Are you gearing up for an interview for a Delimber Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Delimber Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

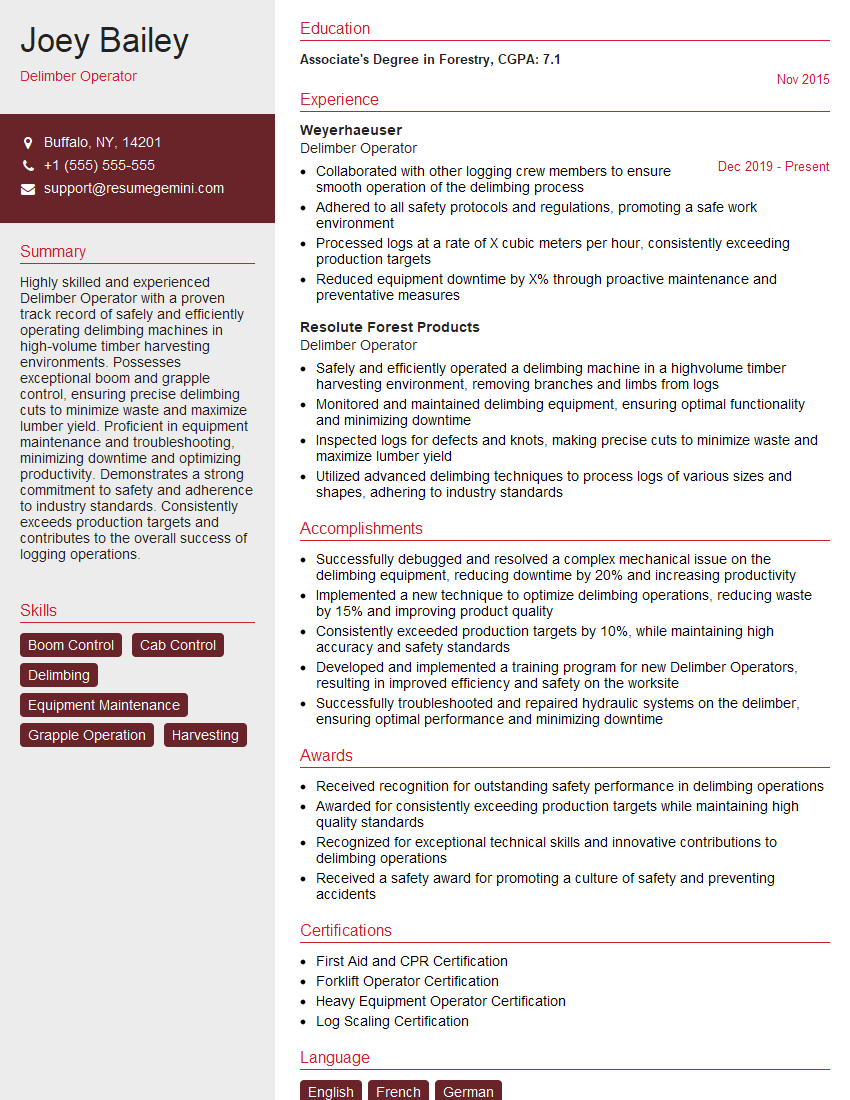

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Delimber Operator

1. What are the primary responsibilities of a Delimber Operator?

- Operate and maintain delimbing equipment to remove branches and limbs from logs.

- Ensure logs are properly aligned and fed into the delimber for efficient delimbing.

- Monitor delimbing process and make adjustments as needed to optimize performance.

- Inspect logs for knots, defects, and other irregularities that may affect delimbing.

- Maintain a clean and organized work area to ensure safety and efficiency.

2. Describe the different types of delimbing equipment you have experience with?

- Hydraulic Fixed Blade Delimber: Uses hydraulic pressure to power a fixed blade that delimbs logs as they pass through.

- Hydraulic Flail Delimber: Utilizes flail chains or discs rotating at high speeds to remove branches.

- Saw Head Delimber: Employs a circular saw blade to cut limbs from logs.

- Knives Delimber: Combines a fixed blade and a moving knife to delimb logs efficiently.

3. What are the key safety considerations when operating a delimber?

- Wear appropriate personal protective equipment (PPE) such as hard hat, safety glasses, gloves, and hearing protection.

- Maintain a safe distance from moving parts and machinery.

- Securely tie down logs before delimbing to prevent them from rolling or moving.

- Inspect equipment regularly for potential hazards and report any issues promptly.

- Never attempt to clear jams or blockages while the equipment is running.

4. How do you troubleshoot common delimbing equipment issues?

- Clogged hydraulic lines: Check for leaks, debris, or kinks in the lines, and clean or replace as necessary.

- Blade or chain damage: Inspect the blade or chain for wear, damage, or dullness, and sharpen or replace it if needed.

- Electrical faults: Verify power supply, check wiring for damage, and ensure sensors and switches are functioning correctly.

- Log alignment problems: Adjust the feed system or log deck to ensure proper alignment for optimal delimbing.

5. How do you work effectively as part of a logging crew?

- Communicate clearly with crew members to coordinate tasks and ensure safety.

- Follow established procedures and protocols for delimbing and log handling.

- Assist other crew members with tasks as needed to maintain efficiency and productivity.

- Maintain a positive and cooperative work environment.

6. How do you stay updated on the latest industry practices and equipment advancements in delimbing operations?

- Attend industry conferences and workshops.

- Read trade publications and journals.

- Network with other Delimber Operators.

- Seek training and certification from equipment manufacturers.

7. Describe a time when you successfully resolved a complex issue with a delimbing machine?

- Detected abnormal vibrations and noises in the delimbing machine.

- Inspected and identified worn bearings as the cause of the issue.

- Safely dismantled the delimbing head and replaced the bearings with new ones.

- Reassembled the machine and ensured proper alignment and calibration.

- Resumed delimbing operations with improved efficiency and reduced downtime.

8. What are your preferred methods for optimizing delimbing productivity?

- Proper log alignment and feeding to minimize time spent adjusting logs.

- Regular maintenance and calibration of equipment to ensure peak performance.

- Training and development for crew members to enhance their skills and efficiency.

- Streamlining communication and coordination within the logging crew.

9. How do you prioritize tasks and manage your time effectively when operating a delimber?

- Establish a clear plan of action for the day based on production targets.

- Prioritize tasks based on urgency and impact on production.

- Delegate tasks to crew members as appropriate to optimize efficiency.

- Monitor progress regularly and adjust priorities as needed.

- Communicate any delays or challenges to supervisors promptly.

10. What is your understanding of sustainable logging practices, and how do you incorporate them into your work as a Delimber Operator?

- Adhere to regulations and guidelines for responsible logging practices.

- Minimize environmental impact by avoiding damage to vegetation and soil.

- Promote reforestation efforts by planting trees and protecting saplings.

- Contribute to forest health by removing diseased or damaged trees.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Delimber Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Delimber Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Delimber Operator is responsible for operating delimbing equipment to remove branches and limbs from felled trees, ensuring efficient and safe production of logs for further processing.

1. Delimbing Operations

Operate delimbing equipment, such as hydraulic or mechanical delimbers, to remove branches and limbs from harvested trees.

- Position and secure tree trunks in the delimber for efficient processing.

- Control delimbing blades or saws to remove limbs and branches cleanly, minimizing waste.

2. Log Handling

Handle and sort delimbed logs, preparing them for further processing or storage.

- Separate logs by species, grade, or size according to established standards.

- Operate conveyors or other equipment to transport logs to designated areas.

3. Equipment Maintenance

Perform routine maintenance and inspections on delimbing equipment to ensure optimal performance.

- Check and lubricate moving parts, inspect blades and saws for wear, and clean equipment regularly.

- Report any equipment malfunctions or maintenance needs to supervisors or mechanics.

4. Safety and Compliance

Adhere to all safety protocols and regulations related to delimbing operations.

- Wear appropriate safety gear, including hard hats, earplugs, and safety glasses.

- Follow safe operating procedures and avoid hazardous situations, such as operating equipment near power lines or unstable loads.

Interview Tips

To ace an interview for a Delimber Operator position, candidates should consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Research the specific Delimber Operator role, its responsibilities, and the required qualifications.

2. Highlight Relevant Skills and Experience

In your resume and cover letter, emphasize your experience in operating delimbing equipment and handling logs. Highlight your knowledge of different types of delimbers, your ability to handle various log sizes and species, and your understanding of safety protocols.

3. Demonstrate Teamwork and Safety Consciousness

Delimbing operations often involve working in a team environment. In your interview, demonstrate your teamwork and communication skills. Emphasize your commitment to safety by highlighting your knowledge of industry regulations and your adherence to safe working practices.

4. Be Prepared for Technical Questions

Interviewers may ask technical questions about delimbing equipment, log handling, and safety procedures. Be prepared to answer questions about the types of delimbers you have operated, the maintenance you have performed, and your understanding of safety protocols.

5. Practice Answering Common Interview Questions

Prepare answers to common interview questions such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses?” Tailor your answers to the specific role and company you are interviewing with.

6. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions about the company’s operations, the specific role, or the advancement opportunities within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Delimber Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.