Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Desolderer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Desolderer so you can tailor your answers to impress potential employers.

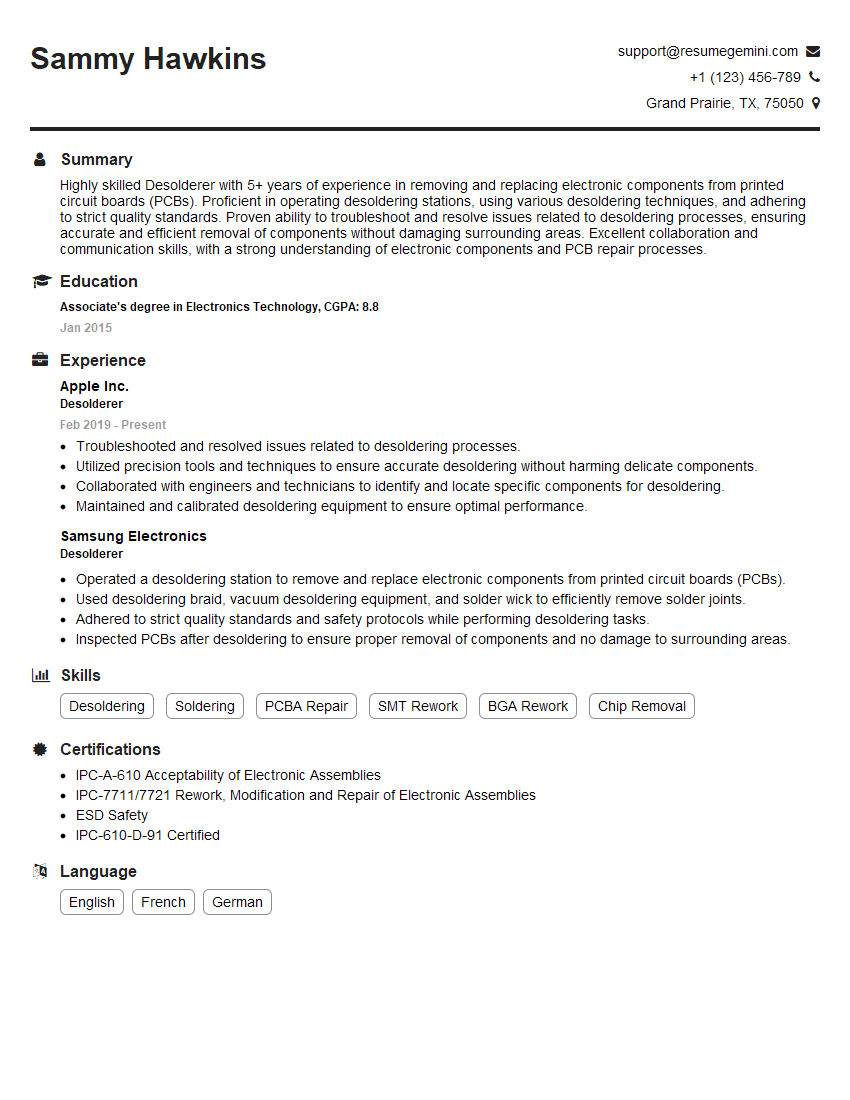

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Desolderer

1. What are the different types of desoldering methods and when should each be used?

- Manual Desoldering: This method uses a soldering iron and desoldering braid or a solder sucker to remove solder from a circuit board. It is best for small or delicate components.

- Hot Air Desoldering: This method uses a hot air gun to melt the solder and remove it from the circuit board. It is best for large or complex components.

- Vacuum Desoldering: This method uses a vacuum pump to suck up the molten solder. It is best for removing large amounts of solder from a circuit board.

2. What are the safety precautions that should be taken when desoldering?

- Use a fume extractor to remove harmful fumes from the work area.

- Wear safety glasses and gloves to protect yourself from hot solder and flying debris.

- Do not touch the heated components or the desoldering tool with bare hands.

- Allow the components and tools to cool before handling them.

3. What are the common troubleshooting tips for desoldering?

- If the solder is not melting properly, increase the temperature of the soldering iron or hot air gun.

- If the solder is not being removed properly, use a different desoldering method or flux.

- If the components are being damaged, reduce the temperature of the soldering iron or hot air gun.

- If the circuit board is being damaged, use a heat sink to protect it.

4. What are the different types of desoldering tools and what are the advantages and disadvantages of each?

- Soldering Iron: Advantages: Inexpensive, easy to use, good for small components. Disadvantages: Slow, can damage components if not used properly.

- Desoldering Braid: Advantages: Fast, easy to use, good for removing large amounts of solder. Disadvantages: Can leave residue on the circuit board.

- Solder Sucker: Advantages: Fast, easy to use, good for removing small amounts of solder. Disadvantages: Can damage components if not used properly.

- Hot Air Gun: Advantages: Fast, good for removing large or complex components. Disadvantages: Can damage components if not used properly, requires a separate air compressor.

- Vacuum Desoldering: Advantages: Fast, good for removing large amounts of solder. Disadvantages: Expensive, requires a separate vacuum pump.

5. What are the different types of solder and what are the advantages and disadvantages of each?

- Lead-based Solder: Advantages: Inexpensive, easy to use, good for most applications. Disadvantages: Contains lead, which is a hazardous material.

- Lead-free Solder: Advantages: Does not contain lead, which is a hazardous material. Disadvantages: More expensive, harder to use, may not be suitable for all applications.

6. What are the different techniques for desoldering surface mount components?

- Hot Air Method: Use a hot air gun to melt the solder and remove the component.

- Soldering Iron Method: Use a soldering iron to melt the solder and remove the component.

- Tweezers Method: Use tweezers to remove the component after the solder has been melted.

7. What are the different techniques for desoldering through-hole components?

- Soldering Iron Method: Use a soldering iron to melt the solder and remove the component.

- Desoldering Braid Method: Use desoldering braid to wick up the solder and remove the component.

- Solder Sucker Method: Use a solder sucker to suck up the solder and remove the component.

8. What are the different types of desoldering fluxes and what are the advantages and disadvantages of each?

- Rosin Flux: Advantages: Inexpensive, easy to use, good for most applications. Disadvantages: Can leave residue on the circuit board.

- No-Clean Flux: Advantages: Does not leave residue on the circuit board. Disadvantages: More expensive, harder to use, may not be suitable for all applications.

- Water-Soluble Flux: Advantages: Can be removed with water, does not leave residue on the circuit board. Disadvantages: Can corrode the circuit board if not removed properly.

9. What are the different types of desoldering stations and what are the advantages and disadvantages of each?

- Analog Desoldering Station: Advantages: Inexpensive, easy to use, good for small or infrequent desoldering jobs. Disadvantages: Not as precise as digital desoldering stations.

- Digital Desoldering Station: Advantages: More precise than analog desoldering stations, easier to use, more features. Disadvantages: More expensive than analog desoldering stations.

10. What are the different types of solder tips and what are the advantages and disadvantages of each?

- Conical Tip: Advantages: Good for general purpose desoldering. Disadvantages: Not as precise as other tip shapes.

- Chisel Tip: Advantages: Good for removing solder from large areas. Disadvantages: Not as precise as other tip shapes.

- Bevel Tip: Advantages: Good for removing solder from small areas. Disadvantages: Not as durable as other tip shapes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Desolderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Desolderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Desolderers play a crucial role in the manufacturing industry, ensuring that electronic components and circuit boards are properly connected and functioning. Their responsibilities involve:

1. Desoldering and Reworking Components

Using specialized tools, desolderers remove faulty or unwanted components from printed circuit boards (PCBs) without damaging surrounding circuitry. They also rework components, ensuring that they are correctly soldered and functioning properly.

2. Inspecting and Testing Circuit Boards

Desolderers inspect circuit boards for defects, ensuring that solder joints are secure and that components are correctly positioned. They perform electrical tests to verify the functionality of the boards and troubleshoot any issues.

3. Maintaining Equipment and Workspace

Desolderers maintain their equipment, including desoldering stations, soldering irons, and inspection tools, ensuring that they are in good working order. They also keep their workspace clean and organized.

4. Collaborating with Production Team

Desolderers work closely with the production team, communicating potential issues and ensuring that circuit boards meet quality standards. They may also provide technical support and training to other team members.

5. Documenting Procedures

Desolderers document their work, including desoldering procedures and inspection reports. This documentation ensures traceability and compliance with quality standards.

Interview Tips

Preparing for a desoldering interview requires a combination of technical knowledge, industry understanding, and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and mission. Research the industry to understand current trends and technological advancements. This knowledge will demonstrate your interest and enthusiasm for the role.

2. Practice Your Technical Skills

Review the key responsibilities of a desolderer and practice your technical skills, such as desoldering techniques, component replacement, and circuit board inspection. You may consider bringing a portfolio or examples of your work to the interview.

3. Prepare Example Answers

Prepare specific examples that demonstrate your technical abilities, problem-solving skills, and attention to detail. Use the STAR method (Situation, Task, Action, Result) to structure your answers and highlight the impact of your actions.

4. Ask Insightful Questions

Prepare thoughtful questions to ask the interviewer. This shows your engagement and interest in the role and the company. Ask about company culture, career progression opportunities, and any specific projects or challenges.

5. Dress Professionally and Be Punctual

Make a good first impression by dressing professionally and arriving on time for the interview. Maintain eye contact, speak clearly, and be respectful throughout the interview. Your demeanor and professionalism will reflect your commitment to the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Desolderer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!