Are you gearing up for a career in Deicer Kit Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Deicer Kit Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

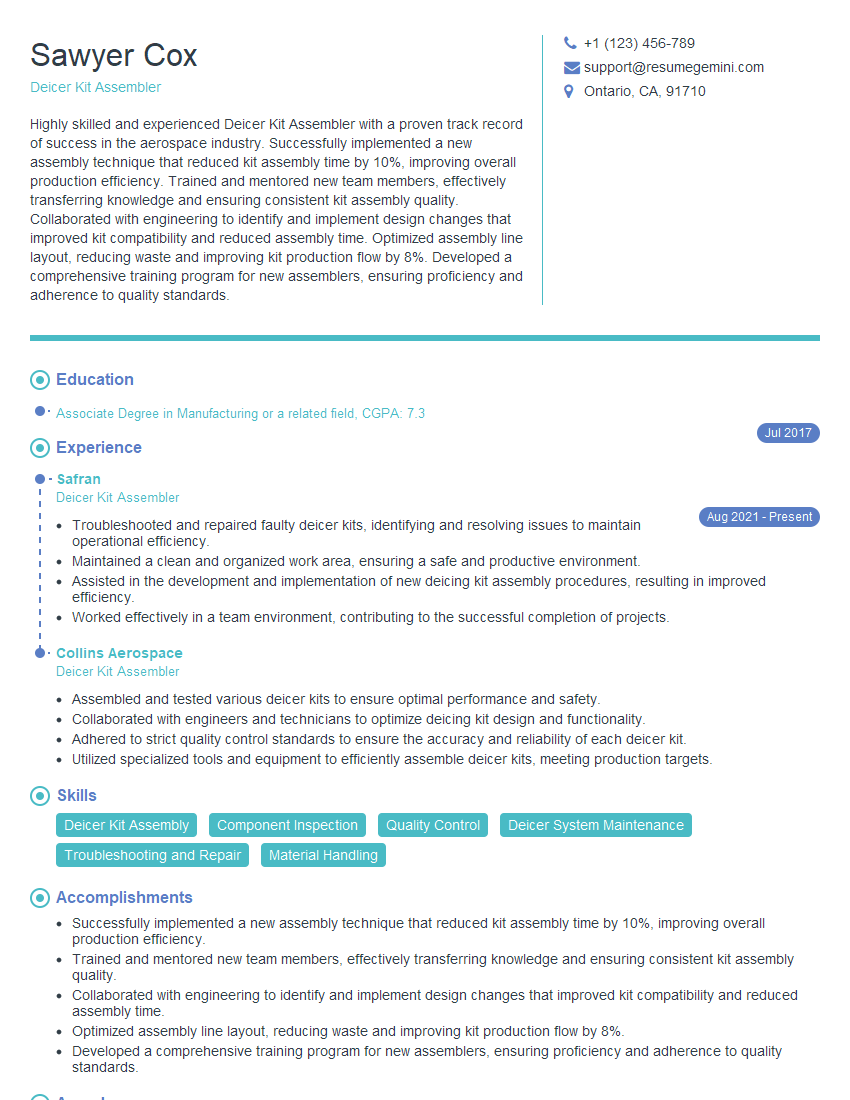

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Deicer Kit Assembler

1. Describe the primary functions and responsibilities of a Deicer Kit Assembler?

As a Deicer Kit Assembler, I would be responsible for:

- Assembling and installing deicer kits on aircraft.

- Inspecting and maintaining deicer kits to ensure they are in good working order.

- Following established procedures and meeting all safety regulations.

- Working independently and as part of a team.

2. Explain the different types of deicer kits and their applications?

There are two main types of deicer kits:

Pneumatic Deicer Boots:

- Inflatable boots that wrap around the leading edge of the wing or tail.

- When inflated, they create a turbulent airflow that breaks up ice.

- Used on large commercial aircraft and military aircraft.

Electrothermal Deicer Systems:

- Heated panels that are bonded to the leading edge of the wing or tail.

- When activated, they melt ice and snow.

- Used on smaller aircraft, such as business jets and turboprops.

3. What are the key considerations when selecting the right deicer kit for a particular aircraft?

The key considerations when selecting a deicer kit include:

- The size and type of aircraft.

- The operating environment.

- The cost and maintenance requirements.

- The aircraft’s performance requirements.

4. Describe the assembly process for a typical deicer kit?

The assembly process for a typical deicer kit involves:

- Inspecting the kit components.

- Assembling the kit according to the manufacturer’s instructions.

- Testing the kit to ensure it is working properly.

- Installing the kit on the aircraft.

5. What are the most common challenges faced by Deicer Kit Assemblers and how do you overcome them?

Some common challenges faced by Deicer Kit Assemblers include:

- Working in confined spaces.

- Handling hazardous materials.

- Meeting tight deadlines.

- Working in inclement weather.

To overcome these challenges, I rely on my training, experience, and attention to detail. I also work closely with my team to ensure that all tasks are completed safely and efficiently.

6. What are the safety precautions that must be taken when working with deicer kits?

When working with deicer kits, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Follow all manufacturer’s instructions.

- Work in a well-ventilated area.

- Avoid contact with hazardous materials.

- Be aware of the potential for electrical hazards.

7. What are the maintenance requirements for deicer kits and how often should they be inspected?

Deicer kits require regular maintenance and inspection to ensure they are in good working order. The maintenance schedule will vary depending on the type of kit and the operating environment. However, in general, deicer kits should be inspected at least annually and more frequently if they are used in harsh conditions.

8. What are the quality control procedures that are followed during the assembly and installation of deicer kits?

To ensure the quality and reliability of deicer kits, strict quality control procedures are followed during assembly and installation. These procedures include:

- Inspecting all components prior to assembly.

- Following all manufacturer’s instructions.

- Testing the kit’s functionality before installation.

- Documenting all assembly and installation steps.

9. What is your experience with troubleshooting and repairing deicer kits?

I have experience troubleshooting and repairing deicer kits on various types of aircraft. Some of the common issues I have encountered include:

- Electrical faults.

- Mechanical failures.

- Corrosion.

- Damage from foreign objects.

To troubleshoot and repair these issues, I rely on my training, experience, and the manufacturer’s documentation. I also work closely with my team to ensure that all repairs are completed safely and efficiently.

10. How do you stay up-to-date on the latest developments in aircraft deicing technology?

To stay up-to-date on the latest developments in aircraft deicing technology, I read industry publications, attend conferences, and participate in online forums. I also work closely with my colleagues and suppliers to learn about new products and technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Deicer Kit Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Deicer Kit Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Deicer Kit Assemblers play a vital role in ensuring the safe operation of aircraft during icy weather conditions. Their responsibilities involve assembling, inspecting, and testing deicer kits, which are crucial for preventing ice buildup on aircraft surfaces.

1. Assembly and Installation

Assemble and install deicer kits according to established procedures and specifications.

- Mount deicer components on aircraft surfaces, including wings, tail, and engines.

- Connect electrical, hydraulic, and pneumatic systems to ensure proper operation.

2. Inspection and Testing

Conduct thorough inspections of deicer kits after assembly and before installation.

- Examine components for damage, leaks, or loose connections.

- Perform electrical and functional tests to verify system operability.

3. Maintenance and Repair

Inspect and maintain deicer kits throughout their service life.

- Identify and repair any issues, such as leaks, corrosion, or faulty sensors.

- Conduct periodic maintenance to ensure optimal performance.

4. Compliance and Safety

Adhere to all safety protocols and regulatory requirements.

- Follow established procedures to minimize risks and ensure the safety of both the aircraft and personnel.

- Maintain a clean and organized work area to prevent accidents or contamination.

Interview Tips

Preparing thoroughly for your interview as a Deicer Kit Assembler is crucial to showcase your skills and make a strong impression. Follow these tips to increase your chances of success.

1. Research the Company and Position

Familiarize yourself with the company’s industry, mission, and values. Learn about the specific deicer kit assembler position and its responsibilities.

- Visit the company’s website and LinkedIn page for information.

- Read industry publications and news articles to gain insights into the company and the role.

2. Highlight Relevant Experience and Skills

Emphasize your experience in assembling, inspecting, and testing deicer kits.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Highlight your attention to detail, problem-solving abilities, and commitment to safety.

3. Prepare for Technical Questions

Expect questions that assess your technical knowledge and abilities. Practice answering questions about:

- Deicer kit components and their functions.

- Assembly and installation procedures.

- Inspection and testing methods.

- Troubleshooting and repair techniques.

4. Demonstrate Safety Awareness

Safety is paramount in this role. Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Discuss your experience in adhering to safety regulations and industry best practices.

- Provide examples of your risk assessment and mitigation strategies.

5. Practice the STAR Method

Use the STAR method (Situation, Task, Action, Result) to structure your answers to behavioral interview questions.

- Describe a specific situation or task that highlights your skills.

- Explain the actions you took to address the challenge.

- Quantify the results of your efforts, demonstrating the impact of your actions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Deicer Kit Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!