Feeling lost in a sea of interview questions? Landed that dream interview for Dial-Screw Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dial-Screw Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

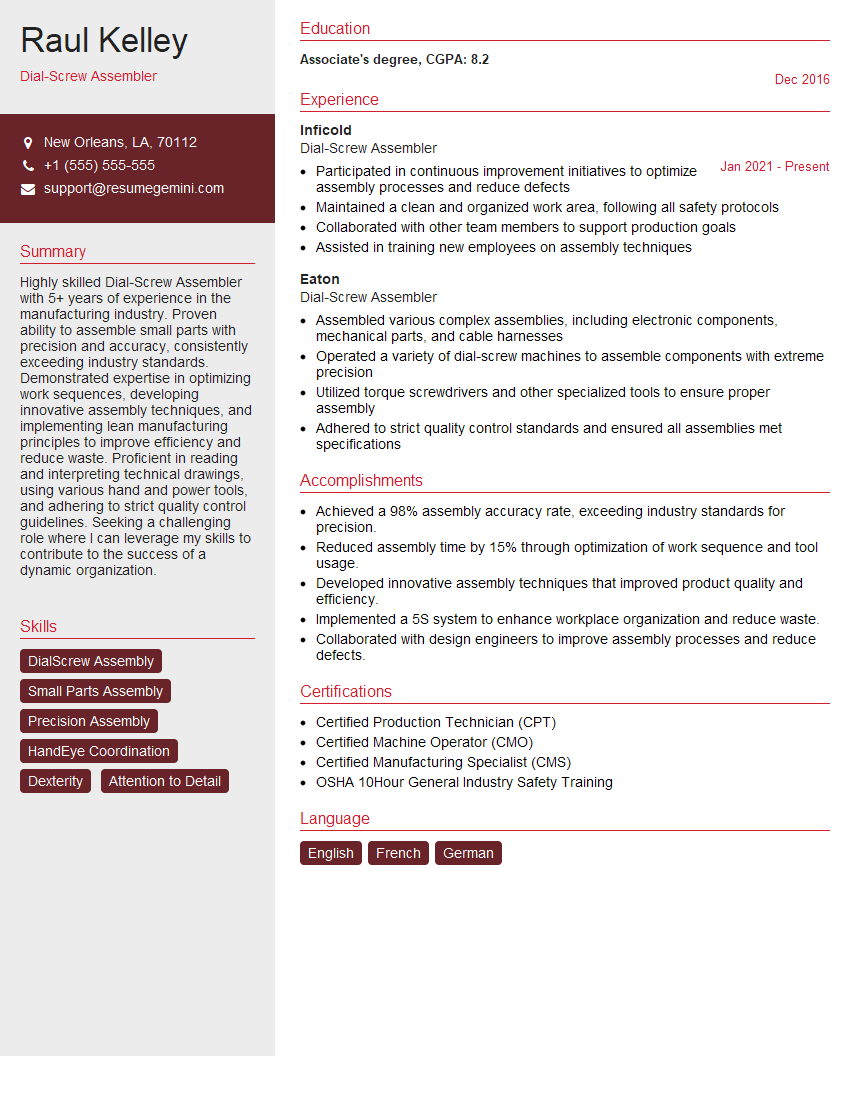

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dial-Screw Assembler

1. What is the standard torque value for assembling 16 mm screws and 20 mm screws?

- For 16 mm screws, the standard torque value is between 7.0 and 8.5 Newton-meters.

- For 20 mm screws, the standard torque value is between 10.0 and 12.0 Newton-meters.

2. Can you describe the process of assembling a screw to a dial using a hand tool?

Using a Dial-Screw Assembler Tool

- Position the dial over the screw.

- Align the dial-screw assembler over the screw and dial.

- Apply force downward and start spinning clockwise to tighten the screw in place.

- Once the screw is adequately tightened, release the downward force and continue spinning clockwise until the dial is properly seated.

Using a Pliers/Hex Key

- Hold the dial in place over the screw.

- Manually turn the screw clockwise using the pliers/hex key until adequately tightened.

- Ensure the dial is properly seated.

3. What is the approximate cycle time expected to assemble 10 dials?

- Assuming an average assembly time of 10 seconds per dial, the approximate cycle time to assemble 10 dials would be 100 seconds.

- This is an approximate value and may vary depending on factors such as the complexity of the assembly, the skill of the assembler, and the availability of tools and materials.

4. How do you ensure that the screws are tightened to the correct torque?

- Use a torque screwdriver or torque wrench to apply the correct amount of torque to the screws.

- Follow the manufacturer’s specifications for the torque value of the screws being used.

- Calibrate the torque tool regularly to ensure its accuracy.

5. What are some common defects that can occur during dial-screw assembly?

- Loose screws: Screws that are not tightened to the correct torque can come loose, causing the dial to shift or fall off.

- Stripped screws: Screws that are overtightened can strip, making it difficult to remove them later.

- Damaged dials: Dials can be damaged if they are not properly aligned before the screws are tightened.

- Cross-threading: Screws that are not started straight can cross-thread, making it difficult to tighten them properly.

6. How do you troubleshoot a dial-screw assembly that is not functioning properly?

- Check if the screws are loose or stripped.

- Check if the dial is damaged.

- Check if the screws are cross-threaded.

- Check if the torque tool is calibrated correctly.

7. What are the safety precautions that should be taken when working with a dial-screw assembly machine?

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from sharp edges.

- Keep your hair and clothing away from moving parts.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

8. How do you maintain a dial-screw assembly machine?

- Clean the machine regularly to remove dust and debris.

- Lubricate the moving parts regularly.

- Inspect the machine regularly for signs of wear or damage.

- Calibrate the torque tool regularly.

9. What is your experience with working with dial-screw assembly machines?

- I have been working with dial-screw assembly machines for the past 5 years.

- I am familiar with all aspects of operating and maintaining these machines.

- I have a proven track record of meeting production targets and maintaining high quality standards.

10. Why are you interested in working as a Dial-Screw Assembler at our company?

- I am interested in working as a Dial-Screw Assembler at your company because I am confident that I have the skills and experience that you are looking for.

- I am a hard worker and I am always willing to learn new things.

- I am also a team player and I am always willing to help out my colleagues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dial-Screw Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dial-Screw Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dial-Screw Assembler is responsible for assembling parts using a dial-screw machine. They must be able to follow instructions, work independently, and have a good attention to detail. Key job responsibilities include:

1. Assemble parts using a dial-screw machine

This involves placing parts into the machine, operating the machine, and removing the finished product. The assembler must be able to follow instructions and work independently.

2. Inspect finished products for quality

The assembler must be able to identify and correct any defects in the finished product. They must also be able to follow quality control procedures.

3. Maintain the dial-screw machine

The assembler must be able to clean and lubricate the machine, and make minor repairs. They must also be able to identify and report any major problems with the machine.

4. Follow safety procedures

The assembler must be able to follow all safety procedures, including wearing appropriate safety gear and using the machine safely.

Interview Tips

Here are some tips on how to ace an interview for a Dial-Screw Assembler position:

1. Research the company and the position

This will help you to understand the company’s culture and the specific requirements of the position. You can find information on the company’s website and in industry publications.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in a clear and concise manner.

3. Dress professionally

This will show the interviewer that you are serious about the position and that you respect the company.

4. Be on time for your interview

This is a sign of respect for the interviewer’s time.

5. Be confident and enthusiastic

This will show the interviewer that you are excited about the opportunity to work for the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dial-Screw Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!