Are you gearing up for an interview for a Diamond Blender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Diamond Blender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

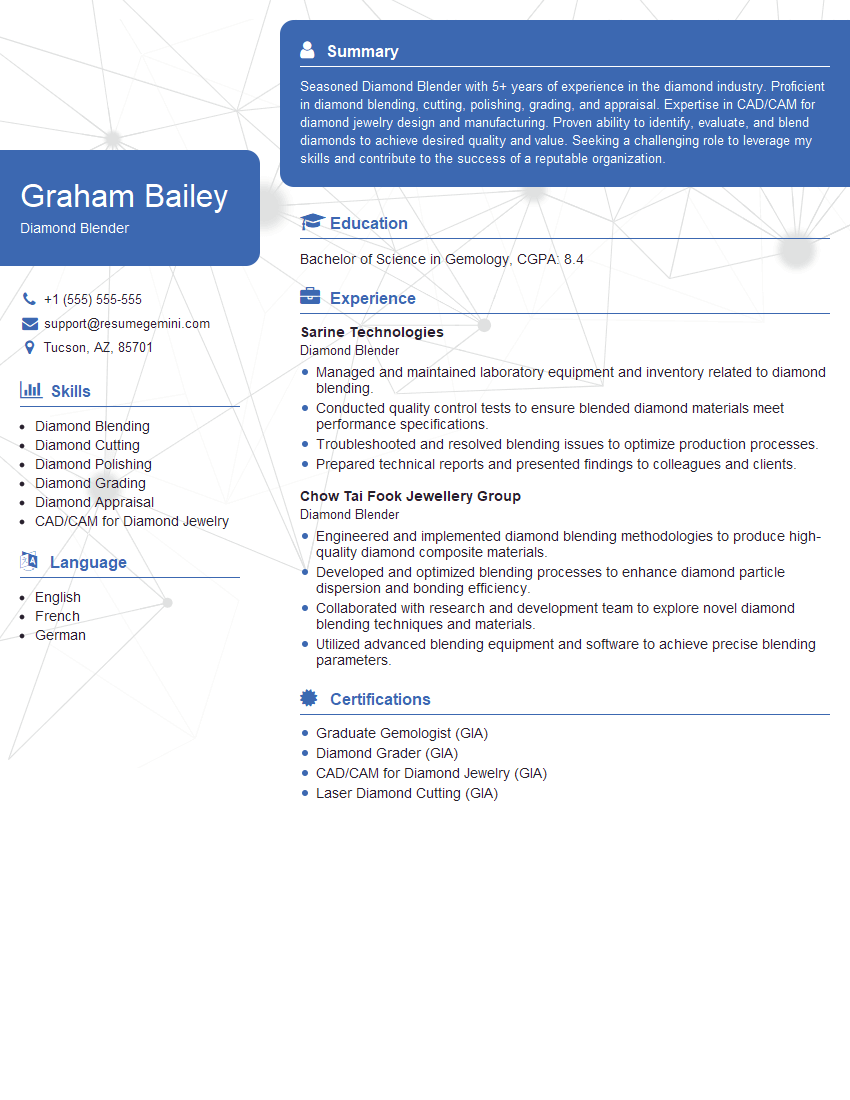

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diamond Blender

1. Which techniques do you use to ensure the diamonds are blended evenly and consistently?

- Describe the specific blending techniques used, such as sequential blending, multi-step blending, or ultrasonic blending.

- Explain the role of equipment calibration and maintenance in maintaining blend consistency.

- Mention any quality control measures implemented to monitor and verify blend uniformity.

2. How do you handle variations in diamond size and shape during the blending process?

Maintaining Blend Uniformity

- Explain strategies for accommodating different diamond sizes, such as using multiple sieves or adjusting blending parameters.

- Describe how you ensure that diamonds are blended according to the desired size distribution.

Preventing Damage to Diamonds

- Discuss techniques used to minimize diamond breakage or chipping during blending.

- Explain the importance of selecting appropriate blending equipment and settings.

3. What methods do you use to calibrate and maintain the blending equipment?

- Describe the calibration procedures used to ensure accurate blending ratios.

- Explain the maintenance schedule and techniques implemented to keep equipment in optimal condition.

- Mention any industry standards or guidelines followed for equipment calibration and maintenance.

4. How do you handle and prevent contamination during the diamond blending process?

- Describe the cleanroom environment and protocols followed to minimize contamination.

- Explain the use of specialized equipment or techniques, such as electrostatic discharge protection.

- Discuss the procedures for cleaning and sterilizing equipment and materials.

5. How do you manage the waste generated during the diamond blending process?

- Describe the waste segregation and disposal practices followed.

- Explain the measures taken to minimize environmental impact.

- Discuss any recycling or reuse initiatives implemented.

6. What safety precautions do you take when working with diamond powders?

- Describe the personal protective equipment (PPE) used, such as respirators and gloves.

- Explain the ventilation and exhaust systems implemented to control dust and fumes.

- Discuss emergency procedures and spill containment measures.

7. How do you stay updated on the latest diamond blending technologies and industry best practices?

- Describe your involvement in industry conferences, workshops, or training programs.

- Explain how you access and evaluate technical literature and research.

- Discuss your role in implementing new technologies or improving existing processes.

8. What challenges have you faced in your previous diamond blending experience and how did you overcome them?

- Describe specific challenges encountered, such as achieving precise blending ratios or preventing diamond breakage.

- Explain the problem-solving strategies employed and the outcomes achieved.

- Discuss how the lessons learned have improved your blending skills.

9. How do you measure and ensure the quality of the blended diamond powders?

- Describe the quality control tests performed, such as particle size analysis, shape analysis, and purity evaluation.

- Explain the use of industry standards or specifications for quality assurance.

- Discuss the role of statistical process control (SPC) in monitoring and maintaining product quality.

10. What is your understanding of the different types of diamond blending methods and their applications?

- Describe the advantages and disadvantages of various methods, such as mechanical blending, ultrasonic blending, and chemical blending.

- Explain the selection criteria for choosing the appropriate blending method for specific applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diamond Blender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diamond Blender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diamond Blenders operate under the guidance of supervisors and are responsible for blending and mixing industrial diamond abrasives with other materials to create diamond tools. They are also involved in the maintenance and calibration of machinery and equipment used in the blending process.

1. Blending and Mixing

Diamond Blenders are responsible for the blending and mixing of diamond abrasives with different materials, such as metals, ceramics, and polymers, to create diamond tools.

- Follow established blending and mixing procedures.

- Select and measure the appropriate proportions of diamond abrasives and other materials.

- Operate blending and mixing equipment to ensure proper mixing and dispersion of materials.

2. Machine and Equipment Maintenance

Diamond Blenders are responsible for maintaining and calibrating the machinery and equipment used in the blending process, as well as ensuring that it is operating properly.

- Inspect and clean blending and mixing equipment regularly.

- Calibrate and adjust equipment to ensure accurate measurements and mixing.

- Perform minor repairs and maintenance tasks on equipment as needed.

3. Quality Control

Diamond Blenders are responsible for conducting quality control checks on the blended and mixed materials to ensure that they meet specifications.

- Perform visual inspections and dimensional measurements of blended materials.

- Conduct testing to verify the properties and characteristics of blended materials.

- Maintain records of quality control checks and results.

4. Other Responsibilities

Diamond Blenders may also be responsible for a range of other tasks, such as:

- Assisting with the development and improvement of blending and mixing processes.

- Training new employees on blending and mixing procedures.

- Working with engineers and scientists to develop new diamond tool formulations.

Interview Tips

Preparing for an interview for a Diamond Blender position requires thorough understanding of the job responsibilities and industry knowledge, as well as effective communication and presentation skills.

1. Research the Company and Position

Research the company’s background, products or services, and industry reputation. This will help you understand the company’s culture and the specific requirements of the Diamond Blender position.

- Visit the company website and read company literature.

- Look for news articles or industry publications that mention the company.

- Reach out to your network or use LinkedIn to connect with current or former employees of the company.

2. Practice Your Answers to Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- Tailor your answers to the specific job requirements.

- Use the STAR method (Situation, Task, Action, Result) to provide concrete examples of your skills and experience.

- Practice your answers out loud to ensure they are clear and concise.

3. Highlight Your Relevant Experience and Skills

Emphasize your relevant experience and skills in your resume and during the interview. Quantify your accomplishments whenever possible, using specific numbers or metrics.

- Review the job description carefully and identify the key skills and experience required.

- Highlight your experience in blending and mixing diamond abrasives or related materials.

- Describe your skills in maintaining and calibrating machinery and equipment.

4. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the position and the industry. Show that you are eager to learn and contribute to the company. Maintain a professional demeanor throughout the interview.

- Arrive on time for the interview and dress appropriately.

- Make eye contact with the interviewer and speak clearly and confidently.

- Ask thoughtful questions about the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Diamond Blender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.