Feeling lost in a sea of interview questions? Landed that dream interview for Decay Control Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Decay Control Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

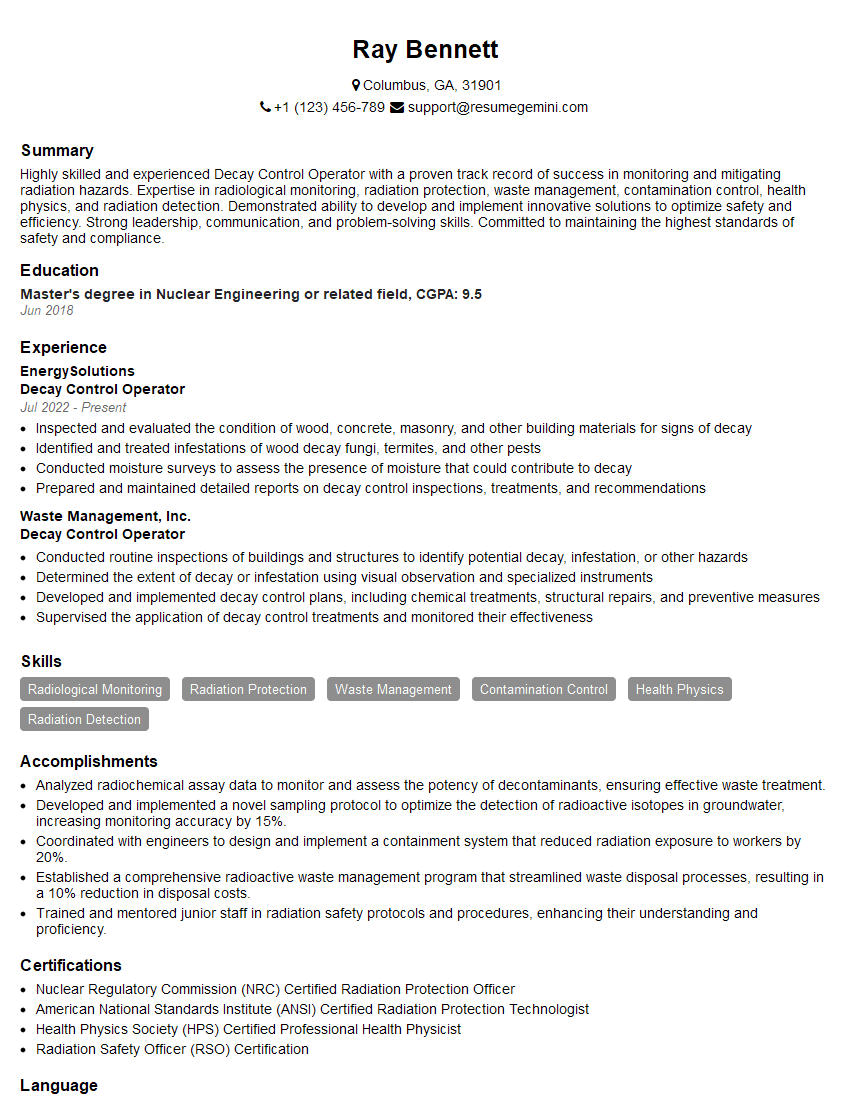

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Decay Control Operator

1. Explain the principles of wood decay and the factors that contribute to it.

- Wood decay is a complex biological process caused by various fungi that break down the structural components of wood, such as cellulose, hemicellulose, and lignin.

- Factors contributing to wood decay include moisture content, temperature, oxygen availability, wood species, and the presence of wood-decay fungi.

- High moisture content promotes fungal growth and enzymatic activity, while high temperature accelerates chemical reactions that weaken wood fibers.

- Oxygen is essential for the respiration of wood-decay fungi, and its availability influences the rate of decay.

- Different wood species have varying decay resistance depending on their physical and chemical properties.

2. Describe the different types of wood decay and their characteristics.

Brown rot

- Brown rot fungi primarily degrade cellulose, leaving behind a brown, crumbly residue.

- They cause substantial weight loss and weaken the wood’s structural integrity.

White rot

- White rot fungi break down both cellulose and lignin, resulting in a bleached or white appearance of the wood.

- They cause less weight loss than brown rot fungi but can significantly reduce wood strength.

Soft rot

- Soft rot fungi primarily attack the lignin in wood, causing a localized softening and discoloration.

- They are commonly found in waterlogged or high-moisture environments.

3. Explain the methods used to prevent and control wood decay.

- Moisture control: Reducing moisture content through proper ventilation, drainage, and protective coatings inhibits fungal growth.

- Chemical treatments: Applying fungicides or preservatives to wood surfaces protects against fungal attack.

- Physical barriers: Installing physical barriers such as moisture-resistant membranes or coatings prevents moisture penetration and fungal colonization.

- Wood selection: Using decay-resistant wood species or wood that has been treated with preservatives reduces the risk of decay.

- Regular inspections and maintenance: Periodic inspections and prompt repairs of damaged areas help prevent decay from spreading.

4. Describe the role of moisture management in preventing wood decay.

- High moisture content is a primary factor contributing to wood decay.

- Moisture management aims to keep wood dry and below the critical moisture level (typically around 20%) that supports fungal growth.

- Methods include:

- Proper ventilation to remove excess moisture from the air.

- Adequate drainage around buildings and structures to prevent water accumulation.

- Using moisture-resistant materials and coatings to prevent moisture penetration.

- Regular monitoring of moisture levels using moisture meters.

5. Explain the importance of proper ventilation in wood decay control.

- Proper ventilation helps remove excess moisture from the air, reducing the likelihood of condensation on wood surfaces.

- It prevents moisture accumulation in enclosed spaces, which can create a conducive environment for fungal growth.

- Ventilation also helps dissipate heat, which can slow down the growth of wood-decay fungi.

- Sufficient airflow allows wood to dry out more quickly after getting wet, reducing the risk of decay.

6. Describe the different types of wood preservatives and their applications.

- Oil-based preservatives: They penetrate deep into the wood and provide long-lasting protection against decay and insects.

- Water-based preservatives: They are less toxic and easier to apply but offer less durability compared to oil-based preservatives.

- Copper-based preservatives: They are effective against a wide range of wood-decay fungi and insects but can be corrosive to metal.

- Boron-based preservatives: They are non-toxic and environmentally friendly but less effective against certain types of decay fungi.

7. Explain the methods used to apply wood preservatives.

- Brushing or rolling: Preservatives are applied to the surface of the wood using a brush or roller.

- Spraying: Preservatives are sprayed onto the wood surface, ensuring even coverage.

- Dipping: Wood is submerged in a preservative solution, allowing for deep penetration.

- Pressure treatment: Wood is placed in a pressure vessel and subjected to high-pressure preservative solution, resulting in thorough impregnation.

8. Describe the safety precautions that should be followed when handling wood preservatives.

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator.

- Ensure proper ventilation in the work area to avoid inhaling fumes.

- Avoid skin contact with preservatives and clean up any spills immediately.

- Follow the manufacturer’s instructions for safe handling and disposal of preservatives.

- Store preservatives in a well-ventilated area away from heat sources.

9. Explain the importance of regular inspections and maintenance in wood decay control.

- Regular inspections allow for early detection of decay and prompt repair, preventing further damage.

- Maintenance includes cleaning gutters and downspouts to prevent water accumulation, repairing leaks, and replacing damaged wood promptly.

- Visual inspections should focus on areas prone to moisture, such as window sills, door frames, and areas in contact with the ground.

- Moisture meters can be used to detect hidden moisture that may not be visible during visual inspections.

10. Describe the environmental impact of wood decay and the importance of sustainable wood management practices.

- Wood decay can lead to the release of carbon dioxide into the atmosphere, contributing to climate change.

- Sustainable wood management practices, such as selective harvesting and reforestation, help preserve forests and reduce the environmental impact of wood decay.

- Using decay-resistant wood species and implementing proper moisture management techniques can extend the lifespan of wood products, reducing the need for replacement and minimizing environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Decay Control Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Decay Control Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Decay Control Operators are responsible for maintaining and controlling the decay process in a variety of settings, including hospitals, food processing plants, and waste treatment facilities. Their primary objective is to prevent the spread of harmful bacteria and other microorganisms that can cause disease or contamination.

1. Monitor and Assess Decay

Decay Control Operators regularly monitor and assess the decay process in their work environment. They use various techniques, such as visual inspections, temperature monitoring, and chemical testing, to determine the extent and severity of decay.

- Conduct visual inspections of surfaces, equipment, and materials for signs of decay, such as discoloration, mold growth, or odors.

- Measure temperature and humidity levels to determine if they are within acceptable ranges for decay control.

2. Implement and Maintain Control Measures

Based on their assessment of decay, Decay Control Operators implement and maintain appropriate control measures to prevent or slow its progression. These measures may include:

- Cleaning and disinfecting surfaces and equipment to remove microorganisms and prevent their spread.

- Controlling temperature and humidity levels to create an environment that is less conducive to decay.

3. Adhere to Regulatory Standards

Decay Control Operators are required to adhere to strict regulatory standards and guidelines to ensure the safety and effectiveness of their work. These standards may vary depending on the industry and setting in which they are employed.

- Follow established protocols for cleaning, disinfection, and waste disposal.

- Maintain accurate records of all decay control activities and inspections.

4. Train and Supervise Staff

In some cases, Decay Control Operators may be responsible for training and supervising staff on proper decay control practices. This may include providing instruction on cleaning and disinfection procedures, waste handling techniques, and regulatory compliance.

- Develop and implement training programs for new and existing staff.

- Provide ongoing supervision and support to ensure that staff is following proper decay control protocols.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Decay Control Operator interview:

1. Research the Company and Position

Take the time to research the company you are applying to and the specific role you are interviewing for. This will help you understand the company’s culture, values, and the specific skills and experience they are looking for in a Decay Control Operator.

- Visit the company’s website and social media pages to learn about their mission, products or services, and recent news.

- Read the job description carefully and identify the key responsibilities and qualifications required for the position.

2. Highlight Your Experience and Skills

During the interview, be sure to highlight your relevant experience and skills that align with the job requirements. Use specific examples to demonstrate how you have successfully implemented decay control measures in previous roles.

- Provide examples of successful decay control projects you have worked on in the past.

- Describe your experience with specific decay control techniques and equipment.

- Discuss your knowledge of regulatory standards and guidelines related to decay control.

3. Demonstrate Your Knowledge of the Industry

Decay Control Operators should have a strong understanding of the industry in which they are working. This includes knowledge of the latest technologies, best practices, and regulatory requirements.

- Keep up-to-date on the latest decay control trends and advancements.

- Attend industry conferences and workshops to expand your knowledge and network with other professionals.

- Stay informed about relevant laws and regulations that impact decay control practices.

4. Be Prepared to Answer Common Interview Questions

There are a number of common interview questions that you can expect to be asked during a Decay Control Operator interview. Some of the most common questions include:

- “Can you describe your experience with decay control?”

- “What are some of the challenges you have faced in decay control?”

- “How do you stay up-to-date on the latest decay control technologies and practices?”

- “What are your goals for this role as a Decay Control Operator?”

5. Ask Thoughtful Questions

At the end of the interview, you will likely have the opportunity to ask questions of your own. This is a great chance to show your interest in the position and the company, and to learn more about the organization’s culture and values.

- Ask questions about the company’s commitment to decay control.

- Inquire about the opportunities for professional development and advancement within the organization.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Decay Control Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.