Feeling lost in a sea of interview questions? Landed that dream interview for Dental Mold Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dental Mold Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

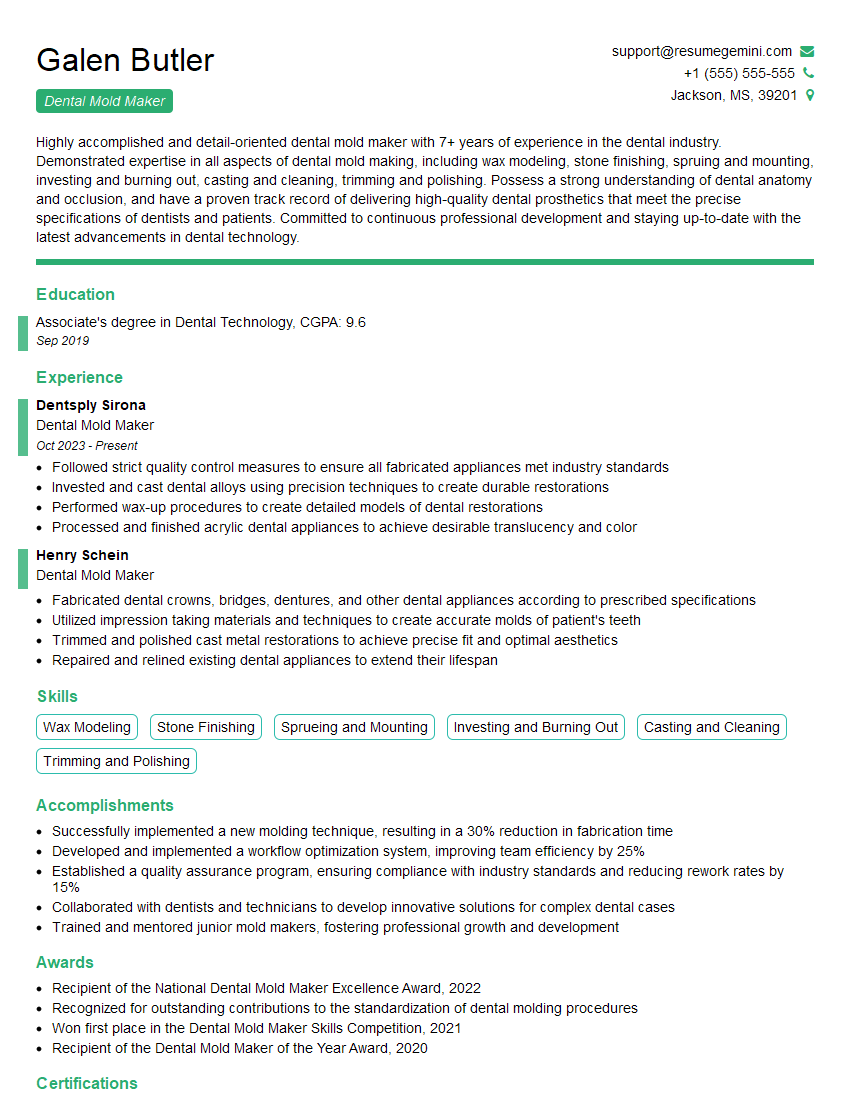

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dental Mold Maker

1. Describe the steps involved in the dental mold making process?

- Taking an impression of the patient’s mouth

- Creating a wax pattern of the teeth

- Investing the wax pattern in a mold

- Casting the mold in metal

- Finishing and polishing the casting

2. What are the different types of dental mold materials?

- Alginate

- Silicone

- PVS (polyether vinyl siloxane)

- Hydrocolloid

- Zeolite

3. What are the advantages and disadvantages of each type of material?

Alginate

- Advantages: Inexpensive, easy to use, good detail reproduction

- Disadvantages: Short working time, low tear strength, can be distorted easily

Silicone

- Advantages: High tear strength, good detail reproduction, long working time

- Disadvantages: Expensive, can be difficult to use, can inhibit the polymerization of acrylic resins

PVS

- Advantages: High tear strength, good detail reproduction, long working time, can be used with acrylic resins

- Disadvantages: Expensive, can be difficult to use

Hydrocolloid

- Advantages: Inexpensive, easy to use, good detail reproduction

- Disadvantages: Short working time, low tear strength, can be distorted easily

Zeolite

- Advantages: High tear strength, good detail reproduction, accurate bite registration

- Disadvantages: Expensive, can be difficult to use, can irritate the skin

4. What are the common problems that can occur during the dental mold making process?

- Air bubbles

- Voids

- Undercuts

- Distortion

- Fracture

5. How can these problems be prevented or corrected?

Air bubbles

- Use a vacuum mixer to remove air bubbles from the impression material

- Tap the impression tray gently to release any trapped air

Voids

- Make sure the impression tray is fully seated in the patient’s mouth

- Use a heavy body impression material to fill any undercuts

Undercuts

- Block out any undercuts with wax or a similar material

- Use a high viscosity impression material that will not flow into the undercuts

Distortion

- Use a rigid impression tray

- Support the impression with a bite registration

Fracture

- Handle the mold carefully

- Use a sharp instrument to trim the mold

6. What are the different types of dental mold trimmers?

- Hand trimmers

- Rotary trimmers

- Laser trimmers

7. What are the advantages and disadvantages of each type of trimmer?

Hand trimmers

- Advantages: Inexpensive, easy to use, portable

- Disadvantages: Slow, can be difficult to get a smooth finish

Rotary trimmers

- Advantages: Fast, can get a smooth finish

- Disadvantages: Expensive, can be dangerous if not used properly

Laser trimmers

- Advantages: Fast, can get a very smooth finish

- Disadvantages: Expensive, can be dangerous if not used properly

8. What are the safety precautions that must be taken when using a dental mold trimmer?

- Wear eye protection

- Wear a dust mask

- Use the trimmer in a well-ventilated area

- Do not use the trimmer on wet molds

- Keep the trimmer clean and free of debris

9. What are the different types of dental mold finishing and polishing materials?

- Abrasive stones

- Abrasive paper

- Abrasive powders

- Buffing wheels

- Polishing compounds

10. What are the advantages and disadvantages of each type of material?

Abrasive stones

- Advantages: Fast, can remove large amounts of material

- Disadvantages: Can be difficult to control, can leave a rough finish

Abrasive paper

- Advantages: Inexpensive, easy to use, can get a smooth finish

- Disadvantages: Slow, can clog easily

Abrasive powders

- Advantages: Can be used to get a very fine finish

- Disadvantages: Can be messy, can be difficult to control

Buffing wheels

- Advantages: Can get a high shine

- Disadvantages: Can be expensive, can be difficult to use

Polishing compounds

- Advantages: Can get a very high shine

- Disadvantages: Can be messy, can be difficult to apply

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dental Mold Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dental Mold Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary responsibility of a Dental Mold Maker is to create and maintain dental molds used in the production of crowns, bridges, dentures, and other dental prosthetics.

1. Mold Fabrication

Using impressions taken from patients’ teeth, dental mold makers create accurate and detailed molds using various materials, such as wax, plaster, or silicone.

- Interpret dental impressions and create molds that accurately reflect the patient’s oral anatomy.

- Select and use appropriate materials for mold fabrication, ensuring precision and durability.

2. Mold Maintenance

Dental mold makers are responsible for maintaining and repairing molds to ensure their continued accuracy and functionality.

- Inspect molds regularly for wear and tear, and make necessary repairs or modifications.

- Clean and sterilize molds according to established protocols to prevent contamination.

3. Quality Assurance

Ensuring the accuracy and quality of dental molds is crucial for the success of dental prosthetics. Dental mold makers play a vital role in this process.

- Conduct thorough inspections of molds to identify any defects or imperfections that could affect the final product.

- Collaborate with dentists and dental technicians to address any issues or concerns related to mold accuracy.

4. Equipment Operation

Dental mold makers utilize specialized equipment and machinery in their work.

- Operate dental laboratory equipment, such as wax injectors, mold presses, and casting machines.

- Maintain and calibrate equipment to ensure optimal performance and accuracy.

Interview Tips

Preparing for a dental mold maker interview requires a thorough understanding of the role and its responsibilities, as well as effective communication and presentation skills.

1. Research the Company and Position

Before the interview, take the time to research the dental laboratory or clinic and the specific position you’re applying for. This will help you tailor your answers and demonstrate your knowledge of the industry and the company’s values.

- Visit the company’s website and social media pages to gather information about their services, team, and culture.

- Read industry publications and articles to stay up-to-date on the latest techniques and advancements in dental mold making.

2. Highlight Your Skills and Experience

In your resume and during the interview, emphasize your technical skills and experience in dental mold making. Use specific examples to demonstrate your proficiency in creating accurate and high-quality molds.

- Quantify your accomplishments whenever possible, using numbers and data to showcase the impact of your work.

- Be prepared to discuss your experience with different materials and techniques used in mold making.

3. Show Your Passion for the Field

Dental mold making requires precision, attention to detail, and a genuine interest in the field. Express your passion for creating and maintaining high-quality dental molds that contribute to the success of dental prosthetics.

- Share examples of how you’ve gone above and beyond in your previous roles to ensure the accuracy and quality of molds.

- Explain why you’re excited about the opportunity to work in this field and contribute your skills to the team.

4. Prepare for Common Interview Questions

Research common interview questions for dental mold makers and prepare thoughtful answers that highlight your qualifications and enthusiasm for the position.

- Practice answering questions about your experience with different mold materials and techniques.

- Prepare examples of how you’ve handled challenges or solved problems in your previous roles.

Next Step:

Now that you’re armed with the knowledge of Dental Mold Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dental Mold Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini