Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dehydration Unit Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

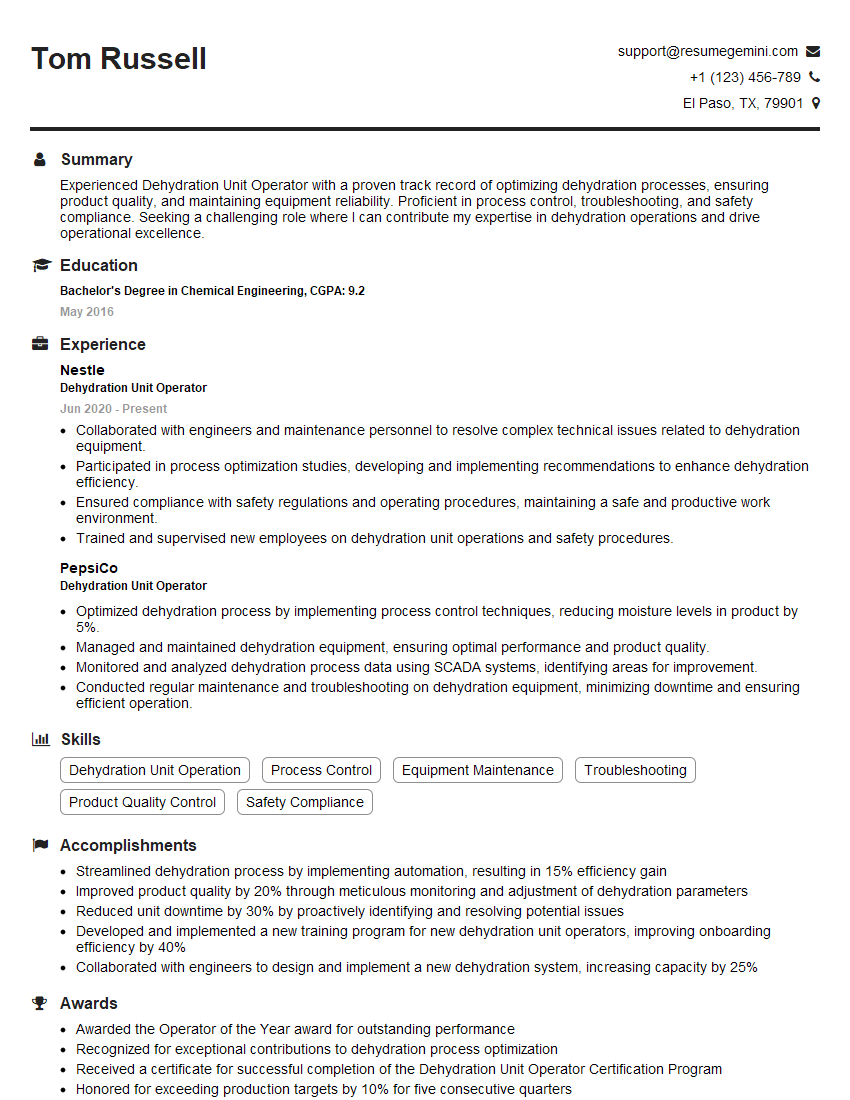

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dehydration Unit Operator

1. Describe the dehydration process and the equipment used in a dehydration unit.

In a dehydration unit, the process of dehydration involves removing water from a material, typically a food product or a chemical substance. The equipment used for this process can vary depending on the specific application and the scale of operation, but some common pieces of equipment include:

- Dryers: These can be used to remove moisture from various materials. Different types of dryers include tray dryers, fluidized bed dryers, and rotary dryers.

- Evaporators: These devices utilize heat to vaporize water from a liquid or slurry. Evaporators can be used for concentrating liquids, drying solids, and recovering solvents.

- Filters: Filters are used to separate solids from liquids and can be used to remove moisture from materials by trapping water in a filter medium.

- Centrifuges: Centrifuges use centrifugal force to separate liquids from solids. They can be used to dewater materials by removing excess liquid.

2. Explain the different types of dehydration methods used in food processing.

Air Drying

- Uses heated air to remove moisture from food.

- Can be applied to a variety of foods, including fruits, vegetables, and meat.

Freeze Drying

- Involves freezing the food and then removing the ice through sublimation.

- Preserves the food’s flavor, color, and nutritional value.

Spray Drying

- Involves atomizing a liquid food into a hot air stream.

- Produces a dry powder that is easily reconstituted.

3. Discuss the factors that affect the efficiency of a dehydration process.

The efficiency of a dehydration process can be affected by several factors, including:

- Material properties: The physical and chemical properties of the material being dehydrated, such as its moisture content, particle size, and composition, can impact the drying rate and energy consumption.

- Equipment design and operation: The type of dehydration equipment used, its design, and the operating parameters, such as temperature, airflow, and pressure, can significantly influence the efficiency of the process.

- Process conditions: The temperature, humidity, and other environmental conditions during the dehydration process can affect the drying rate and the quality of the final product.

- Scale of operation: The size and scale of the dehydration operation can also impact efficiency, with larger operations often requiring more specialized equipment and optimized processes.

4. Describe the quality control procedures used in a dehydration unit to ensure product quality.

Quality control procedures in a dehydration unit are crucial to ensure the safety and quality of the dehydrated products. These procedures may include:

- Raw material inspection: Incoming raw materials are inspected to verify their quality and suitability for dehydration.

- Process monitoring: Key process parameters, such as temperature, humidity, and drying time, are monitored and controlled to ensure optimal dehydration conditions.

- Product testing: Dehydrated products are tested to evaluate their moisture content, physical characteristics, and other quality attributes.

- Packaging and storage: Dehydrated products are packaged and stored under controlled conditions to maintain their quality and prevent spoilage.

5. Explain the safety precautions that must be observed when operating a dehydration unit.

Operating a dehydration unit requires adherence to safety precautions to minimize risks and ensure the well-being of workers. These precautions may include:

- Proper ventilation: Adequate ventilation is necessary to remove moisture and prevent condensation, which can create slippery surfaces and promote mold growth.

- Electrical safety: Electrical equipment should be properly grounded and regularly inspected to prevent electrical hazards.

- Fire prevention: Dehydration processes often involve the use of heat and flammable materials, so fire prevention measures, such as having fire extinguishers readily available, are crucial.

- Personal protective equipment (PPE): Workers should wear appropriate PPE, such as gloves, safety glasses, and respirators, to protect themselves from potential hazards.

6. Describe the maintenance procedures required for a dehydration unit.

Regular maintenance is essential to keep a dehydration unit operating efficiently and safely. Maintenance procedures may include:

- Equipment cleaning: Cleaning and sanitizing all equipment, including dryers, filters, and conveyors, is necessary to prevent contamination and maintain hygiene.

- Mechanical inspections: Regularly inspecting and servicing mechanical components, such as bearings, motors, and fans, helps to identify and address potential issues.

- Preventive maintenance: Implementing a preventive maintenance schedule, such as regular lubrication and filter replacements, can help prevent breakdowns and extend the lifespan of the equipment.

- Calibration and testing: Calibrating and testing instruments and sensors used in the dehydration process ensures their accuracy and reliability.

7. What are the challenges you have faced in operating a dehydration unit, and how did you overcome them?

In my previous role as a Dehydration Unit Operator, I encountered various challenges that required problem-solving and technical expertise:

- Equipment malfunction: I once encountered a situation where a dryer malfunctioned due to a faulty temperature sensor. I quickly identified the issue, replaced the sensor, and recalibrated the system, minimizing downtime and ensuring the unit continued operating efficiently.

- Product quality issues: On another occasion, the dehydrated product exhibited inconsistent moisture content. I analyzed the process parameters and discovered that the airflow rate was not optimized. By adjusting the airflow settings, I was able to achieve the desired moisture content and maintain product quality.

- Safety concerns: I prioritize safety in all operations. During a routine inspection, I noticed a potential electrical hazard. I promptly reported the issue and coordinated with the maintenance team to address it, preventing any accidents from occurring.

8. How do you stay up-to-date on the latest advancements in dehydration technology?

To stay abreast of the latest developments in dehydration technology, I engage in continuous learning and professional development activities:

- Industry publications: I regularly read industry magazines, journals, and technical articles to keep informed about new technologies and best practices.

- Conferences and seminars: Attending industry conferences and seminars provides opportunities to connect with experts, learn about innovative technologies, and gain insights into the latest trends.

- Online resources: I utilize online platforms and resources to access technical information, research papers, and case studies related to dehydration technology.

- Networking: I engage in professional networking with colleagues, industry professionals, and equipment manufacturers to exchange knowledge and stay informed about advancements in the field.

9. What are your career goals in the dehydration industry?

My career goal is to grow within the dehydration industry and contribute to the advancement of dehydration technology. I aspire to take on leadership roles where I can manage dehydration operations, innovate processes, and optimize production efficiency. I am also keen on exploring research and development opportunities to drive innovation and improve the quality and sustainability of dehydrated products.

10. Do you have any questions for me about the Dehydration Unit Operator position?

I am eager to learn more about the specific responsibilities and expectations of the Dehydration Unit Operator position within your organization. I am also interested in the company’s commitment to safety, quality, and innovation. Understanding these aspects will help me assess if my skills and experience align with the role and the organization’s goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dehydration Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dehydration Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dehydration Unit Operator plays a crucial role in the production of food and agricultural products by operating and maintaining dehydration equipment. Their responsibilities are essential in ensuring the quality and safety of dehydrated products.

1. Operating Dehydration Equipment

The primary responsibility of a Dehydration Unit Operator is to operate and maintain various dehydration equipment, including ovens, drying chambers, and conveyors. They ensure that these machines are running efficiently and in compliance with established operating parameters.

- Monitoring and adjusting temperature, humidity, and airflow within dehydration units.

- Loading and unloading products into and from dehydration chambers.

- Performing routine maintenance and cleaning of dehydration equipment to maintain optimal performance.

2. Monitoring Dehydration Process

Dehydration Unit Operators closely monitor the dehydration process to ensure that products are dried to the desired moisture content and quality standards. They use various instruments and techniques to assess the progress and make necessary adjustments.

- Sampling and testing products at different stages of dehydration to determine moisture levels.

- Adjusting operating parameters based on product characteristics and desired results.

- Identifying and resolving any issues that arise during the dehydration process.

3. Maintaining Quality Standards

Dehydration Unit Operators play a vital role in maintaining the quality and safety of dehydrated products. They adhere to strict quality control procedures and perform regular inspections to ensure that products meet established specifications.

- Inspecting products for defects, contamination, and off-odors.

- Maintaining sanitation and hygiene standards within the dehydration unit.

- Working closely with quality control personnel to ensure compliance with regulatory requirements.

4. Safety and Maintenance

Dehydration Unit Operators prioritize safety in their work environment and ensure the proper maintenance of equipment. They follow established safety protocols and perform regular maintenance tasks to prevent accidents and breakdowns.

- Following all safety regulations and wearing appropriate protective gear.

- Performing routine maintenance and troubleshooting of dehydration equipment.

- Maintaining a clean and organized work area.

Interview Tips

Preparing for a job interview as a Dehydration Unit Operator requires thorough research and practice. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This knowledge will help you demonstrate your understanding of the role and industry landscape.

- Visit the company’s website and read about their mission, values, and products.

- Research the specific industry sector and market trends to show your broader knowledge.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Practice delivering your answers with clarity and confidence.

- Prepare answers to questions about your experience with dehydration equipment and quality control procedures.

- Practice describing your understanding of the dehydration process and how you ensure product quality.

3. Showcase Your Safety Awareness

Emphasize your commitment to safety in the workplace. Discuss your understanding of safety protocols and your experience in maintaining a safe and clean work environment.

- Provide examples of how you have followed safety procedures and identified potential hazards.

- Explain your knowledge of emergency response procedures and your ability to handle unexpected situations.

4. Highlight Your Problem-Solving Skills

Dehydration Unit Operators often face challenges during the dehydration process. Share examples of how you have identified and resolved problems in the past.

- Describe a situation where you encountered an equipment malfunction and how you resolved it efficiently.

- Explain how you have handled variations in product quality and made adjustments to the dehydration process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dehydration Unit Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!