Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Decator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

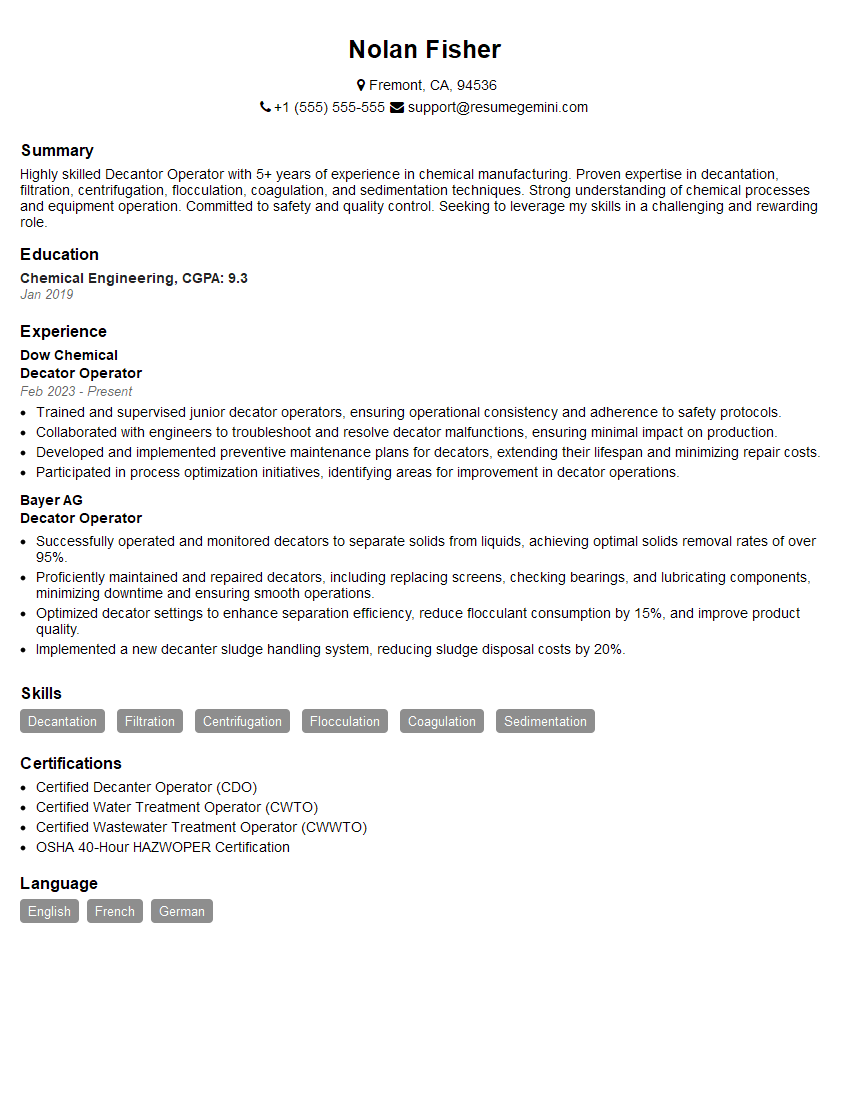

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Decator Operator

1. What are the key responsibilities of a Decator Operator?

As a Decator Operator, my primary responsibilities encompass:

- Operating and monitoring decation machines to extract oil from cottonseeds

- Maintaining and calibrating equipment to ensure optimal performance

- Enforcing safety protocols and adhering to plant regulations

- Conducting routine inspections and reporting any issues or maintenance needs

2. Describe the process of decation in detail.

Decation involves the mechanical extraction of oil from cottonseeds. The process typically involves these steps:

Pre-cleaning

- Cottonseeds are cleaned to remove impurities like dirt and debris

- This enhances the efficiency of the decation process

Delinting

- Seeds undergo a delinting process to remove short fibers (linters)

- Linters can interfere with oil extraction

Decortication

- Seeds are passed through decorticating machines to remove hulls (outer shells)

- Decortication yields meats (kernels) and hulls

Flaking

- Meats are flaked into thin sheets, increasing surface area for oil extraction

- Flaking enhances the efficiency of the extraction process

Cooking

- Flakes are cooked under controlled temperature and moisture conditions

- Cooking conditions are optimized to release oil from the flakes

Pressing

- Cooked flakes are pressed in expeller presses to separate oil from solids

- The resulting oil is collected, while the solids are processed further

Post-processing

- Extracted oil undergoes refining and purification processes to meet quality standards

- Solids are used for animal feed or other applications

3. What are the different types of decation machines?

There are various types of decation machines employed in the industry:

- Screw presses: Utilize a rotating screw to press flakes, expelling oil

- Hydraulic presses: Apply hydraulic pressure to squeeze oil from flakes

- Centrifugal extractors: Employ centrifugal force to separate oil from solids

The choice of machine depends on factors such as the type of cottonseed, desired oil quality, and capacity requirements.

4. How do you ensure the quality of the extracted oil?

Ensuring oil quality is crucial. I implement the following measures:

- Regularly monitoring process parameters (e.g., temperature, pressure) to optimize oil yield and quality

- Conducting routine oil sampling and analysis to assess purity, acidity, and other quality indicators

- Adhering to established quality standards and industry best practices

- Performing preventative maintenance and calibration of equipment to minimize contamination and maintain optimal performance

- Working closely with the quality control team to ensure compliance with specifications

5. What safety protocols are essential in a decation plant?

Safety is paramount. I prioritize these protocols:

- Wearing appropriate personal protective equipment (PPE) at all times

- Following lockout/tagout procedures during maintenance and repairs

- Maintaining a clean and organized work area to minimize hazards

- Being aware of potential hazards and taking steps to mitigate risks

- Reporting any unsafe conditions or incidents immediately to supervisors

6. How do you handle equipment breakdowns or malfunctions?

Equipment issues require prompt attention. My approach involves:

- Identifying the problem quickly and accurately through troubleshooting

- Performing necessary repairs or adjustments to restore equipment to operation

- Working with maintenance personnel if the issue requires specialized expertise

- Documenting the incident and any corrective actions taken for future reference

- Prioritizing safety throughout the troubleshooting and repair process

7. What are the key performance indicators (KPIs) used to evaluate your performance?

My performance is measured against KPIs, including:

- Oil yield and quality

- Equipment uptime and efficiency

- Production capacity

- Safety record

- Compliance with regulations

Regularly monitoring and striving to improve these KPIs ensures optimal plant performance and efficiency.

8. How do you stay updated on the latest advancements in decation technology?

Staying current with industry advancements is vital:

- Attending industry conferences and workshops to learn about new technologies

- Reading trade publications and technical journals

- Consulting with experts in the field

- Participating in online forums and discussion groups

- Exploring research and development initiatives

9. What are your strengths and weaknesses as a Decator Operator?

My strengths include:

- Expertise in decation processes and equipment

- Strong troubleshooting and problem-solving abilities

- Commitment to safety and quality

- Excellent communication and teamwork skills

- Proactive and results-oriented

Areas for improvement include:

- Expanding my knowledge of alternative oil extraction methods

- Enhancing my understanding of plant optimization techniques

10. How do you manage stress and maintain productivity in a demanding work environment?

Stress management is crucial. I employ these strategies:

- Prioritizing tasks and delegating responsibilities effectively

- Taking regular breaks and engaging in stress-reducing activities

- Communicating openly with colleagues and supervisors about workload and concerns

- Maintaining a positive attitude and focusing on solutions

- Seeking support from colleagues, mentors, or professionals if needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Decator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Decator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Decator Operators are responsible for operating and maintaining decating equipment in a variety of industries. They ensure that the equipment is running smoothly and efficiently, and that the product being produced meets quality standards.

1. Operate and Maintain Decating Equipment

Decator Operators are responsible for operating and maintaining a variety of decating equipment, including centrifuges, decanters, and filters. They must be familiar with the operation of these machines and be able to troubleshoot any problems that may arise.

- Operate centrifuges, decanters, and filters to separate solids from liquids.

- Monitor equipment operation and make adjustments as needed.

- Troubleshoot and repair equipment problems.

- Maintain equipment to ensure optimal performance.

2. Monitor Production Quality

Decator Operators are responsible for monitoring the quality of the product being produced. They must be able to identify any defects or contamination and take corrective action.

- Monitor product quality and make adjustments as needed.

- Identify and correct defects or contamination.

- Maintain production records and report any quality issues.

3. Ensure Safety and Compliance

Decator Operators must follow all safety procedures and regulations. They must also be aware of the environmental regulations that apply to their work.

- Follow all safety procedures and regulations.

- Be aware of environmental regulations and comply with them.

- Report any safety or environmental concerns.

4. Collaborate with Other Team Members

Decator Operators work closely with other team members, including engineers, production supervisors, and quality control personnel. They must be able to communicate effectively and work together to achieve common goals.

- Communicate effectively with other team members.

- Work together to achieve common goals.

- Share information and knowledge with others.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Decator Operator position:

1. Research the Company and Position

Before you go to your interview, it’s important to do your research on the company and the position you’re applying for. This will help you understand the company’s culture, values, and goals, and it will also give you a better idea of what the job entails.

- Visit the company’s website.

- Read articles about the company and industry.

- Talk to people who work for the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write down your answers to common interview questions.

- Practice saying your answers out loud.

- Get feedback from a friend or family member.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your relevant experience and how it has prepared you for this role. Use specific examples to illustrate your skills and abilities.

- Highlight your experience operating and maintaining decating equipment.

- Talk about your experience monitoring product quality.

- Discuss your safety and compliance experience.

4. Be Enthusiastic and Professional

First impressions matter, so it’s important to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer.

- Dress professionally.

- Arrive on time.

- Be polite and respectful.

- Show enthusiasm for the position.

5. Follow Up After the Interview

After the interview, it’s important to follow up with the interviewer. Thank them for their time and reiterate your interest in the position. You can also use this opportunity to ask any questions you forgot to ask during the interview.

- Send a thank-you note to the interviewer.

- Reiterate your interest in the position.

- Ask any questions you forgot to ask during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Decator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!