Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dial Mounter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

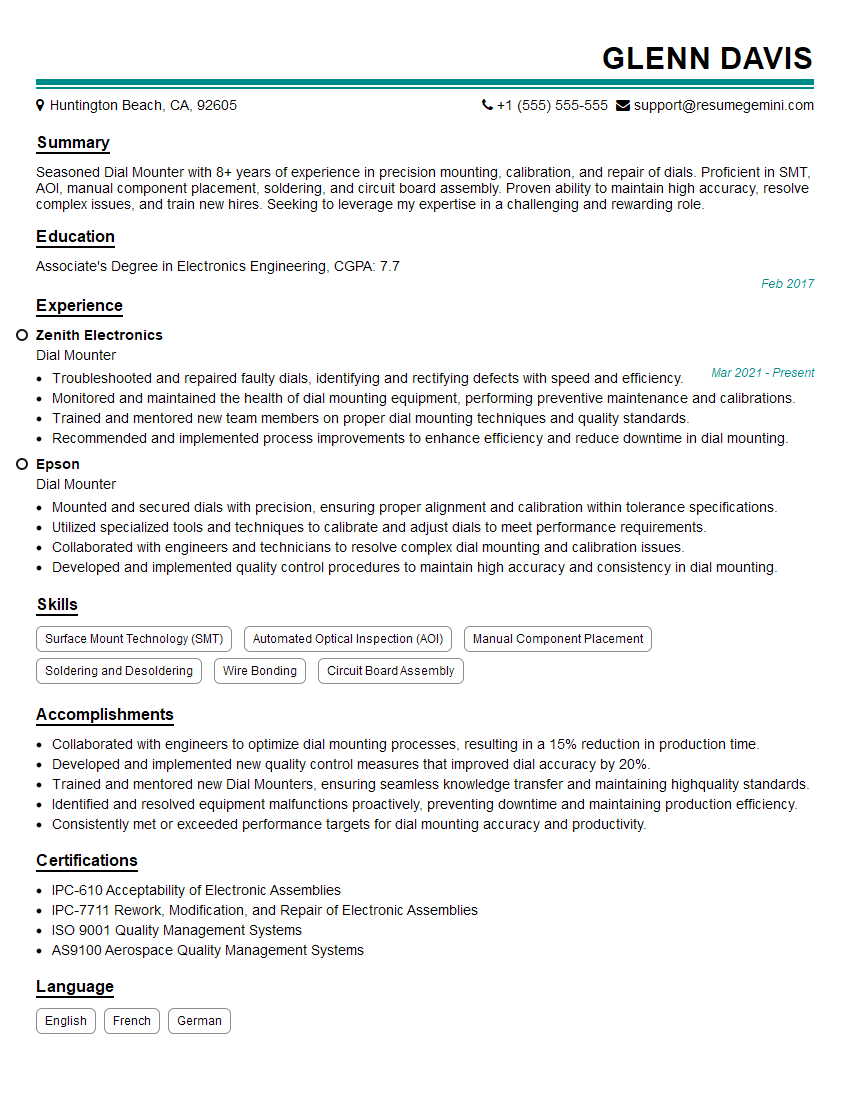

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dial Mounter

1. Explain the process of dial mounting.

The process of dial mounting involves installing a dial on a rotating shaft or spindle. It ensures that the dial is correctly aligned and securely fastened to the shaft, allowing for accurate measurements or adjustments.

- Preparation: Gather necessary tools, including a press, dial indicator, and mounting accessories.

- Shaft Preparation: Clean and prepare the shaft surface to ensure a good fit with the dial.

- Dial Selection: Choose the appropriate dial for the application, considering factors such as size, accuracy, and measurement range.

- Dial Mounting: Use a press or other mounting method to attach the dial to the shaft, ensuring proper alignment and tightness.

- Adjustment and Calibration: Adjust the dial’s zero point and calibrate it against a known standard or reference.

2. How do you ensure accuracy when mounting a dial?

Precision and Calibration:

- Use high-precision mounting tools and calibrated equipment.

- Follow recommended mounting procedures and specifications.

Alignment and Position:

- Properly align the dial with the shaft and measurement target.

- Ensure the dial is mounted perpendicular to the shaft or surface it measures.

Tightening and Stability:

- Tighten the dial securely using appropriate torque or pressure.

- Use lock nuts or other locking mechanisms to prevent loosening.

3. Describe the different types of dial mounting methods.

There are various dial mounting methods, each suitable for different applications and dial types:

- Press-fit Mounting: The dial is directly pressed onto the shaft, using pressure to create a tight fit.

- Screw-on Mounting: The dial has threaded holes that allow it to be screwed onto a threaded shaft or using a mounting adapter.

- Stud-mount Mounting: A stud is mounted on the shaft, and the dial is attached to the stud using a nut or locking mechanism.

- Flange Mounting: The dial has a flange that is bolted or secured to a flange on the shaft or mounting surface.

4. Explain the importance of proper mounting pressure when mounting a dial.

Proper mounting pressure is crucial for ensuring accuracy and maintaining the dial’s performance:

- Accuracy: Insufficient pressure can lead to slippage or misalignment, affecting measurement accuracy.

- Stability: Excessive pressure can damage the dial or shaft, compromising its stability and reliability.

- Durability: Proper mounting pressure ensures a secure and durable connection between the dial and the shaft, extending its lifespan.

5. How do you handle and store dials to ensure their accuracy and longevity?

Proper handling and storage of dials are essential for maintaining their accuracy and longevity:

- Handling: Use clean gloves or a lint-free cloth when handling dials, to avoid contamination or damage.

- Storage: Store dials in a clean, dry, and controlled environment to prevent corrosion, moisture damage, or impact.

- Protection: Use protective covers or cases to shield dials from dust, dirt, and external factors.

- Calibration: Regularly calibrate dials according to manufacturer’s specifications or industry standards to ensure their accuracy.

6. What tools and equipment are essential for mounting and maintaining dials?

Various tools and equipment are necessary for mounting and maintaining dials:

- Dial Mounter: A specialized press or tool used to mount dials on shafts.

- Dial Indicator: For precise measurements and adjustments during dial mounting and calibration.

- Mounting Accessories: Adapters, spacers, and other accessories to facilitate mounting dials on various shafts.

- Calibration Equipment: Precision measuring tools, such as gauge blocks or a master dial, for calibrating dials.

- Protective Gear: Safety glasses and gloves to protect the operator during mounting and handling.

7. Explain how to troubleshoot and resolve common issues related to dial mounting.

Troubleshooting common issues in dial mounting involves identifying the source of the problem and applying appropriate solutions:

- Loose Dial: Check mounting pressure, retighten the dial, or use an anti-seize compound.

- Incorrect Alignment: Realign the dial using a dial indicator or other precision measuring tools.

- Measurement Inaccuracy: Calibrate the dial against a known standard or seek professional repair.

- Damage: Inspect the dial and shaft for damage, replace or repair if necessary.

- Corrosion or Rust: Clean and lubricate the dial and shaft, apply anti-corrosion measures.

8. Describe the safety precautions that should be followed when mounting dials.

Safety precautions are crucial when mounting dials to prevent injuries or damage:

- Eye Protection: Wear safety glasses to protect eyes from flying debris or other hazards.

- Hand Protection: Use gloves to prevent cuts or abrasions during handling and mounting.

- Proper Mounting: Ensure the dial is securely mounted to prevent slippage or falling.

- Guarding: Use guards or shields to protect operators from moving parts or rotating shafts.

- Training: Train personnel on proper dial mounting techniques and safety procedures.

9. What is the difference between a dial indicator and a dial mounter?

A dial indicator is a precision measuring instrument used to measure small displacements or variations, while a dial mounter is a specialized tool used to mount dials securely on shafts or spindles:

- Function: Dial indicators measure deviations or displacement, whereas dial mounters facilitate the stable and accurate mounting of dials.

- Accuracy: Dial indicators are highly accurate instruments, typically used for precise measurements, while dial mounters prioritize secure and proper mounting.

- Application: Dial indicators are used in various applications, including engineering, manufacturing, and quality control, while dial mounters are primarily used in the mounting process.

10. Describe how you would train a new employee on the proper techniques for dial mounting.

Training a new employee on dial mounting techniques involves a step-by-step approach:

- Introduction: Explain the purpose and importance of dial mounting, safety precautions, and equipment used.

- Demonstration: Demonstrate the proper techniques for mounting dials, including shaft preparation, dial selection, and mounting procedures.

- Hands-on Practice: Provide the employee with guided practice on mounting dials, allowing them to develop confidence and proficiency.

- Troubleshooting: Discuss common issues that may arise during dial mounting and provide solutions for troubleshooting and resolving them.

- Calibration and Maintenance: Explain the importance of dial calibration and maintenance, and demonstrate proper procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dial Mounter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dial Mounter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Mount dials on watch movements

Dial Mounters are responsible for mounting dials onto watch movements. The dial is the face of the watch, and it contains the hour markers, minute markers, and other information. The movement is the internal mechanism of the watch, and it powers the hands and other parts. To mount the dial, the Dial Mounter must carefully align it with the movement and then secure it in place. This is a delicate and precise operation, as any misalignment could cause the watch to malfunction.

2. Ensure that dials are properly aligned and centered

After mounting the dial, the Dial Mounter must ensure that it is properly aligned and centered. This is done by using a variety of tools, including a magnifier, tweezers, and a dial indicator. The Dial Mounter must also check the dial for any defects, such as scratches or chips. If any defects are found, the dial must be replaced.

3. Perform quality control checks on dials

Dial Mounters are also responsible for performing quality control checks on dials. This includes checking the dial for any defects, such as scratches or chips. The Dial Mounter must also check the dial to ensure that it is properly aligned and centered. If any defects are found, the dial must be replaced.

4. Troubleshoot and resolve issues with dials

Dial Mounters may also be responsible for troubleshooting and resolving issues with dials. This may include fixing dials that are not properly aligned or centered, or replacing dials that are damaged. Dial Mounters must be able to diagnose problems quickly and efficiently, and they must be able to work independently.

Interview Tips

1. Research the company and the position

Before going on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to learn more about the specific responsibilities of the Dial Mounter position. You can research the company online, or you can contact the company directly to request more information.

2. Practice answering common interview questions

There are a number of common interview questions that you may be asked during an interview for a Dial Mounter position. These questions may include:

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with mounting dials on watch movements?

- How do you ensure that dials are properly aligned and centered?

- What are some of the challenges you have faced in your previous role as a Dial Mounter?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed. If you are not sure what to wear, you can always contact the company directly to ask about their dress code.

4. Be on time for your interview

Punctuality is important, so make sure that you arrive for your interview on time. If you are running late, be sure to call or email the company to let them know. You should also give yourself plenty of time to get to the interview location, so that you are not stressed or rushed.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and open, and let the interviewer see your personality. This will help the interviewer to determine if you are a good fit for the Dial Mounter position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dial Mounter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!