Are you gearing up for a career in Deburr Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Deburr Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

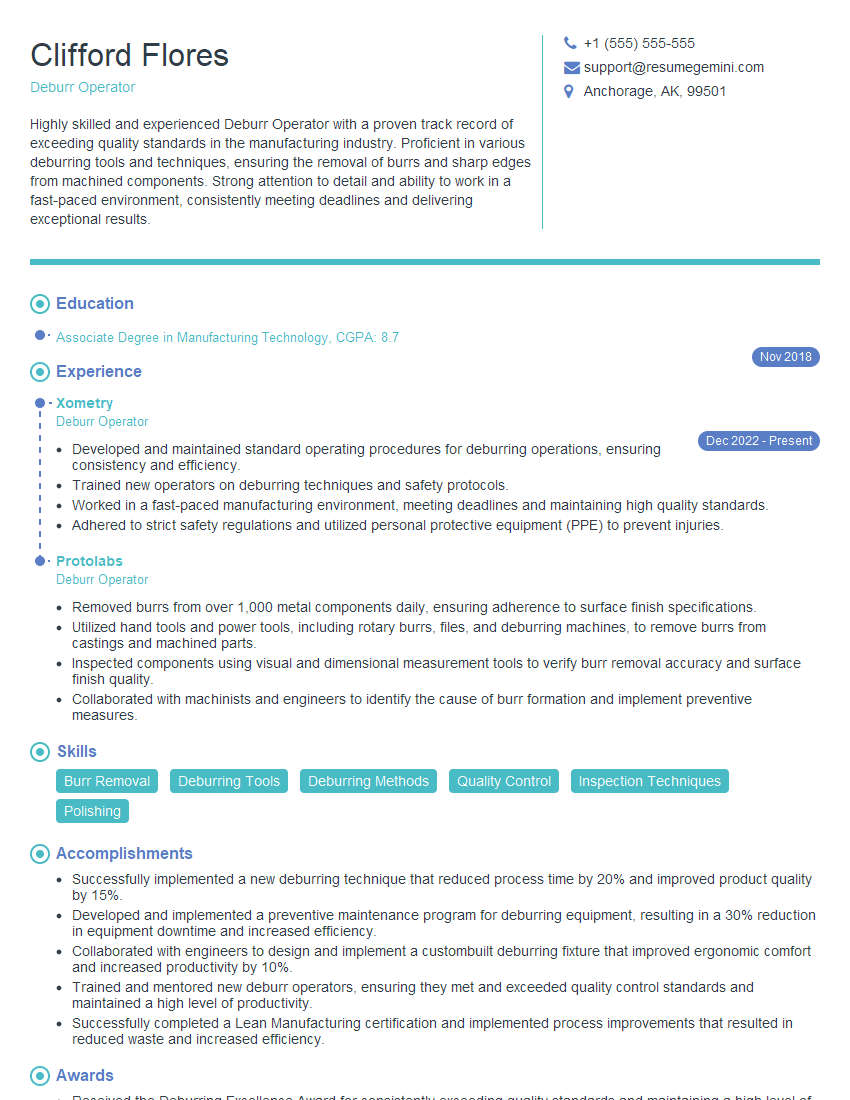

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Deburr Operator

1. Explain the process of deburring and why it is important?

Deburring is the process of removing any sharp edges or burrs from a workpiece. These burrs can be caused by a variety of machining operations, such as cutting, drilling, or grinding. Deburring is important because it can help to prevent injuries, improve the appearance of the workpiece, and extend the life of the workpiece.

2. What are the different types of deburring tools?

Manual Deburring Tools

- Hand scrapers

- Files

- Burring tools

Powered Deburring Tools

- Rotary burrs

- Belt sanders

- Wire brushes

Chemical Deburring

- Acid baths

- Electrochemical machining

3. What are the factors that affect the choice of deburring method?

- The type of material being deburred

- The size and shape of the workpiece

- The desired surface finish

- The production volume

- The cost of the deburring method

4. What are the safety precautions that should be taken when deburring?

- Wear appropriate safety gear, such as gloves, eye protection, and a respirator

- Use sharp tools that are in good condition

- Be aware of the location of your hands and fingers

- Do not deburr workpieces that are too hot or too cold

- Dispose of burrs properly

5. What are the common problems that can occur during deburring?

- Burrs that are not completely removed

- Damage to the workpiece surface

- Excessive noise and vibration

- Safety hazards

6. How can you prevent the common problems that can occur during deburring?

- Use the correct deburring method for the workpiece

- Use sharp tools that are in good condition

- Be aware of the location of your hands and fingers

- Use proper safety gear

- Dispose of burrs properly

7. What is the difference between deburring and chamfering?

- Deburring removes sharp edges from a workpiece

- Chamfering removes a small amount of material from the edge of a workpiece, creating a bevel

8. What are the benefits of deburring?

- Prevents injuries

- Improves the appearance of the workpiece

- Extends the life of the workpiece

- Reduces noise and vibration

- Improves the performance of the workpiece

9. What are the different types of burrs?

- Feather burrs

- Rollover burrs

- Sliver burrs

- Tear burrs

- Crush burrs

10. Which factors influence the formation of burrs?

- Material properties

- Tool geometry

- Cutting conditions

- Workpiece geometry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Deburr Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Deburr Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Deburr Operator is responsible for removing burrs, sharp edges, and small imperfections from manufactured parts using specialized tools and techniques. Key job responsibilities include:

1. Removing Burrs and Imperfections

Using hand tools such as files, scrapers, and deburring wheels to remove burrs, sharp edges, and other imperfections from metal, plastic, and other materials.

2. Quality Inspection

Inspecting parts to ensure that they meet specified quality standards, including dimensional accuracy, surface finish, and absence of defects.

3. Tool Maintenance

Maintaining and sharpening tools and equipment used in the deburring process to ensure optimal performance.

4. Process Optimization

Identifying and implementing ways to improve the efficiency and effectiveness of the deburring process.

Interview Tips

To prepare for a Deburr Operator interview, consider the following tips:

1. Research the Company and Position

Learn about the company’s history, industry, products, and specific requirements for the Deburr Operator position.

2. Highlight Relevant Skills and Experience

Emphasize your experience in using deburring tools, inspecting parts, and maintaining equipment. Quantify your accomplishments whenever possible.

3. Practice Answering Common Interview Questions

Prepare for questions about your technical skills, quality control procedures, and ability to work in a fast-paced environment.

4. Prepare Questions for the Interviewer

Show interest and engagement by asking informed questions about the company, the job responsibilities, and opportunities for growth.

5. Dress Professionally and Arrive on Time

Make a positive impression by dressing appropriately and arriving on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Deburr Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!