Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Deburring Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Deburring Technician so you can tailor your answers to impress potential employers.

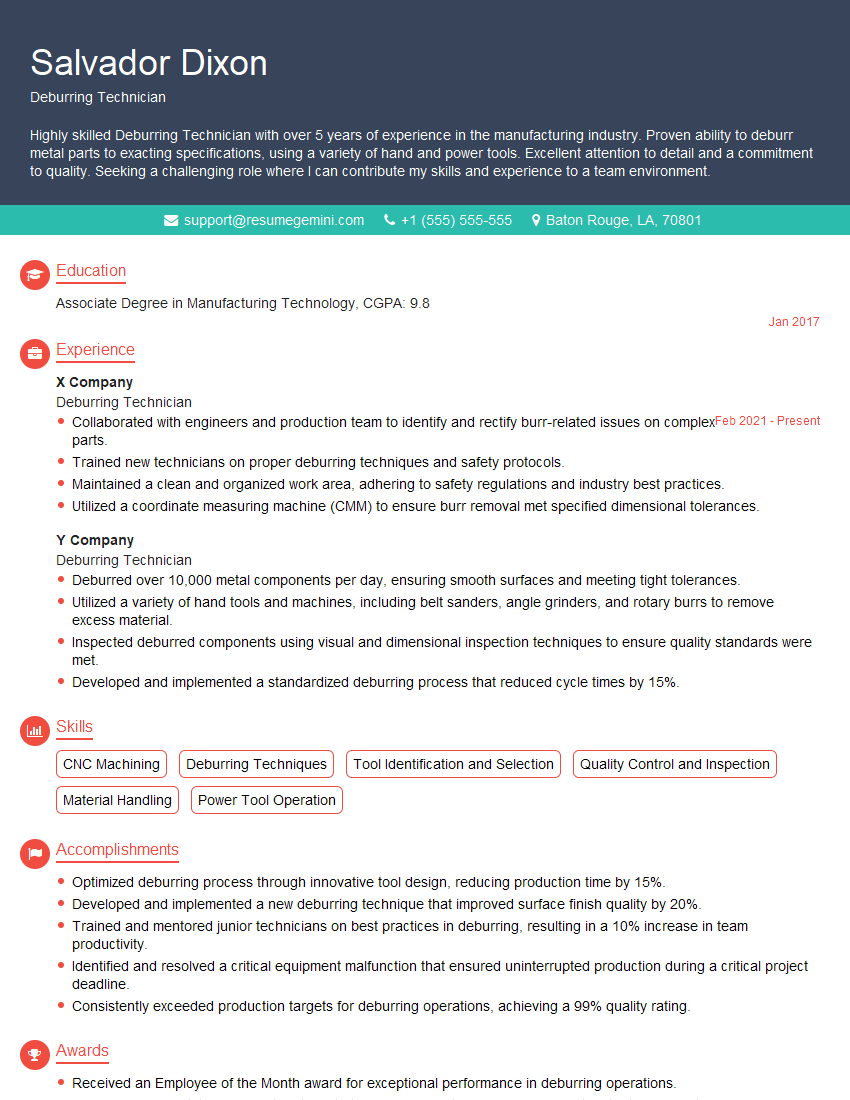

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Deburring Technician

1. What are the different types of deburring tools and their applications?

There are various types of deburring tools, each designed for specific applications. Here are some common types:

- Manual deburring tools: Hand-held tools such as scrapers, files, and brushes used for small-scale and delicate deburring tasks.

- Power deburring tools: Machine-driven tools, including rotary burrs, deburring wheels, and abrasive belts, provide higher productivity and efficiency for larger-scale deburring.

- Chemical deburring: A process that dissolves burrs using chemical agents, suitable for complex or hard-to-reach areas.

- Electrochemical deburring: An electrochemical process that removes burrs through controlled electrolysis, offering precision and minimal material loss.

2. How do you select the appropriate deburring method for a given material and application?

Factors to Consider:

- Material characteristics: Hardness, strength, and composition of the workpiece.

- Burr size and location: Thickness, height, and accessibility of the burrs.

- Surface finish requirements: Desired surface quality and roughness.

- Volume and production rate: Number of parts to be deburred and required efficiency.

- Cost and availability: Budget and availability of deburring tools and equipment.

Selection Process:

- Evaluate the material and burr characteristics.

- Consider the surface finish requirements and production volume.

- Research and compare different deburring methods based on these factors.

- Select the method that provides the best combination of effectiveness, efficiency, and cost.

3. Describe the process of deburring a cast aluminum part.

Deburring a cast aluminum part involves the following steps:

- Inspection: Examine the part to identify the location and severity of burrs.

- Safety: Wear appropriate PPE, including gloves, safety glasses, and a respirator if necessary.

- Deburring: Select the appropriate deburring tool based on the part geometry and burr characteristics. Manually or mechanically remove burrs, taking care not to damage the surface.

- Cleaning: Remove any debris or swarf created during deburring using compressed air, a brush, or a solvent.

- Inspection: Verify that all burrs have been removed and the surface is free of defects.

4. What are some common defects that can occur during deburring and how can they be prevented?

Common defects during deburring include:

- Surface scratches: Caused by using abrasive tools with too much force or an inappropriate grit size.

- Edge rounding: Removing too much material, resulting in rounded edges instead of sharp corners.

- Material damage: Using excessive force or improper tools can gouge or deform the workpiece surface.

- Incomplete deburring: Failing to remove all burrs, leaving sharp edges or potential hazards.

Prevention measures include:

- Selecting the appropriate tool for the job.

- Using proper technique and applying the correct force.

- Regularly inspecting and maintaining deburring tools.

- Establishing clear deburring specifications and quality control processes.

5. How do you ensure the quality of your deburring work?

To ensure the quality of deburring work:

- Visual inspection: Examine the deburred parts for any remaining burrs, surface defects, or damage.

- Dimensional inspection: Use measuring tools to verify that the dimensions and shape of the part meet specifications.

- Surface finish testing: Measure the surface roughness and texture to ensure compliance with requirements.

- Functional testing: Test the part’s functionality to verify that deburring has not compromised its performance.

6. What are some innovative techniques or technologies used in deburring?

Innovative deburring techniques and technologies include:

- Laser deburring: A non-contact method that uses a laser beam to vaporize burrs precisely.

- Waterjet deburring: A high-pressure water jet removes burrs while minimizing surface damage.

- Cryogenic deburring: A process that freezes the workpiece and then uses a cold blast to embrittle and remove burrs.

- Automated deburring systems: Robotic systems that perform deburring operations with high precision and consistency.

7. What are the safety considerations when performing deburring operations?

Safety considerations for deburring include:

- Sharp edges: Wear cut-resistant gloves and avoid touching burrs directly.

- Dust and swarf: Use a respirator and proper ventilation to prevent inhalation of harmful particles.

- Machinery hazards: Follow proper operating procedures and safety protocols when using power deburring tools.

- Electrical hazards: Ensure proper grounding and use insulated tools when working with electrical equipment.

- Ergonomics: Maintain proper posture and use ergonomic tools to prevent strain and injuries.

8. What is your experience with deburring composite materials?

Composite materials require specialized deburring techniques to prevent damage and maintain their structural integrity. My experience in this area includes:

- Using hand tools and abrasive wheels specifically designed for composites.

- Understanding the different types of reinforcements and their impact on deburring methods.

- Applying proper cutting angles and speeds to avoid delamination or fiber pull-out.

- Ensuring that the surface finish meets the required specifications for composite applications.

9. How do you handle deburring in a high-volume production environment?

In a high-volume production environment, efficiency and quality control are crucial. My approach includes:

- Process optimization: Analyzing and optimizing the deburring process to reduce cycle times and improve productivity.

- Automation: Implementing automated deburring systems or fixtures to increase efficiency and consistency.

- Quality control: Establishing rigorous inspection procedures to ensure that all parts meet the required specifications.

- Preventive maintenance: Regularly servicing and maintaining deburring equipment to minimize downtime and ensure optimal performance.

10. What recent advancements in deburring technology have you followed?

I stay updated on the latest advancements in deburring technology through industry publications, conferences, and online resources. Some recent developments that have caught my attention include:

- Artificial intelligence (AI) in deburring: AI algorithms can analyze part geometries and optimize deburring parameters for improved efficiency and quality.

- Ultrasonic-assisted deburring: Using ultrasonic vibrations to enhance the removal of burrs while reducing surface damage.

- Environmentally friendly deburring methods: Exploring alternative techniques that minimize waste and environmental impact, such as waterjet deburring.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Deburring Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Deburring Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Deburring Technician plays a crucial role in ensuring the quality and precision of manufactured products. Their primary responsibility is to remove burrs, sharp edges, and rough surfaces from metal parts using specialized tools and techniques.

1. Deburring and Finishing

The core responsibility of a Deburring Technician is to deburr metal components. This involves removing excess material, sharp edges, and imperfections from the surfaces of parts using tools such as files, scrapers, and rotary brushes.

- Identify and remove burrs and sharp edges with precision and accuracy.

- Use appropriate deburring tools and techniques to achieve desired surface finishes.

2. Inspection and Quality Control

Deburring Technicians are also responsible for inspecting finished parts to ensure they meet quality standards. This involves visually examining surfaces for defects and using measuring instruments to verify dimensions.

- Conduct visual and dimensional inspections to ensure parts meet specifications.

- Maintain quality records and report any discrepancies or defects.

3. Tool Maintenance and Calibration

Deburring Technicians are expected to maintain and calibrate their tools regularly. This involves cleaning, sharpening, and adjusting tools to ensure they are functioning optimally.

- Clean, sharpen, and calibrate deburring tools to maintain precision.

- Follow established maintenance schedules and ensure tools are in good working condition.

4. Health and Safety Compliance

Deburring Technicians must adhere to safety regulations and wear appropriate protective gear during their work. They must also follow established safety protocols to minimize risks and ensure their own well-being.

- Wear personal protective equipment such as gloves, eye protection, and hearing protection.

- Follow safety protocols and maintain a clean and organized work environment.

Interview Tips

Preparing thoroughly for an interview as a Deburring Technician is crucial to showcase your skills and make a positive impression.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website and LinkedIn page to learn about their industry, products, and recent developments.

- Study the job description carefully and identify the key responsibilities and qualifications required for the position.

2. Highlight Relevant Skills and Experience

In your interview, make sure to emphasize your relevant skills and experience related to deburring and finishing. Use specific examples to demonstrate your abilities and how they align with the job requirements.

- Describe your experience in using various deburring tools and techniques.

- Share examples of how you have successfully inspected parts and maintained quality standards.

3. Emphasize Safety and Attention to Detail

Safety and attention to detail are essential qualities for a Deburring Technician. During the interview, highlight your commitment to safety and your ability to work meticulously and accurately.

- Describe your understanding of safety regulations and how you apply them in your work.

- Use examples to demonstrate your attention to detail and ability to identify and correct errors.

4. Be Prepared to Ask Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions related to the company, the position, and the industry to demonstrate your enthusiasm and desire to learn more.

- Inquire about the company’s growth plans and how the position fits into those plans.

- Ask about opportunities for professional development and advancement.

5. Dress Professionally and Arrive on Time

First impressions matter in any interview. Dress professionally and arrive on time to show respect for the interviewer and the company. Maintain good posture, make eye contact, and speak clearly and confidently.

- Choose clothing that is appropriate for a manufacturing environment, such as closed-toe shoes and comfortable work attire.

- Plan your route and allow ample time to arrive at the interview location on time or early.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Deburring Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Deburring Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.