Are you gearing up for an interview for a Decker Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Decker Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

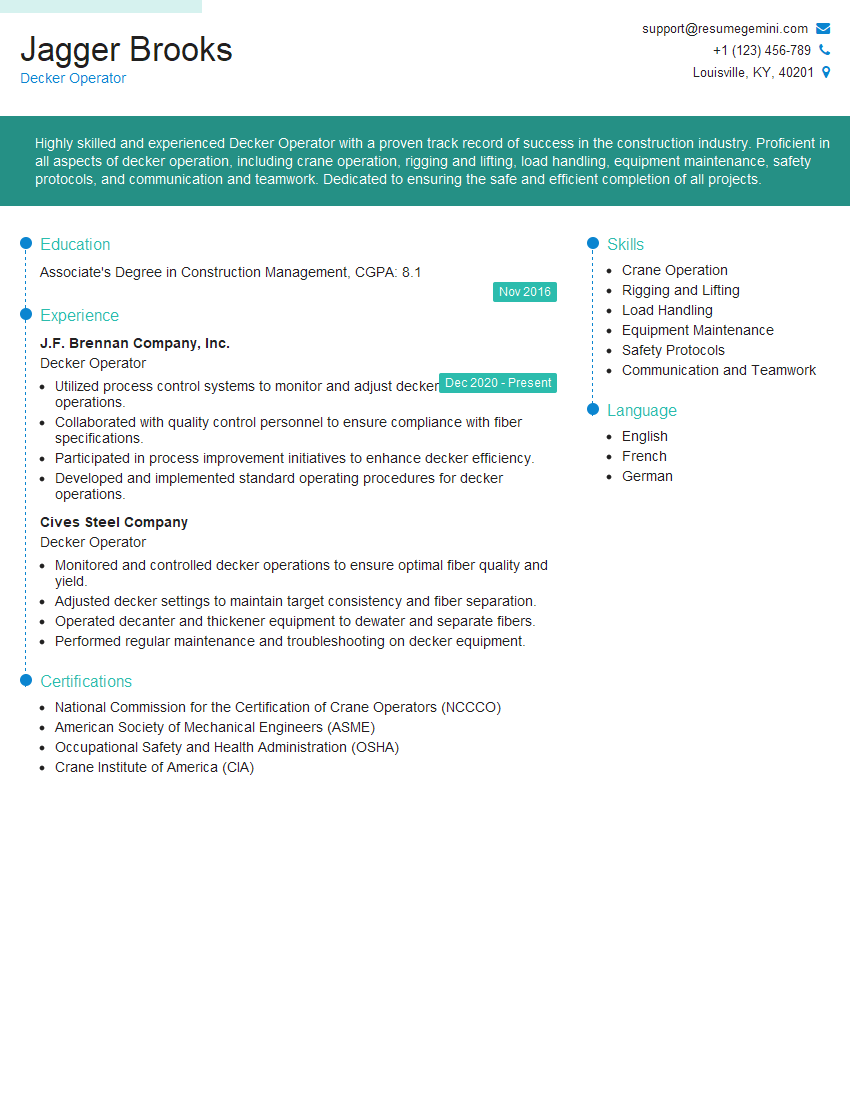

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Decker Operator

1. Describe the main responsibilities involved in performing decker operator duties?

As a Decker Operator, my primary responsibilities involve operating and maintaining decker machines to optimize wood pulp production and ensure efficient plant operations. Key tasks include:

- Operating decker machines to separate fibers from water, producing high-quality pulp

- Monitoring and adjusting machine settings to achieve optimal fiber quality and production rates

- Maintaining and troubleshooting machinery, ensuring smooth and efficient operations

- Inspecting and cleaning equipment regularly to prevent breakdowns and ensure optimal performance

- Following safety protocols and regulations to maintain a safe and productive work environment

2. How do you ensure the quality of pulp produced by the decker machine?

Monitoring and Control:

- Constantly monitoring machine parameters such as feed rate, dilution, and consistency

- Adjusting settings based on process specifications and pulp quality requirements

- Collecting and analyzing pulp samples to assess fiber size, freeness, and other quality indicators

Maintenance and Calibration:

- Regularly inspecting and calibrating equipment to ensure accuracy and reliability

- Identifying and addressing potential issues that could affect pulp quality

3. What troubleshooting techniques do you employ when encountering machine malfunctions?

Troubleshooting techniques I use to address machine malfunctions include:

- Identifying the symptoms of the malfunction (e.g., decreased production, low pulp quality)

- Reviewing operating logs and maintenance records to identify potential causes

- Conducting visual inspections to locate obvious issues (e.g., leaks, loose parts)

- Utilizing diagnostic tools and software to pinpoint electrical or mechanical faults

- Consulting with experienced colleagues or maintenance personnel for guidance and support

4. How do you prioritize maintenance tasks and ensure efficient plant operations?

I prioritize maintenance tasks based on the following factors:

- Criticality of the equipment to production

- Potential impact of the malfunction on pulp quality and plant operations

- Availability of resources (e.g., maintenance personnel, spare parts)

- Estimated time and cost of the repair

I ensure efficient plant operations by:

- Developing and adhering to a regular maintenance schedule

- Predicting potential issues through condition monitoring and proactive maintenance

- Coordinating with other departments to minimize downtime during maintenance

- Keeping detailed records of maintenance activities for future reference

5. How do you optimize production rates while maintaining pulp quality?

I optimize production rates while maintaining pulp quality by:

- Fine-tuning machine settings based on pulp specifications and production targets

- Minimizing downtime through proactive maintenance and efficient troubleshooting

- Utilizing process control systems to monitor and adjust operating conditions

- Collaborating with other departments (e.g., quality control) to ensure pulp quality meets customer requirements

6. Can you discuss your experience with process control systems used in decker operations?

I have extensive experience with the following process control systems used in decker operations:

- Distributed Control Systems (DCS)

- Programmable Logic Controllers (PLCs)

- Human-Machine Interfaces (HMIs)

Using these systems, I have been responsible for:

- Monitoring and controlling machine parameters (e.g., feed rate, consistency)

- Troubleshooting and diagnosing system malfunctions

- Implementing process optimization strategies to improve efficiency and quality

- Creating and maintaining control loops to ensure stable and predictable operations

7. What safety protocols and regulations do you follow as a decker operator?

I strictly adhere to the following safety protocols and regulations as a Decker Operator:

- Wearing appropriate personal protective equipment (PPE), including hard hats, safety glasses, gloves, and earplugs

- Following lockout/tagout procedures to prevent accidental machine startup during maintenance

- Maintaining a clean and organized work area to prevent slips and falls

- Reporting any unsafe conditions or potential hazards to supervisors immediately

- Participating in regular safety training and refresher courses to stay updated on best practices

8. How do you stay up-to-date with advancements in decker technology and best practices?

I stay up-to-date with advancements in decker technology and best practices through the following methods:

- Attending industry conferences and workshops

- Reading technical journals and publications

- Consulting with experts in the field

- Participating in online forums and discussion groups

- Seeking opportunities for professional development and training

9. What are some common challenges you have faced as a decker operator, and how did you overcome them?

One common challenge I have faced is equipment malfunctions. When this occurs, I follow a systematic troubleshooting process to identify the root cause and implement the appropriate corrective actions. I also actively collaborate with maintenance personnel to ensure timely repairs and minimize downtime.

Another challenge is maintaining consistent pulp quality. To overcome this, I constantly monitor machine parameters, analyze pulp samples, and make necessary adjustments to the process. I also work closely with the quality control department to ensure our products meet customer specifications.

10. Why are you interested in this decker operator position, and how do you see your skills and experience contributing to our team?

I am highly motivated to join your organization as a Decker Operator for the following reasons:

- The opportunity to contribute my technical skills and experience to a reputable company in the industry

- The chance to work on state-of-the-art machinery and implement innovative process improvements

- The collaborative and supportive work environment that fosters professional growth

I am confident that my strong technical expertise, commitment to safety, and eagerness to learn and contribute will make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Decker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Decker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Decker Operators play a crucial role in the construction industry, operating heavy equipment to shape and compact soil, asphalt, and other materials. To excel in this role, candidates should possess a solid understanding of the following key responsibilities:

1. Equipment Operation

Decker Operators are highly skilled in operating various types of heavy equipment, including bulldozers, graders, and compaction rollers. They are responsible for:

- Controlling equipment movement to precisely grade, level, and compact materials

- Monitoring equipment performance, identifying and addressing any issues

- Maintaining a safe working environment while operating heavy machinery

2. Surface Preparation

Decker Operators play a key role in preparing surfaces for construction projects:

- Clearing and leveling land areas, removing vegetation and debris

- Excavating and backfilling trenches for pipelines, foundations, and other structures

- Compacting soil and gravel to create stable bases for roads, parking lots, and other surfaces

3. Material Handling

Decker Operators are also responsible for handling and transporting materials on construction sites:

- Using equipment to spread and grade materials such as soil, gravel, and asphalt

- Loading and unloading materials from trucks and other vehicles

- Ensuring that materials meet specifications and are properly placed on the worksite

4. Safety and Compliance

Decker Operators prioritize safety on construction sites:

- Adhering to all safety regulations and procedures

- Inspecting equipment regularly to identify and repair any potential hazards

- Maintaining a clean and organized work area

Interview Tips

Preparing thoroughly for a Decker Operator interview is essential to make a positive impression and showcase your qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company you are applying to, as well as the specific Decker Operator role. This will give you a better understanding of the company’s culture, values, and the requirements of the position. Researching industry-specific terms and equipment will also demonstrate your enthusiasm and commitment.

2. Highlight Relevant Experience

Emphasize your previous experience operating heavy equipment, particularly in a construction setting. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact. For example, you could highlight how you increased productivity on a project by optimizing equipment usage or improved safety by implementing new protocols.

3. Demonstrate Problem-Solving Skills

Decker Operators often encounter unexpected challenges on the job. During the interview, provide examples of how you have solved problems effectively in the past. Focus on situations where you used critical thinking, communication, and teamwork to overcome obstacles.

4. Ask Thoughtful Questions

Asking well-informed questions at the end of the interview shows that you are engaged and interested in the role. Prepare questions that demonstrate your understanding of the industry and your eagerness to contribute to the company. For instance, you could ask about the company’s approach to sustainable construction or their plans for upcoming projects.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and professional demeanor. Show your enthusiasm for the role and the construction industry. Dress appropriately, be punctual, and demonstrate strong communication skills. Your attitude and demeanor can significantly influence the interviewer’s perception of your suitability for the position.

Next Step:

Now that you’re armed with the knowledge of Decker Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Decker Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini