Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Deflash and Wash Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

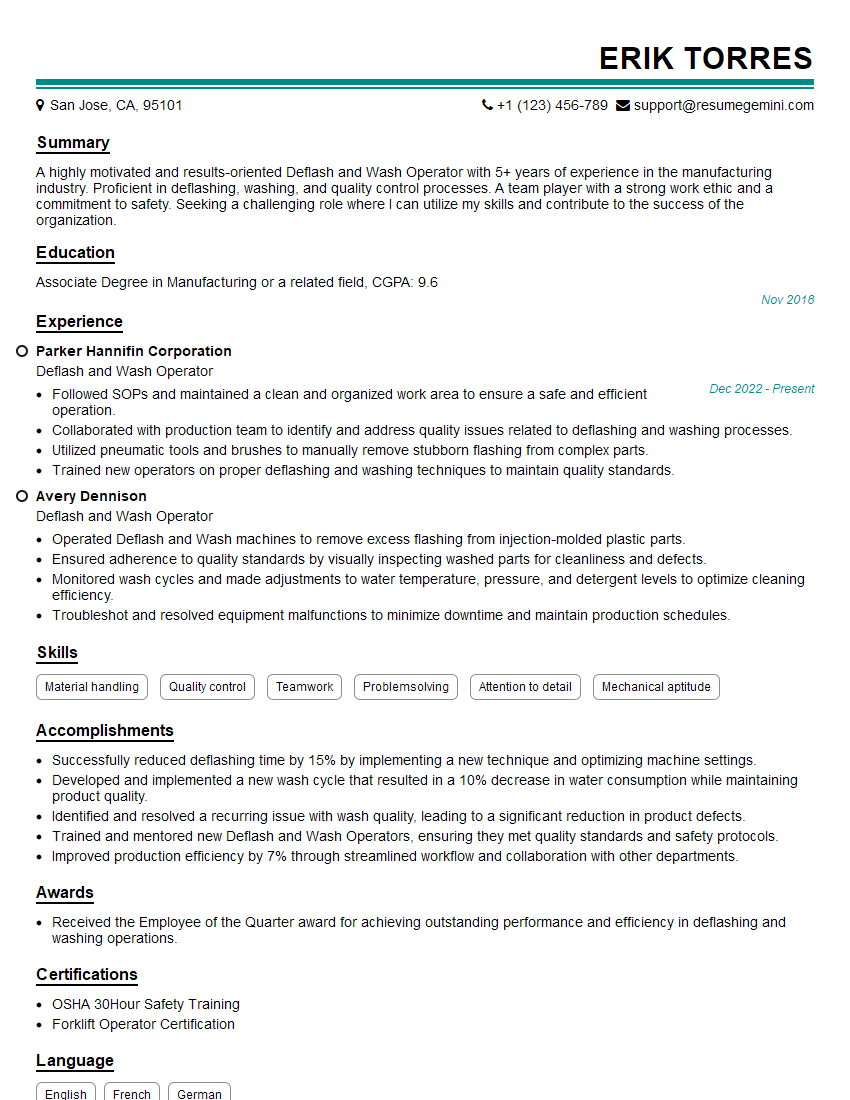

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Deflash and Wash Operator

1. Describe the process of deflashing and washing plastic parts in detail.

- First, the plastic parts are placed in a deflashing machine.

- The deflashing machine uses a rotating blade to remove any excess plastic from the parts.

- The parts are then washed in a water-based solution to remove any remaining debris.

- The parts are then dried and inspected to ensure that they meet the required quality standards.

2. What are the different types of deflashing machines?

- There are two main types of deflashing machines: mechanical and chemical.

- Mechanical deflashing machines use a rotating blade to remove excess plastic.

- Chemical deflashing machines use a chemical solution to dissolve the excess plastic.

3. What are the advantages and disadvantages of mechanical and chemical deflashing?

Advantages of mechanical deflashing:

- Faster than chemical deflashing

- More precise than chemical deflashing

- Can be used on a wider variety of materials

Disadvantages of mechanical deflashing:

- Can damage the parts if not done properly

- Can be noisy and generate dust

Advantages of chemical deflashing:

- Less likely to damage the parts

- Quieter and generates less dust than mechanical deflashing

Disadvantages of chemical deflashing:

- Slower than mechanical deflashing

- Not as precise as mechanical deflashing

- Can only be used on certain types of materials

4. What are the key factors to consider when selecting a deflashing machine?

- The type of plastic being deflashed

- The size and shape of the parts being deflashed

- The desired surface finish

- The budget

5. What are the different types of washing solutions used in deflashing and washing operations?

- Water-based solutions

- Solvent-based solutions

- Detergent-based solutions

6. What are the key factors to consider when selecting a washing solution?

- The type of plastic being washed

- The level of contamination

- The desired surface finish

- The environmental regulations

7. What are the different methods used to dry deflashed and washed parts?

- Air drying

- Heat drying

- Centrifugal drying

8. What are the key factors to consider when selecting a drying method?

- The type of plastic being dried

- The size and shape of the parts being dried

- The desired surface finish

- The throughput

9. What are the different types of inspection methods used for deflashed and washed parts?

- Visual inspection

- Dimensional inspection

- Surface finish inspection

10. What are the key factors to consider when selecting an inspection method?

- The type of plastic being inspected

- The size and shape of the parts being inspected

- The desired level of accuracy

- The throughput

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Deflash and Wash Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Deflash and Wash Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Deflash and Wash Operator plays a crucial role in ensuring the quality and cleanliness of manufactured products. Their primary responsibilities include:

1. Deflashing

Manually removing excess plastic or metal from molded or cast parts using specialized tools and techniques.

- Inspecting parts for flash and identifying areas requiring removal

- Using hand tools or automated equipment to trim and remove flash cleanly and efficiently

2. Washing

Cleaning parts thoroughly to remove dirt, debris, and contaminants.

- Soaking or spraying parts with detergents or solvents

- Using high-pressure water nozzles or ultrasonic cleaning systems to dislodge stubborn contaminants

3. Inspection

Examining parts after deflashing and washing to ensure they meet quality standards.

- Checking for any remaining flash or debris

- Identifying any surface defects or imperfections

4. Maintenance

Performing routine maintenance and cleaning on equipment used in the deflashing and washing process.

- Lubricating and adjusting tools and machinery

- Cleaning and sanitizing washing equipment to prevent contamination

Interview Tips

Preparing effectively for an interview can significantly increase your chances of success. For the Deflash and Wash Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and company culture. Understanding the industry and market trends can also demonstrate your interest and knowledge.

- Visit the company website and social media pages

- Read industry-related articles and news

2. Practice Your Responses

Prepare answers to common interview questions related to your skills, experience, and motivation. Consider using the STAR method to structure your responses:

- Situation: Briefly describe a relevant experience or situation.

- Task: Explain your role and responsibilities in the experience.

- Action: Outline the specific actions you took.

- Result: Highlight the positive outcomes or results of your actions.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experiences, such as:

- Attention to detail and quality-oriented mindset

- Proficient in using hand tools and automated equipment

- Experience in a manufacturing or production environment

- Understanding of safety protocols and quality standards

4. Demonstrate Your Enthusiasm

Show genuine interest in the role and the company. Express your enthusiasm for the industry and your eagerness to contribute to the team’s success.

- Convey your passion for quality and precision

- Ask thoughtful questions about the company and the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Deflash and Wash Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!