Are you gearing up for a career in Dehydration Plant Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dehydration Plant Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

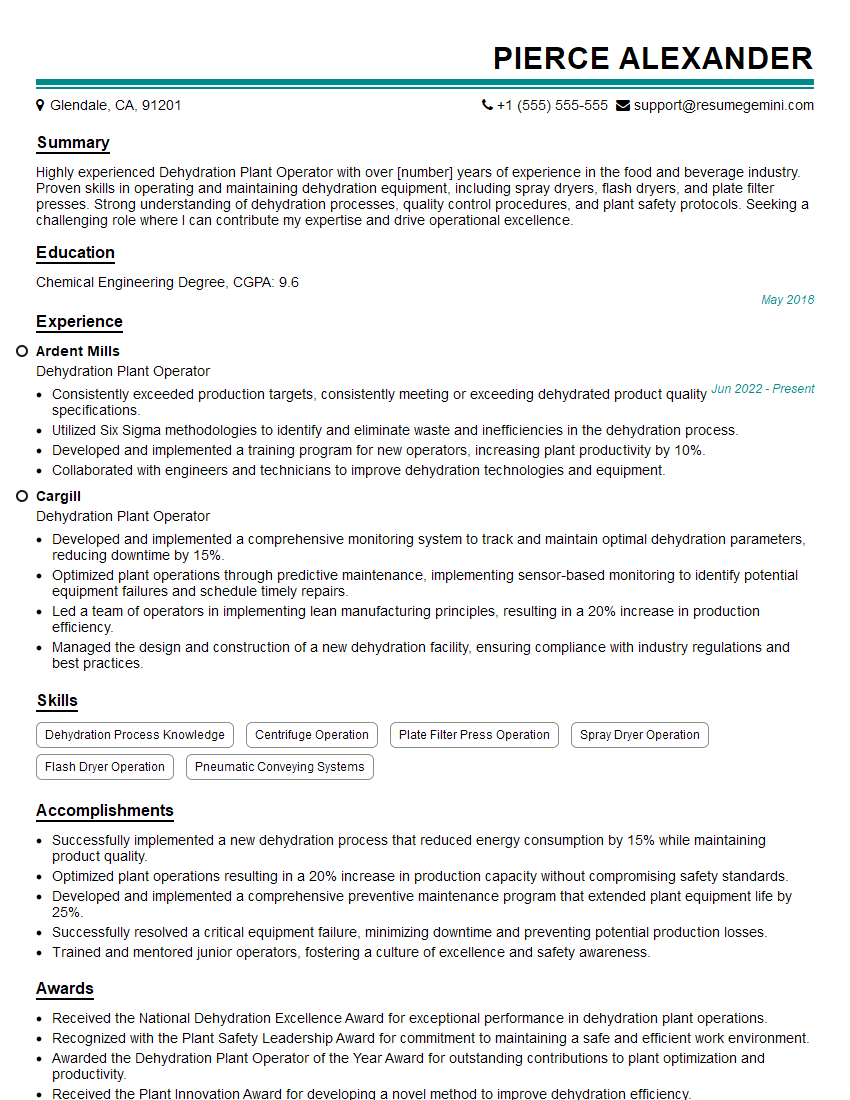

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dehydration Plant Operator

1. Explain the process of dehydration in a dehydration plant?

Dehydration in a dehydration plant involves removing moisture from agricultural products to preserve them and extend their shelf life. Here’s a simplified overview of the process:

- Pre-treatment: Products are cleaned, sorted, and prepared to remove impurities.

- Drying: Products are exposed to hot air or heated surfaces to evaporate moisture. This can be done in various ways, such as tunnel dryers, fluidized bed dryers, or vacuum dryers.

- Cooling: After drying, products are cooled to ambient temperature to prevent moisture re-absorption.

- Quality control: Dehydrated products are inspected and tested to ensure they meet moisture content specifications and other quality standards.

2. What are the key factors that affect the efficiency of a dehydration plant?

- Product characteristics: Moisture content, shape, size, and composition of the products being dehydrated.

- Equipment: Type and efficiency of drying equipment, including air flow rates, temperature control, and residence time.

- Process parameters: Drying temperature, time, and humidity levels.

- Environmental conditions: Ambient temperature and humidity can affect drying times and energy consumption.

- Operator expertise: Knowledge and experience of operators play a crucial role in optimizing the dehydration process.

3. Describe the safety procedures and regulations that you must follow while operating a dehydration plant?

Safety is paramount in a dehydration plant. I strictly adhere to the following procedures and regulations:

- Wearing appropriate personal protective equipment (PPE) such as gloves, hard hat, and safety glasses.

- Following lockout/tagout procedures when performing maintenance or repairs.

- Maintaining a clean and organized work environment free from hazards.

- Being aware of potential fire and explosion risks and knowing how to respond to emergencies.

- Complying with all applicable safety regulations and industry standards.

4. How do you ensure the quality of dehydrated products?

Ensuring the quality of dehydrated products is crucial. I follow these key practices:

- Monitoring moisture content: Regularly testing dehydrated products using moisture analyzers to ensure they meet specifications.

- Visual inspection: Examining products for any discoloration, damage, or contamination.

- Sensory evaluation: Tasting and smelling products to assess their flavor, texture, and aroma.

- Compliance with food safety standards: Adhering to HACCP principles and other regulatory requirements to ensure food safety.

- Record keeping: Maintaining accurate records of quality control measures and test results.

5. What is the importance of regular maintenance and calibration of equipment in a dehydration plant?

Regular maintenance and calibration are essential for efficient and safe operation of a dehydration plant:

- Equipment longevity: Proper maintenance extends the lifespan of equipment and reduces costly repairs.

- Accuracy and efficiency: Calibrated equipment ensures accurate measurements and optimal drying performance.

- Safety: Well-maintained equipment minimizes the risk of accidents and breakdowns.

- Product quality: Properly functioning equipment contributes to consistent and high-quality dehydrated products.

- Compliance: Regular maintenance and calibration meet industry regulations and standards.

6. How do you troubleshoot common problems that may occur in a dehydration plant?

- Insufficient drying: Check temperature settings, airflow, and product moisture content.

- Over-drying: Reduce drying time or temperature, or adjust product loading.

- Product damage: Inspect equipment for wear or damage, and review processing parameters.

- Contamination: Identify potential sources of contamination and implement corrective measures.

- Equipment failure: Follow established maintenance procedures and contact qualified technicians for repairs.

7. What measures can be taken to reduce energy consumption in a dehydration plant?

- Optimize drying parameters: Adjust temperature and airflow to minimize energy usage while maintaining product quality.

- Use energy-efficient equipment: Invest in energy-saving dryers, fans, and other equipment.

- Recover heat: Use heat exchangers to capture and reuse waste heat from the drying process.

- Insulate equipment: Minimize heat loss from dryers and other equipment.

- Implement energy monitoring systems: Track energy consumption and identify areas for improvement.

8. How do you stay up-to-date with the latest advancements in dehydration technology?

- Attend industry conferences and workshops: Network with experts and learn about new technologies.

- Read trade publications and technical articles: Stay informed about industry trends and best practices.

- Participate in continuing education programs: Enhance knowledge and skills through formal training.

- Consult with equipment manufacturers: Seek advice and recommendations from industry experts.

- Collaborate with peers: Share knowledge and experiences with other dehydration plant operators.

9. Describe your experience in managing a team of dehydration plant operators.

- Leadership: Motivated and guided a team to achieve production goals and quality standards.

- Training and development: Provided training to new employees and supported professional growth of the team.

- Communication: Effectively communicated instructions, provided feedback, and resolved issues within the team.

- Teamwork: Collaborated with team members to ensure smooth plant operations and problem-solving.

- Safety: Enforced safety protocols, conducted safety inspections, and fostered a safety-conscious work environment.

10. What are your career goals and aspirations as a Dehydration Plant Operator?

- Advancement: Seek opportunities for growth and responsibility within the dehydration industry.

- Expertise: Develop a deep understanding of dehydration processes and become a subject matter expert.

- Innovation: Explore and implement innovative techniques to improve plant efficiency and product quality.

- Sustainability: Contribute to the industry’s efforts towards sustainable and environmentally conscious dehydration practices.

- Mentorship: Share knowledge and expertise with junior operators, fostering their professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dehydration Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dehydration Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dehydration Plant Operators play a crucial role in the food processing industry. They operate and maintain dehydration equipment to remove moisture from agricultural products, extending their shelf life and enhancing their nutritional value. Essential job responsibilities include:

1. Equipment Operation and Maintenance

Performing routine inspections, maintenance, and repairs on dehydration equipment, including dryers, conveyors, and packaging machines. Ensuring equipment operates efficiently and safely.

2. Process Monitoring and Control

Monitoring and controlling process variables such as temperature, humidity, and airflow to achieve desired product quality. Adjusting equipment settings and troubleshooting any deviations from specifications.

3. Product Quality Assurance

Inspecting dehydrated products to ensure they meet quality standards, including moisture content, color, and texture. Conducting quality control tests and recording data to maintain product consistency.

4. Safety and Regulatory Compliance

Adhering to safety regulations and protocols, including wearing protective equipment and following safe work practices. Maintaining a clean and organized work environment. Complying with food safety regulations and industry best practices.

Interview Preparation Tips

Preparing for an interview for the position of Dehydration Plant Operator requires a combination of technical knowledge and soft skills. Here are some valuable tips to help candidates ace their job interview:

1. Research the Company and Industry

Demonstrate your interest and enthusiasm for the company and the dehydration industry. Research the company’s history, mission, values, and product line. Stay up-to-date with industry trends and advancements.

2. Highlight Relevant Experience and Skills

Clearly outline your previous experience in operating and maintaining dehydration equipment. Showcase your understanding of process monitoring, product quality assurance, and safety protocols. Emphasize your technical skills, such as troubleshooting, data analysis, and equipment calibration.

3. Prepare for Technical Questions

Anticipate technical questions related to dehydration processes, equipment operation, and quality control. Be prepared to discuss your knowledge of different types of dryers, process variables, and quality control procedures. Show your understanding of food safety regulations and industry best practices.

4. Practice Behavioral Questions

Practice answering behavioral interview questions using the STAR method (Situation, Task, Action, Result). Describe situations where you effectively solved problems, managed a team, or maintained a safe work environment. Highlight your ability to work independently, collaborate with others, and handle stress.

5. Be Enthusiastic and Confident

Convey your enthusiasm for the position and the industry. Demonstrate your confidence in your abilities to perform the job effectively. Be positive, articulate, and make eye contact with the interviewers. Show your passion for food processing and your commitment to delivering quality products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dehydration Plant Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.