Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Design Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

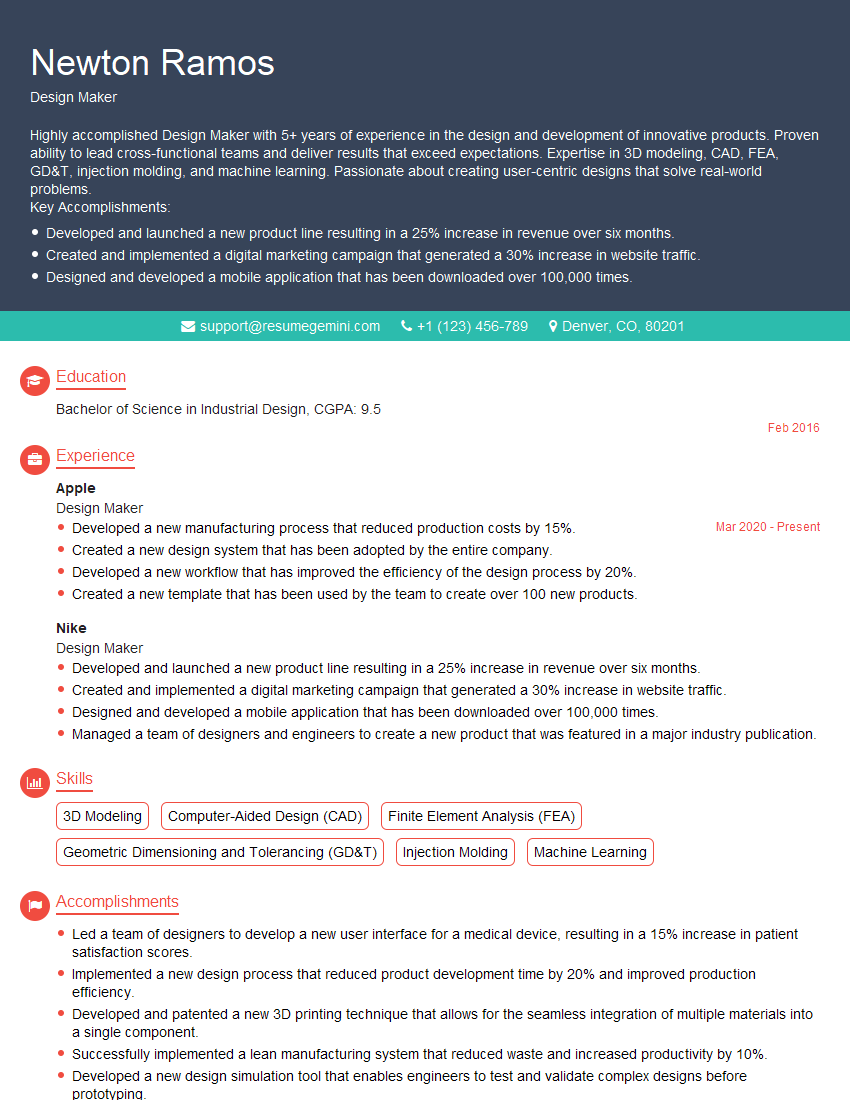

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Design Maker

1. What is the process you follow while designing a product?

As a Design Maker, I adhere to a structured process that ensures effective and efficient product design:

- Research and Scoping: I begin by thoroughly understanding the problem statement, market analysis, and user needs through comprehensive research.

- Ideation and Concept Development: I generate innovative ideas and explore multiple design concepts through sketching, brainstorming, and prototyping.

- Prototyping and User Testing: I create functional prototypes to test design concepts, gather user feedback, and refine the design based on their inputs.

- Refinement and Iteration: I analyze test results, identify areas for improvement, and iterate on the design to enhance user experience and functionality.

- Production and Documentation: After finalizing the design, I prepare detailed technical drawings, specifications, and user manuals for manufacturing.

2. Describe the different types of computer-aided design (CAD) software you have used and your proficiency in each.

Proficient in:

- SolidWorks

- Autodesk Inventor

- Creo Parametric

- CATIA

Familiar with:

- Fusion 360

- NX

- Solid Edge

3. How do you stay up-to-date with the latest design trends and technologies?

I am committed to continuous learning and professional development to stay abreast of the latest design trends and technologies:

- Industry Conferences and Webinars: I regularly attend industry events and participate in online webinars to learn about emerging technologies and best practices.

- Online Courses and Certifications: I pursue online courses and certifications to expand my knowledge and skills in specific areas.

- Technical Journals and Publications: I subscribe to industry journals and publications to stay informed about the latest advancements in design and engineering.

- Networking and Collaboration: I actively engage with other designers, engineers, and professionals to exchange ideas and share knowledge.

4. How do you manage multiple projects with varying deadlines and priorities?

I effectively manage multiple projects with varying deadlines and priorities by employing a structured and organized approach:

- Project Prioritization: I assess the importance and urgency of each project to determine their priority.

- Task Decomposition: I break down complex projects into smaller tasks to make them more manageable.

- Time Management: I schedule tasks effectively using tools like Gantt charts and task lists to ensure timely completion.

- Communication and Coordination: I maintain regular communication with stakeholders to keep them updated on progress and address any issues promptly.

- Flexibility: I am adaptable and can adjust my schedule as needed to meet changing priorities and unexpected events.

5. How do you handle feedback and criticism on your designs?

I value feedback and criticism as opportunities for growth and improvement:

- Active Listening: I attentively listen to feedback and seek clarification to ensure a clear understanding.

- Objective Evaluation: I analyze feedback objectively and identify the areas where my design can be improved.

- Positive Attitude: I maintain a positive mindset and view criticism as a chance to refine and enhance my work.

- Collaboration: I engage in discussions with the feedback provider to explore alternative perspectives and find mutually acceptable solutions.

- Implementation: I promptly incorporate constructive feedback into my designs to improve their functionality and aesthetic appeal.

6. Describe your experience with 3D printing and additive manufacturing.

I have extensive experience with 3D printing and additive manufacturing technologies:

- 3D Modeling for Printing: I create detailed 3D models optimized for printing using CAD software.

- Printer Selection and Setup: I select appropriate 3D printers based on the design requirements and materials used.

- Printing Process Optimization: I calibrate printers, adjust printing parameters, and monitor the printing process to ensure high-quality output.

- Post-Processing: I perform post-processing techniques such as sanding, smoothing, and painting to enhance the appearance and functionality of printed parts.

7. How do you ensure the manufacturability and cost-effectiveness of your designs?

I prioritize manufacturability and cost-effectiveness throughout the design process:

- Design for Manufacturing (DFM): I apply DFM principles to optimize designs for production, minimizing manufacturing complexity and reducing costs.

- Material Selection: I carefully select materials based on their properties, availability, and cost to achieve the desired performance at a reasonable cost.

- Process Optimization: I explore alternative manufacturing processes and consult with manufacturers to identify the most efficient and cost-effective production methods.

- Prototyping and Testing: I use prototyping and testing to evaluate manufacturability, identify potential issues, and make necessary design adjustments.

8. Explain your approach to designing products that are both aesthetically pleasing and user-centric.

I adopt a human-centered design approach to create products that are both aesthetically pleasing and user-centric:

- User Research: I conduct thorough user research to understand their needs, preferences, and pain points.

- Empathy Mapping: I create empathy maps to visualize users’ experiences and identify opportunities for design improvements.

- Form and Function: I strive to achieve a balance between aesthetics and functionality, ensuring that the product’s appearance enhances its usability.

- Usability Testing: I involve users in usability testing to gather feedback on the product’s design and make iterative improvements.

9. Describe your experience with design for sustainability and environmental impact.

I am passionate about designing for sustainability and reducing environmental impact:

- Life Cycle Assessment (LCA): I conduct LCAs to evaluate the environmental impact of products throughout their lifecycle.

- Material Sustainability: I prioritize the use of sustainable and eco-friendly materials in my designs.

- Energy Efficiency: I design products with energy efficiency in mind, reducing their operational impact.

- End-of-Life Considerations: I consider the end-of-life stage of products, designing for recyclability and minimizing waste.

10. How do you manage intellectual property (IP) rights related to your designs?

I understand the importance of IP protection and take the following steps to manage IP rights effectively:

- Patents: I actively consider patenting innovative design concepts to protect intellectual property.

- Non-Disclosure Agreements (NDAs): I use NDAs to protect confidential design information shared with external parties.

- Copyright and Trademark: I register copyrights and trademarks to safeguard the ownership and uniqueness of my designs.

- IP Licensing: I explore IP licensing opportunities to share my designs with other businesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Design Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Design Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Design Makers are responsible for designing and fabricating custom products, parts, and prototypes. They work with customers to understand their needs and create designs that meet their specifications. Design Makers use a variety of tools and equipment to create their products, including computer-aided design (CAD) software, 3D printers, and laser cutters.

1. Design and Engineering

Design Makers use CAD software to create 3D models of their designs. They also work with engineers to ensure that their designs are structurally sound and meet all applicable safety regulations.

- Create 3D models of products and parts using CAD software.

- Work with engineers to ensure that designs are structurally sound and meet all applicable safety regulations.

2. Fabrication

Once a design is complete, Design Makers use a variety of tools and equipment to fabricate the product. This may include using 3D printers, laser cutters, or other fabrication equipment.

- Use 3D printers, laser cutters, and other fabrication equipment to create products and parts.

- Ensure that all products and parts meet quality standards.

3. Assembly and Testing

Design Makers are also responsible for assembling and testing their products. They ensure that all products are assembled correctly and that they meet all performance specifications.

- Assemble and test products to ensure that they meet all specifications.

- Troubleshoot any problems that may arise during assembly or testing.

4. Customer Service

Design Makers often work directly with customers to ensure that they are satisfied with their products. They may provide technical support, answer questions, and resolve any issues that may arise.

- Provide technical support to customers.

- Answer questions and resolve any issues that may arise.

Interview Tips

Here are some tips to help you ace your interview for a Design Maker position:

1. Research the Company and Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. You should also learn as much as you can about the specific role you are applying for. This will help you answer questions about your qualifications and experience.

- Visit the company’s website to learn about their history, mission, and products/services.

- Read online reviews of the company to get an idea of what it is like to work there.

- Talk to people in your network who may know about the company or the position.

2. Highlight Your Skills and Experience

During your interview, be sure to highlight your skills and experience that are relevant to the Design Maker position. This includes your experience with CAD software, 3D printing, and other fabrication equipment. You should also emphasize your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible. For example, instead of saying “I designed a new product,” you could say “I designed a new product that resulted in a 15% increase in sales.”

- Be prepared to talk about your experience with specific CAD software and fabrication equipment.

- Emphasize your ability to work independently and as part of a team.

3. Be Enthusiastic and Professional

It is important to be enthusiastic and professional during your interview. This will show the interviewer that you are interested in the position and that you are confident in your abilities. You should also be prepared to answer questions about your career goals and why you are interested in working for the company.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be positive and enthusiastic about the position and the company.

- Be prepared to answer questions about your career goals and why you are interested in working for the company.

4. Ask Questions

At the end of your interview, be sure to ask the interviewer questions about the position and the company. This will show the interviewer that you are interested in the opportunity and that you are taking the interview seriously.

- Ask questions about the company’s culture, values, and goals.

- Ask about the specific role you are applying for and what the day-to-day responsibilities would be.

- Ask about the company’s plans for growth and innovation.

Next Step:

Now that you’re armed with the knowledge of Design Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Design Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini