Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Design Printing Machine Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

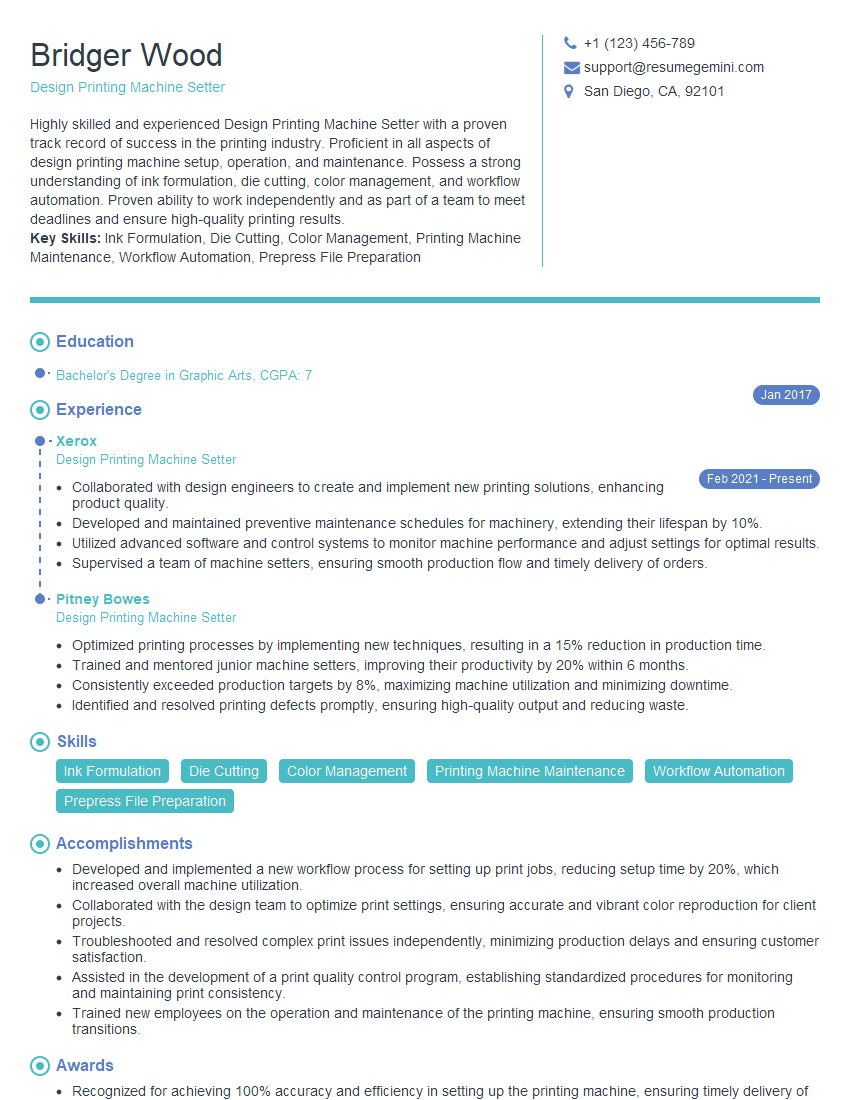

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Design Printing Machine Setter

1. How do you ensure the accuracy of the printing machine’s settings?

To ensure the accuracy of the printing machine’s settings, I follow a systematic approach that involves:

- Carefully reviewing the print job specifications and requirements.

- Performing thorough machine inspections and calibrations before each print run.

- Using precision measuring tools to verify and adjust settings, such as paper registration, ink density, and printhead alignment.

- Conducting test prints to confirm the accuracy of the settings before proceeding with the actual print job.

- Continuously monitoring the printing process and making adjustments as necessary to maintain optimal print quality.

2. Describe the different types of printing presses you have experience with and their key features.

I have experience operating and setting up various types of printing presses, including:

Offset Printing Presses

- Capable of producing high-quality, full-color prints on various paper stocks.

- Use plates to transfer ink to paper, allowing for precise registration and detail.

Digital Printing Presses

- Utilize digital technology to directly print from electronic files, eliminating the need for plates.

- Offer faster turnaround times and variable data printing capabilities.

Flexographic Printing Presses

- Designed for high-volume printing on flexible materials, such as packaging and labels.

- Use flexible printing plates and liquid inks for durable and vibrant prints.

3. How do you handle troubleshooting and maintenance of the printing machine?

In the event of any issues with the printing machine, I follow a structured troubleshooting and maintenance process:

- Identify the problem and its potential causes using technical knowledge and experience.

- Check for error messages or indicators on the machine’s control panel.

- Perform physical inspections of the machine’s components, such as ink levels, paper feed mechanisms, and printheads.

- Refer to technical manuals and consult with colleagues or manufacturers for assistance if necessary.

- Execute repairs or adjustments following safety protocols and using appropriate tools.

- Conduct post-maintenance testing to ensure the machine is operating correctly before resuming print jobs.

4. What techniques do you use to optimize print quality while minimizing waste?

To optimize print quality while minimizing waste, I employ the following techniques:

- Properly calibrating the printing machine to ensure accurate color reproduction and paper registration.

- Using high-quality printing materials, such as paper and ink, that are compatible with the machine and the job requirements.

- Optimizing print settings, such as resolution, ink density, and color profiles, to achieve the desired print quality.

- Performing regular maintenance and cleaning of the printing machine to prevent mechanical issues and ensure optimal performance.

- Monitoring print jobs closely and adjusting settings as needed to minimize errors and waste.

5. How do you stay up-to-date with the latest printing technologies and industry best practices?

To stay current with the latest printing technologies and best practices, I engage in ongoing professional development activities:

- Attending industry conferences, workshops, and trade shows.

- Reading industry publications, technical journals, and online resources.

- Participating in online forums and discussions with other printing professionals.

- Seeking training from manufacturers and suppliers on new equipment and techniques.

- Networking with colleagues and experts in the field to share knowledge and insights.

6. Describe your process for managing multiple print jobs simultaneously.

When managing multiple print jobs simultaneously, I employ a systematic approach:

- Prioritize jobs based on deadlines and customer requirements.

- Plan the job sequence to optimize machine utilization and minimize downtime.

- Set up and configure each machine for the specific job requirements, such as paper size, ink colors, and print settings.

- Monitor the progress of each job closely and make adjustments as needed to maintain quality and efficiency.

- Communicate regularly with customers to provide updates and resolve any issues promptly.

7. How do you ensure that printed materials meet customer specifications and quality standards?

To ensure that printed materials meet customer specifications and quality standards, I follow a rigorous process:

- Reviewing customer specifications thoroughly and clarifying any requirements.

- Inspecting printed materials carefully for accuracy, color fidelity, and overall quality.

- Using quality control tools, such as densitometers and spectrophotometers, to measure and verify print quality.

- Communicating with customers regularly to provide updates and address any concerns.

- Maintaining records of print jobs and quality control measurements for future reference.

8. How do you handle customer complaints and resolve issues related to print quality?

When handling customer complaints and resolving issues related to print quality, I prioritize the following steps:

- Listening attentively to the customer’s complaint and understanding their concerns.

- Inspecting the printed materials and identifying potential causes of the issue.

- Consulting with colleagues or technical experts to gather additional insights and solutions.

- Communicating clearly and promptly with the customer to explain the issue and proposed solutions.

- Implementing corrective actions and reprinting or adjusting the print job as necessary.

9. How do you maintain a clean and organized work area, especially around the printing machine?

To maintain a clean and organized work area, particularly around the printing machine, I adhere to the following practices:

- Regularly cleaning and inspecting the printing machine, including wiping down surfaces, clearing debris, and replacing consumables.

- Organizing printed materials and supplies in designated areas to prevent clutter and ensure easy access.

- Maintaining a schedule for cleaning and maintenance tasks to ensure the work area remains hygienic and efficient.

- Encouraging a culture of cleanliness and organization among colleagues to promote a safe and productive work environment.

10. How do you measure and evaluate your own performance as a Design Printing Machine Setter?

I measure and evaluate my performance as a Design Printing Machine Setter through the following metrics:

- Print quality and accuracy, as determined by customer feedback and quality control inspections.

- Machine uptime and efficiency, including minimizing downtime and maximizing machine utilization.

- Meeting production deadlines and customer expectations consistently.

- Handling troubleshooting and maintenance tasks effectively and promptly.

- Adhering to safety protocols and maintaining a clean and organized work area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Design Printing Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Design Printing Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Design Printing Machine Setters are responsible for setting up, operating, and maintaining design printing machines to print various designs on materials. Their key responsibilities include:

1. Machine Setup and Operation

Setting up, calibrating, and operating design printing machines, ensuring optimal performance and precision.

- Loading and aligning printing materials, such as paper, vinyl, or fabric.

- Adjusting machine settings, including print speed, ink flow, and temperature.

2. Design Preparation and File Management

Preparing and optimizing digital design files for printing, ensuring accurate and high-quality results.

- Converting design files into compatible formats for printing machines.

- Managing and organizing design files, maintaining a digital archive for future reference.

3. Color Matching and Quality Control

Matching colors accurately between digital designs and printed products, ensuring consistency and client satisfaction.

- Using colorimeters or spectrophotometers to measure and adjust colors.

- Inspecting printed products for defects, ensuring they meet quality standards.

4. Machine Maintenance and Troubleshooting

Performing regular maintenance on design printing machines, ensuring optimal performance and preventing downtime.

- Cleaning and lubricating machine components.

- Troubleshooting and resolving machine malfunctions promptly, minimizing production delays.

Interview Tips

Preparing for an interview for a Design Printing Machine Setter position requires careful planning and practice. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company, its products or services, and the specific responsibilities of the Design Printing Machine Setter role. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your understanding of the industry.

- Visit the company’s website and social media pages to gather information.

- Read industry articles and blogs to stay updated on the latest printing technologies and trends.

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience in design printing machine setup, operation, and maintenance. Provide specific examples of your accomplishments in previous roles.

- Quantify your results whenever possible. For example, instead of saying “I set up and operated design printing machines,” you could say, “I set up and operated design printing machines, resulting in a 15% increase in production efficiency.”

- Be prepared to discuss your experience with different types of printing machines and materials.

3. Demonstrate Your Problem-Solving Abilities

Interviewers will be interested in your ability to troubleshoot and resolve printing issues. Share examples of how you have successfully diagnosed and fixed machine malfunctions in the past.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Be specific about the steps you took to identify and resolve the problem.

4. Showcase Your Communication and Teamwork Skills

Design Printing Machine Setters often work in teams and interact with clients. Highlight your ability to communicate effectively and collaborate with others.

- Provide examples of how you have successfully communicated with clients about design specifications and printing requirements.

- Discuss your experience working in a team environment and how you contribute to the group’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Design Printing Machine Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!