shut down the machine, quarantined the area, and contacted maintenance. While waiting for repairs, I used absorbent pads to contain the spill and prevent further contamination.

8. How do you minimize downtime during debarking operations?

- Preventive maintenance program: Regular maintenance helps identify and address potential issues before they cause breakdowns.

- Spare parts inventory: Maintain a stock of critical spare parts to quickly replace worn or damaged components.

- Cross-training: Train multiple operators on debarker operation and maintenance to ensure coverage in case of absences.

- Troubleshooting skills: Develop strong troubleshooting skills to diagnose and resolve issues promptly, minimizing downtime.

- Communication with maintenance team: Foster a close working relationship with the maintenance team to ensure timely repairs and support.

9. How do you ensure the safety of yourself and others when operating the debarker?

- Wear appropriate PPE: Always wear safety glasses, gloves, earplugs, and a hard hat.

- Follow lockout/tagout procedures: Lock out the machine and tag it to prevent unauthorized operation during maintenance.

- Never enter the debarking area while the machine is operating: Keep a safe distance from moving parts.

- Be aware of pinch points and rotating equipment: Pay attention to potential hazards and avoid contact.

- Report any unsafe conditions or practices immediately: Ensure a safe work environment for all.

10. What is your approach to continuous improvement in debarking operations?

- Monitor key performance indicators: Track metrics such as throughput, debarking quality, and downtime to identify areas for improvement.

- Benchmarking against industry best practices: Compare performance to other similar operations to identify potential improvement strategies.

- Encourage employee feedback: Seek input from operators and maintenance personnel who have hands-on experience with the debarker.

- Implement technology solutions: Explore automation, data analytics, and predictive maintenance tools to enhance efficiency and productivity.

- Regularly review and refine processes: Continuously evaluate and improve debarking operations based on data and feedback.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Debarker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Debarker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Debarker Operator holds a vital role in ensuring efficient and optimal operations within the sawmill. Their primary responsibilities encompass:

1. Bark Removal and Log Preparation

Efficiently operating debarking equipment to remove bark from logs prior to processing. Ensuring accurate and timely debarking to minimize production delays. Maintaining sharp cutting tools and equipment to achieve desired bark removal results.

2. Log Quality Inspection and Sorting

Inspecting logs for defects, such as knots, cracks, and decay. Sorting logs based on quality and size to optimize further processing. Identifying and setting aside logs with excessive defects or unsuitable for production.

3. Production Monitoring and Optimization

Continuously monitoring debarking operations to ensure smooth and efficient flow. Adjusting debarking settings and equipment parameters to optimize bark removal and log quality. Reporting any production issues or equipment malfunctions promptly to maintain operational efficiency.

4. Equipment Maintenance and Troubleshooting

Performing regular maintenance tasks, such as greasing, lubrication, and cleaning of debarking equipment. Inspecting equipment for potential issues and resolving minor problems. Reporting major equipment malfunctions or repairs to supervisors or maintenance personnel promptly.

Interview Tips

To ace an interview for a Debarker Operator position, it is crucial to showcase your skills, experience, and enthusiasm for the role. Here are some interview tips and strategies:

1. Research the Company and Position

Before attending the interview, thoroughly research the company and the specific Debarker Operator position. This demonstrates your genuine interest and preparation. Visit the company’s website, read industry news, and prepare questions that reflect your knowledge.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly align with the job requirements. Quantify your accomplishments using specific metrics whenever possible. For instance, mention the number of logs debarked per hour or the percentage of logs prepared within quality standards.

3. Showcase your Problem-Solving Abilities

During the interview, highlight your problem-solving skills. Provide examples of situations where you identified and resolved equipment malfunctions or production issues. Discuss how your analytical thinking and troubleshooting abilities contribute to maintaining operational efficiency.

4. Demonstrate Safety Awareness

Debarking involves working with heavy machinery. Emphasize your commitment to safety. Describe your adherence to safety protocols, such as wearing appropriate protective gear and following safety guidelines. Mention your understanding of potential hazards and your proactive approach to minimizing risks.

5. Express Enthusiasm and Eagerness

Throughout the interview, convey your enthusiasm for the role and the industry. Express your eagerness to contribute to the company’s success and your commitment to continuous learning and improvement. Showcasing your passion for debarking operations will make a positive impression on the interviewers.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Debarker Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.