Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Developing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

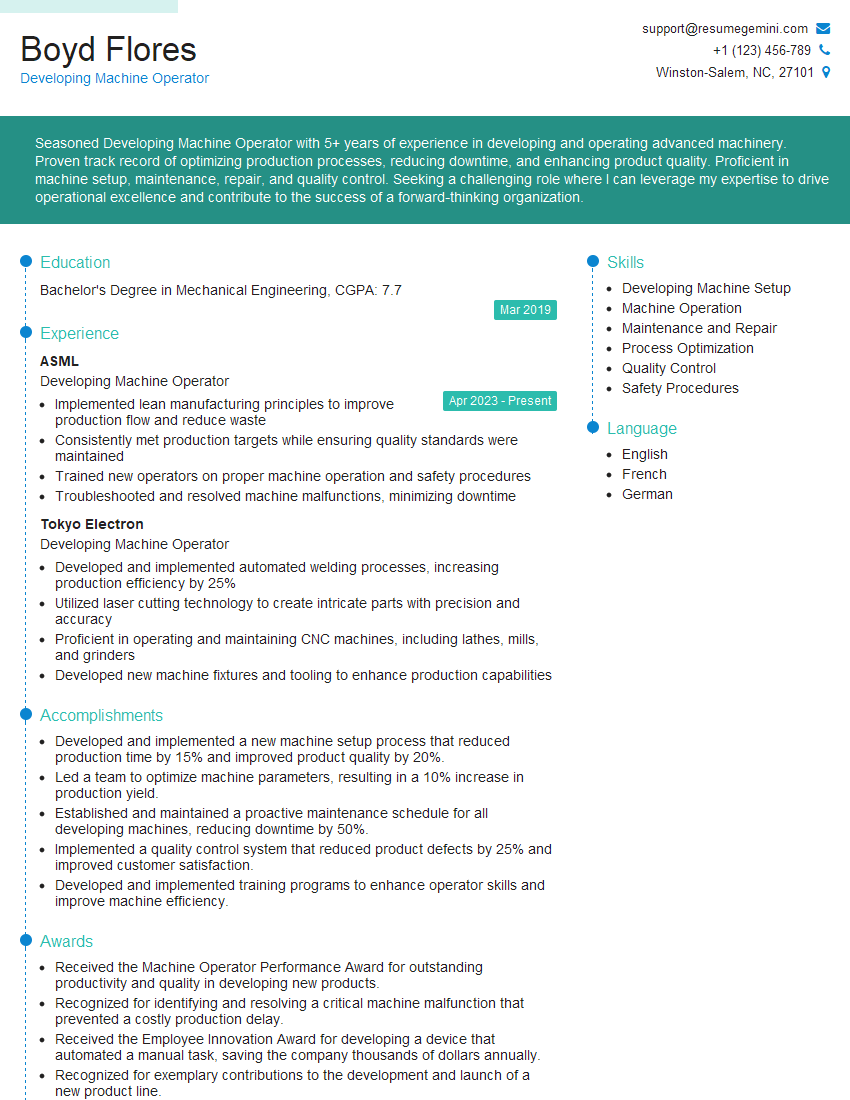

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Developing Machine Operator

1. Describe the process of setting up and operating a CNC machine?

- Mount the workpiece securely on the CNC machine’s worktable.

- Load the CNC program into the machine’s controller.

- Set the machine’s operating parameters, such as speed, feed rate, and depth of cut.

- Start the CNC program and monitor the machine’s operation.

- Make adjustments to the machine’s operating parameters as needed to ensure the desired results.

2. What are the different types of CNC machines and what are their applications?

Milling Machines

- Used for cutting and shaping metal, plastic, and wood.

- Can perform a variety of operations, such as drilling, tapping, boring, and contouring.

Turning Machines

- Used for creating cylindrical parts, such as shafts, bolts, and gears.

- Can perform a variety of operations, such as turning, facing, boring, and threading.

Grinding Machines

- Used for finishing metal parts to achieve a precise surface finish.

- Can perform a variety of operations, such as grinding, honing, and lapping.

3. What are the key factors to consider when selecting a cutting tool for a CNC machine?

- The material being cut

- The desired surface finish

- The cutting speed and feed rate

- The tool’s geometry

- The tool’s life expectancy

4. What are the different types of CNC programming languages?

- G-code

- M-code

- D-code

- NC code

- APT

5. What are the advantages of using a CNC machine over a manual machine?

- Increased accuracy and precision

- Reduced setup time

- Increased productivity

- Reduced labor costs

- Improved safety

6. What are the challenges of working with CNC machines?

- The high cost of CNC machines

- The need for skilled operators

- The complexity of CNC programming

- The potential for errors

- The need for regular maintenance

7. What are the safety precautions that must be taken when working with CNC machines?

- Wear appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Be aware of the machine’s operating area and keep clear of moving parts.

- Never operate a CNC machine while under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions for safe operation.

- Report any unsafe conditions or malfunctions to your supervisor immediately.

8. Describe the different types of maintenance that must be performed on CNC machines.

Preventive Maintenance

- Regular cleaning and lubrication

- Inspection of belts, hoses, and other components

- Replacement of worn parts

Corrective Maintenance

- Repair of broken parts

- Adjustment of machine settings

- Troubleshooting of electrical and mechanical problems

9. What are the different types of certification that are available for CNC machine operators?

- Certified CNC Machine Operator (CMO) from the National Institute for Metalworking Skills (NIMS)

- CNC Operator and Programmer from the Society of Manufacturing Engineers (SME)

- CNC Machinist from the National Tooling and Machining Association (NTMA)

10. What are the career opportunities for CNC machine operators?

- CNC machinist

- CNC programmer

- CNC setup technician

- CNC maintenance technician

- CNC quality control inspector

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Developing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Developing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Developing Machine Operators are highly skilled professionals responsible for operating and maintaining advanced manufacturing equipment. They play a crucial role in ensuring the efficient production of high-quality products.

1. Machine Operation

Operate and monitor various types of developing machines, such as coating, etching, and printing equipment.

- Adjust machine settings to optimize production parameters, including speed, temperature, and pressure.

- Monitor machine performance, identify potential issues, and take corrective actions.

2. Quality Control

Conduct regular quality inspections of produced materials to ensure they meet specifications.

- Inspect materials for defects, such as scratches, smudges, or uneven coatings.

- Calibrate and maintain measurement devices to ensure accurate quality control processes.

3. Equipment Maintenance

Perform preventive maintenance tasks to keep machines in good working condition.

- Clean, lubricate, and adjust machine components as needed.

- Troubleshoot and resolve equipment malfunctions.

4. Process Improvement

Collaborate with other team members to identify and implement process improvements.

- Analyze production data to identify areas for optimization.

- Suggest and implement modifications to equipment or processes to enhance efficiency and quality.

Interview Tips

To ace the interview for a Developing Machine Operator position, candidates should:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and culture to demonstrate your understanding of the organization and the role you are applying for.

- Review the company website, social media pages, and industry news articles.

- Identify the specific responsibilities and qualifications required for the position.

2. Practice Answering Common Interview Questions

Anticipate and prepare for common interview questions related to your skills, experience, and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and concise answers that highlight your abilities.

- Emphasize your technical expertise, problem-solving skills, and attention to detail.

3. Highlight Your Relevant Experience and Skills

Carefully review the job description and identify the specific skills and experience the employer is seeking.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Showcase your proficiency in operating and maintaining developing machines, as well as your knowledge of quality control procedures.

4. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your interest in the position and the company.

- Inquire about the company’s growth plans, industry trends, or specific projects related to developing machine operations.

- Ask about the training and development opportunities available for employees.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview and arrive on time.

- Consider wearing business attire or a smart casual outfit that conveys professionalism and respect.

- Plan your route in advance and allow plenty of time for traffic or unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Developing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!