Are you gearing up for an interview for a Demolition Hammer Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Demolition Hammer Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Demolition Hammer Operator

1. What are the different types of demolition hammers and their uses?

There are several types of demolition hammers, each designed for specific applications. These include:

- Electric demolition hammers: These are powered by electricity and are typically used for lighter demolition work, such as breaking up concrete or brick.

- Pneumatic demolition hammers: These are powered by compressed air and are more powerful than electric models. They are often used for heavy-duty demolition work, such as breaking up concrete or rock.

- Hydraulic demolition hammers: These are powered by hydraulic fluid and are the most powerful type of demolition hammer. They are used for the most demanding demolition tasks, such as breaking up large concrete structures or rock formations.

2. What are the safety precautions that must be taken when operating a demolition hammer?

Proper training

- Only trained and experienced individuals should operate demolition hammers.

Personal protective equipment

- Operators should wear appropriate personal protective equipment (PPE), such as safety glasses, earplugs, gloves, and a hard hat.

Site inspection

- The work area should be inspected for potential hazards, such as overhead wires or gas lines.

Safe operation

- Demolition hammers should be operated in a safe manner, avoiding sudden movements or excessive force.

- Operators should ensure that the hammer is properly secured before use.

- Hammer should not be used if there is any damage or broken parts.

3. What are the common maintenance tasks that need to be performed on a demolition hammer?

Regular maintenance is essential to ensure the safe and efficient operation of a demolition hammer. Common maintenance tasks include:

- Cleaning: The hammer should be cleaned regularly to remove dust and debris. This will help to prevent overheating and extend the life of the hammer.

- Lubrication: The hammer should be lubricated according to the manufacturer’s instructions. This will help to reduce friction and wear on the moving parts.

- Inspection: The hammer should be inspected regularly for any signs of damage or wear. Any damaged or worn parts should be replaced immediately.

4. What are the different factors that can affect the performance of a demolition hammer?

The performance of a demolition hammer can be affected by a number of factors, including:

- Type of hammer: The type of hammer (electric, pneumatic, or hydraulic) can affect its power, weight, and handling characteristics.

- Hammer weight: The weight of the hammer can affect its impact force and vibration levels.

- Bit size: The size of the bit can affect the hammer’s penetration rate and efficiency.

- Material being demolished: The type of material being demolished can affect the hammer’s performance. Harder materials, such as concrete, require more force to break up than softer materials, such as drywall.

5. What are the signs that a demolition hammer is in need of repair?

There are several signs that may indicate that a demolition hammer is in need of repair, including:

- Reduced power: The hammer may not be able to break up material as effectively as it used to.

- Excessive vibration: The hammer may vibrate more than normal, which can be a sign of worn or damaged bearings.

- Unusual noises: The hammer may make unusual noises, such as squealing or grinding, which can be a sign of internal damage.

- Leaking oil or hydraulic fluid: A leak may indicate a damaged seal or hose.

6. What are the different techniques that can be used to improve the efficiency of a demolition hammer?

There are several techniques that can be used to improve the efficiency of a demolition hammer, including:

- Using the correct bit: The size and type of bit can affect the hammer’s performance. Using the correct bit for the job will help to improve efficiency.

- Properly positioning the hammer: The hammer should be positioned properly against the material being demolished. This will help to ensure that the force of the hammer is applied in the most effective way.

- Using the correct grip: The operator should use a firm grip on the hammer to help control the tool and prevent it from moving around.

7. What are the different types of bits that can be used with a demolition hammer?

There are a variety of bits that can be used with a demolition hammer, each designed for a specific purpose. These include:

- Pointed bits: These bits are used for breaking up concrete, brick, and other hard materials.

- Chisel bits: These bits are used for chipping away at concrete, brick, and other hard materials.

- Spade bits: These bits are used for digging trenches and holes in concrete, brick, and other hard materials.

- Tamping bits: These bits are used for compacting soil and gravel.

8. What are the different factors that can affect the lifespan of a demolition hammer?

The lifespan of a demolition hammer can be affected by a number of factors, including:

- Usage: The frequency and intensity of use can affect the lifespan of the hammer.

- Maintenance: Regular maintenance, such as cleaning, lubrication, and inspection, can help to extend the lifespan of the hammer.

- Environment: The environment in which the hammer is used can affect its lifespan. Hammers used in dusty or wet conditions may have a shorter lifespan than hammers used in clean, dry conditions.

9. What are the different safety features that are available on demolition hammers?

Demolition hammers are equipped with a variety of safety features to help protect the operator, including:

- Anti-vibration systems: These systems help to reduce the vibration levels transmitted to the operator.

- Dust collection systems: These systems help to collect dust and debris generated by the hammer.

- Safety handles: These handles help to protect the operator’s hands from injury.

- Trigger locks: These locks prevent the hammer from being accidentally activated.

10. What are the different applications for demolition hammers?

Demolition hammers are used in a variety of applications, including:

- Demolition: Demolition hammers are used to break up concrete, brick, and other hard materials.

- Construction: Demolition hammers are used to remove old concrete and other materials during construction projects.

- Renovation: Demolition hammers are used to remove old tiles, fixtures, and other materials during renovation projects.

- Mining: Demolition hammers are used to break up rock and other materials in mining operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Demolition Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Demolition Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Demolition Hammer Operator is a skilled professional responsible for operating and maintaining a variety of demolition tools and equipment. They work in hazardous environments to demolish structures, remove debris, and perform other tasks associated with the construction industry. Their primary duties include:

1. Operate Demolition Equipment

Demolition Hammer Operators use various equipment and tools for demolition tasks, such as:

- Hydraulic breakers

- Pneumatic hammers

- Sledgehammers

- Chisels

- Picks

2. Follow Safety Regulations

Working with heavy machinery and explosives poses significant risks, so a Demolition Hammer Operator must strictly follow safety guidelines and regulations to ensure their safety and the safety of those around them.

3. Clear Debris

After demolishing a structure, the operator is responsible for clearing the debris and ensuring the site is safe for further work or cleanup.

4. Maintain Equipment

To ensure the efficient and safe operation of equipment, Demolition Hammer Operators must perform regular maintenance, which includes:

- Inspecting equipment for damage

- Lubricating moving parts

- Replacing worn or damaged parts

Interview Tips

To ace your Demolition Hammer Operator interview, you should:

1. Highlight Safety Experience

Since safety is paramount in this role, emphasize your strict adherence to safety regulations and your experience in working in hazardous environments.

2. Demonstrate Physical Fitness

This job requires physical strength, so be prepared to demonstrate your fitness level and ability to perform strenuous tasks.

3. Research Common Interview Questions

Prepare for common interview questions, such as:

- “What is your experience operating demolition equipment?”

- “How do you stay safe while working with heavy machinery?”

- “What are the challenges you have faced as a Demolition Hammer Operator?”

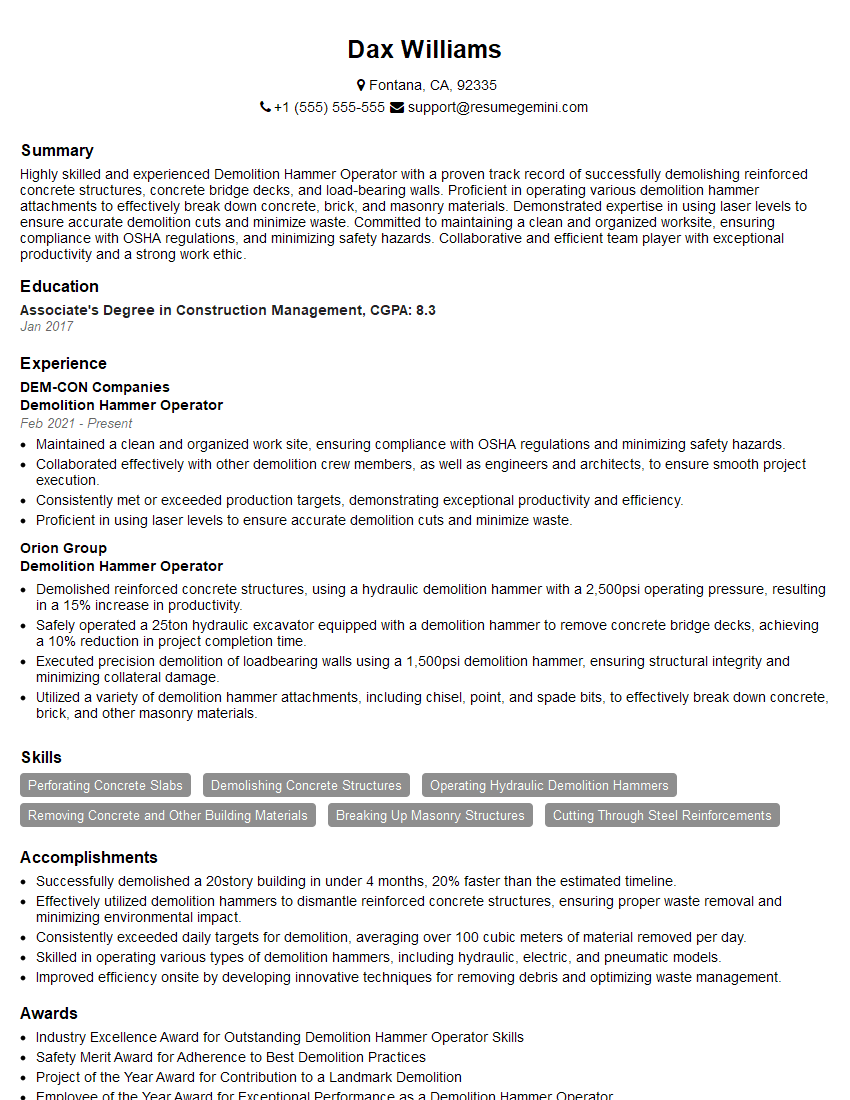

4. Bring a Resume with Relevant Experience

Your resume should clearly highlight your experience and skills related to demolition work, including any certifications or training.

5. Dress Professionally

First impressions matter, so dress professionally and appropriately for the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Demolition Hammer Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.