Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Developmental Electronics Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

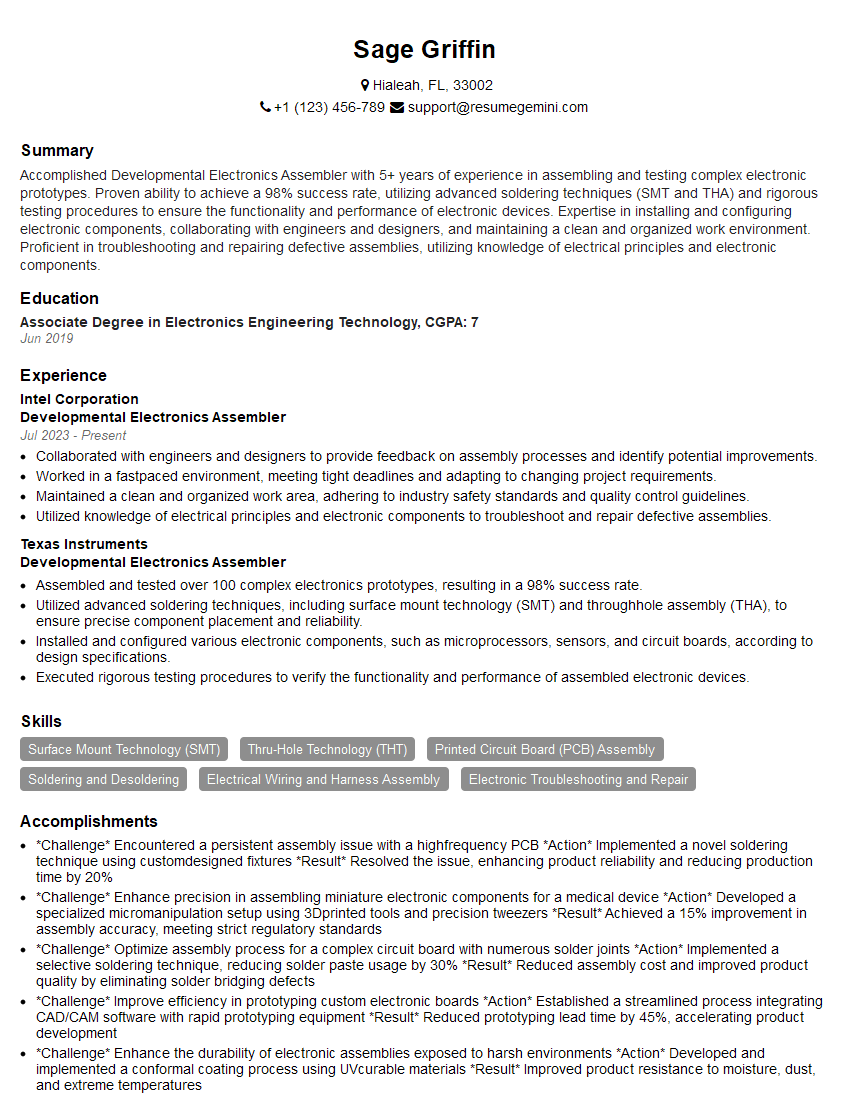

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Developmental Electronics Assembler

1. What is the difference between through-hole and surface-mount technology (SMT)?

Through-hole technology (THT) involves inserting the component leads through holes in the printed circuit board (PCB) and soldering them in place. Surface-mount technology (SMT) involves placing the components on the surface of the PCB and soldering them in place.

- THT is an older technology that is still used in some applications, such as high-power and high-voltage circuits.

- SMT is a newer technology that is more popular for high-volume, low-cost applications.

- SMT components are smaller and lighter than THT components, and they can be placed more densely on the PCB.

2. What are the different types of soldering techniques?

Hand soldering

- Hand soldering is the most common type of soldering.

- It involves using a soldering iron to melt solder and create a joint between two pieces of metal.

- Hand soldering can be used for both THT and SMT components.

Wave soldering

- Wave soldering is a mass-production soldering technique that uses a wave of molten solder to create joints between components and the PCB.

- Wave soldering is typically used for SMT components.

- Wave soldering is faster and more efficient than hand soldering, but it can also be more expensive.

Reflow soldering

- Reflow soldering is a mass-production soldering technique that uses a heated oven to melt solder and create joints between components and the PCB.

- Reflow soldering is typically used for SMT components.

- Reflow soldering is faster and more efficient than hand soldering, but it can also be more expensive.

3. What are the different types of electronic components?

- Resistors

- Capacitors

- Inductors

- Diodes

- Transistors

- Integrated circuits (ICs)

4. What are the steps involved in assembling an electronic circuit board?

- Prepare the PCB by applying solder paste to the pads where the components will be placed.

- Place the components on the PCB.

- Solder the components to the PCB.

- Inspect the circuit board to ensure that all of the components are properly soldered.

- Test the circuit board to ensure that it is functioning properly.

5. What are the different types of electronic test equipment?

- Multimeters

- Oscilloscopes

- Function generators

- Signal analyzers

- Spectrum analyzers

6. What are the safety precautions that should be taken when working with electronics?

- Wear appropriate safety gear, such as safety glasses and gloves.

- Work in a well-ventilated area.

- Use proper soldering techniques.

- Do not touch live circuits.

- Be aware of the potential for electrical shock.

7. What is the difference between a schematic diagram and a PCB layout?

A schematic diagram is a graphical representation of an electronic circuit that shows the electrical connections between the components.

A PCB layout is a physical representation of an electronic circuit that shows the placement of the components on the PCB.

8. What is the purpose of a bill of materials (BOM)?

A bill of materials (BOM) is a list of the components that are required to assemble an electronic circuit.

The BOM includes the following information:

- The name of the component

- The quantity of the component

- The value of the component

- The package type of the component

- The supplier of the component

9. What is the difference between a prototype and a production PCB?

A prototype PCB is a small-volume PCB that is used to test the design of a new electronic circuit.

A production PCB is a high-volume PCB that is used to manufacture the final product.

Prototype PCBs are typically made using a different process than production PCBs.

Prototype PCBs are typically more expensive than production PCBs.

10. What is the future of electronics assembly?

The future of electronics assembly is bright.

The demand for electronics is growing rapidly.

New technologies are being developed that are making electronics assembly faster, cheaper, and more efficient.

Electronics assembly is a critical part of the global economy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Developmental Electronics Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Developmental Electronics Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Developmental Electronics Assembler plays a vital role in the development and production of electronic devices. Key responsibilities of this role include:

1. Printed Circuit Board Assembly

Assembling and wiring printed circuit boards (PCBs) according to design specifications.

2. Component Sourcing and Material Management

Identifying and sourcing electronic components from suppliers.

3. Prototype Development and Testing

Building and testing prototypes to ensure functionality and adherence to design requirements.

4. Process Improvement and Optimization

Continuously evaluating and improving assembly processes to enhance efficiency and quality.

5. Quality Control and Assurance

Conducting inspections and tests to ensure assembled products meet quality standards.

Interview Tips

To ace an interview for a Developmental Electronics Assembler position, it’s essential to demonstrate your technical skills, attention to detail, and problem-solving abilities. Here are some key tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This shows the interviewer your interest and preparation.

2. Highlight Your Technical Skills and Experience

Clearly articulate your expertise in electronics assembly, PCB design, and component sourcing. Provide specific examples of projects you’ve worked on.

3. Showcase Your Problem-Solving Abilities

Describe instances where you encountered challenges during the assembly process and how you resolved them. This demonstrates your critical thinking and analytical skills.

4. Emphasize Attention to Detail and Quality Control

Highlight your commitment to precision and quality in your work. Share examples of how you ensure the accuracy and reliability of assembled products.

5. Prepare for Common Interview Questions

Practice answering common interview questions around your technical abilities, work experience, and motivation for the role. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

6. Demonstrate Your Adaptability and Learning Mindset

Electronics assembly is constantly evolving. Show the interviewer that you’re eager to learn new technologies and adapt to changing industry standards.

7. Ask Insightful Questions

Asking thoughtful questions about the company, the team, and the project requirements demonstrates your engagement and interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Developmental Electronics Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.