Are you gearing up for an interview for a Derrick Builder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Derrick Builder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

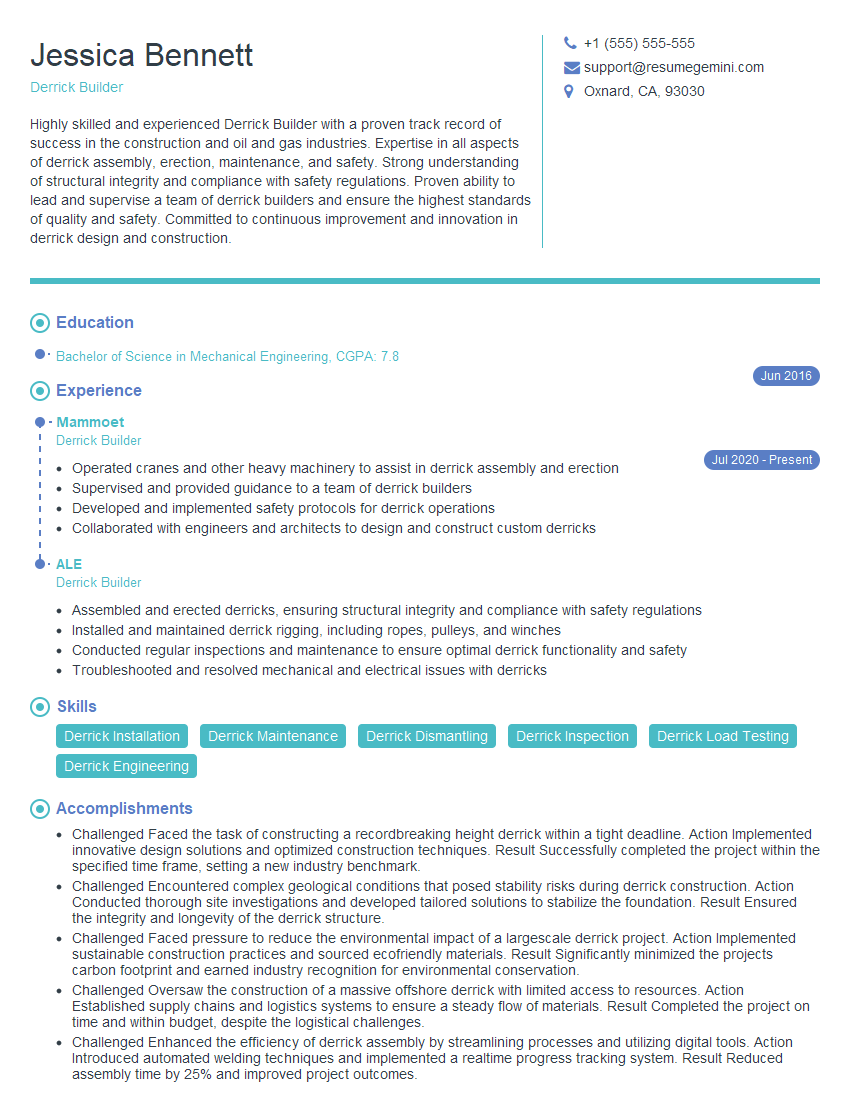

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Derrick Builder

1. What is the difference between a single and double girder crane?

A single girder crane is a crane that has a single main beam, while a double girder crane has two main beams. The main beams are the horizontal beams that support the hoist and trolley. Single girder cranes are typically used for lighter loads, while double girder cranes are used for heavier loads.

2. What are the different types of hoists that can be used on a crane?

Wire rope hoists

- Wire rope hoists are the most common type of hoist used on cranes. They are durable and reliable, and can lift heavy loads.

Chain hoists

- Chain hoists are less common than wire rope hoists, but they are still used in some applications. They are lightweight and portable, and can be used to lift lighter loads.

3. What are the different types of trolleys that can be used on a crane?

There are two main types of trolleys that can be used on a crane: end trucks and bridge trolleys. End trucks are mounted on the ends of the main beams, while bridge trolleys are mounted on the bridge of the crane. End trucks are typically used for lighter loads, while bridge trolleys are used for heavier loads.

4. What are the different types of crane controls?

There are three main types of crane controls: pendant controls, radio controls, and cabin controls. Pendant controls are the most common type of control, and they are typically used for smaller cranes. Radio controls are used for larger cranes, and they allow the operator to control the crane from a distance. Cabin controls are used for the largest cranes, and they allow the operator to control the crane from a cabin that is mounted on the crane.

5. What are the different types of crane safety features?

There are many different types of crane safety features, including: overload protection, overspeed protection, and anti-collision systems. Overload protection prevents the crane from lifting loads that are too heavy for it. Overspeed protection prevents the crane from moving too fast. Anti-collision systems prevent the crane from colliding with other objects.

6. What are the different types of crane inspections?

There are two main types of crane inspections: daily inspections and annual inspections. Daily inspections are performed by the crane operator before each use of the crane. Annual inspections are performed by a qualified inspector once a year.

7. What are the different types of crane maintenance?

There are many different types of crane maintenance, including: preventive maintenance, corrective maintenance, and emergency maintenance. Preventive maintenance is performed on a regular basis to prevent problems from occurring. Corrective maintenance is performed to fix problems that have already occurred. Emergency maintenance is performed to fix problems that are critical and require immediate attention.

8. What are the different types of crane training?

There are many different types of crane training, including: operator training, inspector training, and maintenance training. Operator training is required for anyone who operates a crane. Inspector training is required for anyone who inspects cranes. Maintenance training is required for anyone who maintains cranes.

9. What are the different types of crane regulations?

There are many different types of crane regulations, including: OSHA regulations, ANSI regulations, and ASME regulations. OSHA regulations are enforced by the Occupational Safety and Health Administration. ANSI regulations are developed by the American National Standards Institute. ASME regulations are developed by the American Society of Mechanical Engineers.

10. What are the different types of crane certification?

There are many different types of crane certification, including: operator certification, inspector certification, and maintenance certification. Operator certification is required for anyone who operates a crane. Inspector certification is required for anyone who inspects cranes. Maintenance certification is required for anyone who maintains cranes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Derrick Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Derrick Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Derrick Builder, your primary responsibility is to design, construct, and maintain derricks used in various industries, including oil and gas drilling, construction, and shipbuilding.

1. Design and Engineering

Analyze project specifications and determine the appropriate design for the derrick.

- Calculate and specify material requirements, including steel, cables, and other components.

- Create detailed blueprints and drawings.

2. Construction and Fabrication

Supervise the fabrication and assembly of derrick components.

- Coordinate with welders, machinists, and other trades.

- Ensure compliance with safety regulations and quality standards.

3. Installation and Commissioning

Direct the installation of the derrick on-site.

- Inspect and test the derrick to ensure proper functionality.

- Train operators on safe and efficient use.

4. Maintenance and Repair

Perform regular inspections and preventive maintenance on derricks.

- Diagnose and repair any malfunctions or defects.

- Maintain records and document maintenance activities.

Interview Tips

Preparing for a Derrick Builder interview requires thorough research and practice. Follow these tips to increase your chances of success:

1. Research the Company and Position

Before the interview, take the time to learn about the company, its history, and its products/services. Also, carefully review the job description to understand the specific requirements and responsibilities.

- Visit the company website and LinkedIn profile.

- Read industry news and articles related to derrick building.

2. Highlight Your Technical Skills

Emphasize your proficiency in structural design, engineering principles, and construction methods. Provide specific examples of projects you have worked on and the results you achieved.

- Quantify your accomplishments with metrics, such as the number of derricks built or the cost savings achieved.

- Describe your experience using CAD software and other industry-specific tools.

3. Showcase Your Safety Mindset

Safety is paramount in derrick building. Demonstrate your understanding of industry standards and regulations, as well as your commitment to creating and maintaining a safe work environment.

- Share examples of how you have implemented safety measures on previous projects.

- Explain how you stay up-to-date on safety best practices.

4. Prepare for Behavioral Questions

In addition to technical skills, interviewers will also assess your teamwork, problem-solving, and communication abilities. Be prepared to answer behavioral questions using the STAR method:

- Situation: Describe the situation you were in.

- Task: Explain your role and responsibilities.

- Action: Describe the specific actions you took.

- Result: Quantify the results of your actions.

5. Practice Your Answers

Practice answering the most common interview questions out loud to improve your delivery and confidence. Seek feedback from friends, family, or a career counselor.

- Record yourself answering questions and watch the playback.

- Time yourself to ensure you can answer within the allotted time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Derrick Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!