Feeling lost in a sea of interview questions? Landed that dream interview for Decating Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Decating Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

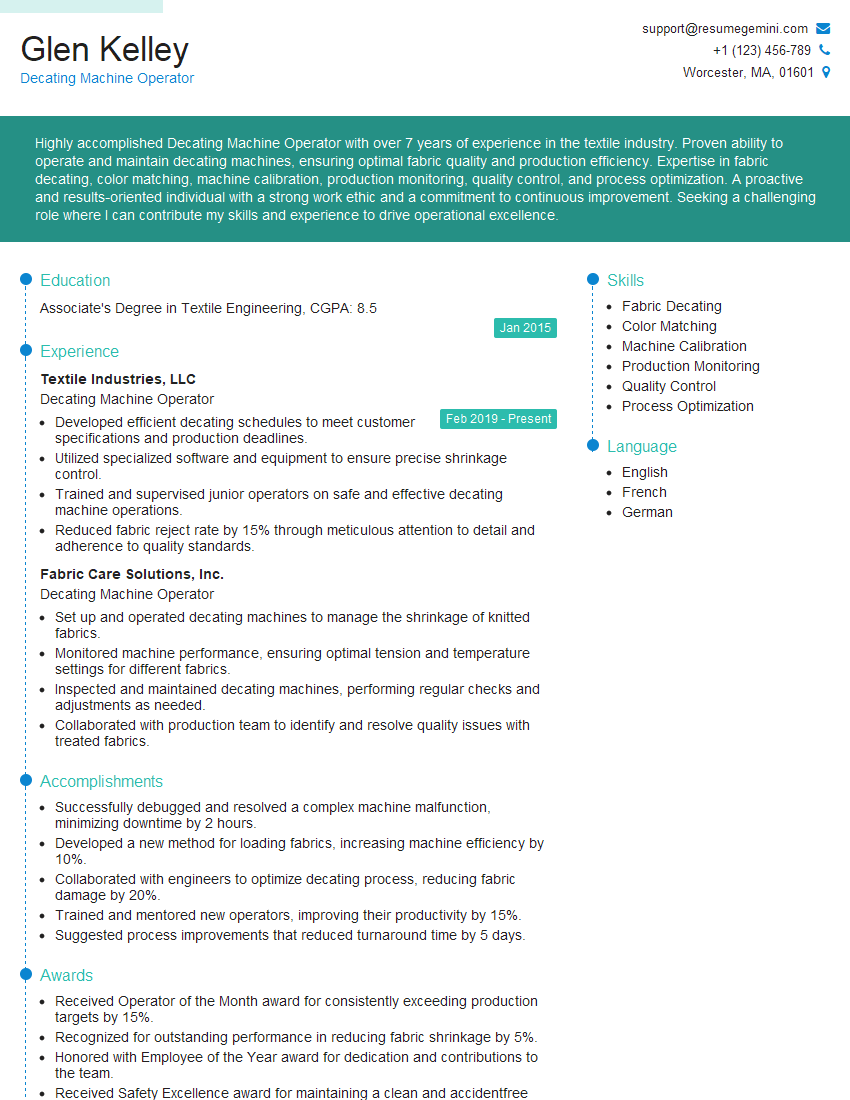

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Decating Machine Operator

1. Explain the process of decating a fabric?

The decating process involves subjecting a fabric to heat, moisture, and pressure to stabilize its dimensions and improve its handle and appearance. It includes the following steps:

- The fabric is soaked in hot water to relax the fibers.

- It is then placed in a decating machine, which consists of a perforated drum and a steam-heated chamber.

- Steam is introduced into the chamber, which penetrates the fabric and relaxes the fibers further.

- The fabric is rotated in the drum, ensuring uniform exposure to heat and steam.

- The process continues for a predetermined period, after which the fabric is cooled down and dried.

2. What are the different types of decating machines?

There are several types of decating machines, including:

Roll-type decating machines

- These machines consist of two large rollers that press the fabric against a heated surface.

- They are used for processing delicate fabrics that require gentle handling.

Drum-type decating machines

- These machines utilize a perforated drum that rotates the fabric while it is exposed to heat and steam.

- They are suitable for processing larger volumes of fabric and can be used for a wider range of fabric types.

Beam decating machines

- These machines use a rotating beam to stretch the fabric while it is subjected to heat and steam.

- They are primarily used for processing knitted fabrics.

3. What are the key parameters that need to be controlled during decating?

- Temperature: The temperature of the steam and the heated surface must be carefully controlled to ensure proper relaxation of the fibers without damaging the fabric.

- Moisture: Adequate moisture is essential for the decating process to be effective. The amount of steam introduced into the machine must be controlled to prevent over-wetting or under-wetting of the fabric.

- Pressure: The pressure applied by the rollers or the drum during decating must be sufficient to ensure uniform penetration of heat and steam into the fabric.

- Time: The duration of the decating process must be carefully determined based on the type of fabric and the desired results.

4. What is the purpose of using decating agents during decating?

Decating agents are chemical additives that are used during the decating process to enhance its effectiveness. They serve several purposes:

- Improve the penetration of heat and steam into the fabric.

- Lubricate the fibers, reducing friction and preventing damage during the process.

- Modify the surface properties of the fabric, improving its handle and appearance.

- Reduce static electricity in the fabric.

5. How do you troubleshoot common problems encountered during decating?

Common problems encountered during decating include:

- Fabric shrinkage or distortion: This can be caused by excessive heat, pressure, or moisture during decating.

- Fabric damage: This can occur due to high temperatures, excessive pressure, or improper handling of the fabric.

- Poor handle or appearance: This can result from insufficient decating or the use of inappropriate decating agents.

- Color change: This can occur if the fabric is not properly protected from heat or if the decating agents contain harmful chemicals.

To troubleshoot these problems, it is important to:

- Check the machine settings and ensure they are correct for the type of fabric being processed.

- Inspect the fabric before and after decating to identify any damage or changes.

- Experiment with different decating agents and process parameters to find the optimal combination for the desired results.

6. How do you ensure the safety of yourself and others while operating a decating machine?

To ensure safety while operating a decating machine, it is essential:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a lab coat.

- Follow all safety protocols and guidelines established by the workplace.

- Inspect the machine regularly and report any potential hazards or malfunctions.

- Be aware of the potential for burns or other injuries and take appropriate precautions.

- Operate the machine only when properly trained and authorized.

7. How do you maintain a decating machine to ensure optimal performance?

Regular maintenance is crucial to ensure the optimal performance of a decating machine. This includes:

- Cleaning the machine thoroughly after each use to remove any fabric residues or chemicals.

- Checking and replacing worn or damaged parts, such as belts, bearings, and seals.

- Calibrating the machine to ensure accurate temperature and pressure readings.

- Lubricating moving parts to reduce friction and wear.

- Conducting regular safety inspections to identify potential hazards and ensure compliance with safety regulations.

8. What are the different types of fabrics that can be decated?

A wide range of fabrics can be decated, including:

- Natural fibers: cotton, linen, wool, and silk

- Synthetic fibers: polyester, nylon, acetate, and rayon

- Blends: combinations of natural and synthetic fibers

- Knits: knitted fabrics of various constructions

9. What are the benefits of decating fabric?

Decating provides several benefits to fabrics, such as:

- Improved dimensional stability, reducing shrinkage or distortion after washing or drying.

- Enhanced handle and drape, making the fabric softer and more pliable.

- Increased luster and appearance, giving the fabric a more polished and desirable look.

- Reduced static electricity, preventing the fabric from clinging to itself or other materials.

10. How do you determine the optimal decating parameters for a particular fabric?

Determining the optimal decating parameters for a specific fabric requires:

- Fabric testing: Conducting tests on a small sample of the fabric to determine its properties, such as shrinkage, moisture regain, and fiber composition.

- Consultation with fabric suppliers or manufacturers: Obtaining recommendations from experts who have experience with the particular fabric type.

- Trial and error: Experimenting with different combinations of heat, moisture, and pressure settings on the decating machine to find the optimal parameters that achieve the desired results.

- Documentation: Recording the optimal parameters for each fabric type for future reference and consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Decating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Decating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Decating Machine Operator is responsible for operating a decating machine, which is used to treat and condition textiles. The key responsibilities of a Decating Machine Operator include:1. Machine Operation

- Set up and operate the decating machine according to established procedures.

- Monitor the machine during operation and make adjustments as needed to ensure optimal performance.

2. Textile Handling

- Load and unload textiles onto the decating machine.

- Handle textiles with care to prevent damage.

3. Quality Control

- Inspect textiles before and after decating to ensure they meet quality standards.

- Report any defects or problems to the supervisor.

4. Maintenance

- Perform routine maintenance on the decating machine, such as cleaning, lubrication, and minor repairs.

- Report any major maintenance issues to the supervisor.

5. Safety

- Follow all safety procedures and wear appropriate personal protective equipment.

- Maintain a clean and organized work area.

Interview Tips

To prepare for an interview for a Decating Machine Operator position, candidates should:1. Research the Company and Position

- Visit the company’s website to learn about their products, services, and culture.

- Identify the specific requirements of the Decating Machine Operator position.

2. Practice Common Interview Questions

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experience.

3. Highlight Relevant Skills and Experience

- Emphasize your experience operating decating machines or similar equipment.

- Describe your knowledge of textile handling and quality control.

4. Demonstrate Safety Awareness

- Discuss your understanding of safety procedures and your commitment to following them.

- Explain how you would handle potential hazards in the workplace.

5. Ask Questions

- Prepare questions to ask the interviewer about the company, the position, and the work environment.

- Asking questions shows that you are engaged and interested in the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Decating Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.