Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Diamond Die Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

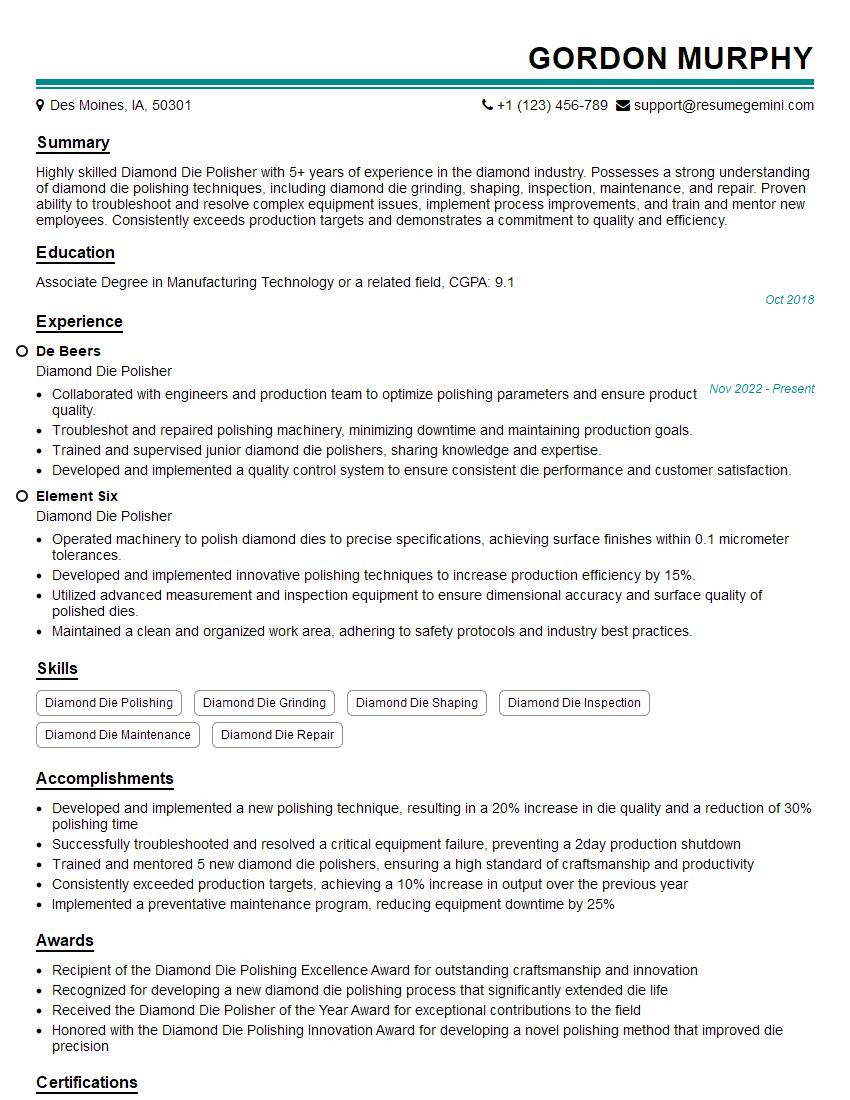

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diamond Die Polisher

1. What are the steps involved in polishing diamond dies?

- Prepare the die by cleaning and degreasing it.

- Mount the die on the polishing machine.

- Select the appropriate polishing wheel and abrasive compound.

- Start the machine and apply the abrasive compound to the die.

- Polish the die until the desired surface finish is achieved.

- Remove the die from the machine and clean it.

2. What are the different types of polishing wheels used for diamond dies?

Natural diamond wheels

- Made from natural diamond crystals bonded to a metal matrix.

- Very hard and durable, but also expensive.

Synthetic diamond wheels

- Made from synthetic diamond crystals bonded to a metal matrix.

- Less expensive than natural diamond wheels, but also less durable.

CBN (cubic boron nitride) wheels

- Made from CBN crystals bonded to a metal matrix.

- Harder and more durable than diamond wheels, but also more expensive.

3. What are the different types of abrasive compounds used for polishing diamond dies?

- Diamond powder

- CBN powder

- Boron carbide powder

- Silicon carbide powder

4. What are the factors that affect the surface finish of a polished diamond die?

- The type of polishing wheel used

- The type of abrasive compound used

- The speed of the polishing machine

- The pressure applied to the die

- The duration of the polishing process

5. How do you measure the surface finish of a polished diamond die?

- Using a surface profilometer

- Using an optical microscope

- Using a scanning electron microscope (SEM)

6. What are the common defects that can occur during the polishing of diamond dies?

- Scratches

- Chips

- Cracks

- Pits

- Buildup of abrasive compound

7. How do you prevent defects from occurring during the polishing of diamond dies?

- Using the correct polishing wheel and abrasive compound

- Using the correct speed and pressure

- Polishing for the correct duration

- Cleaning the die regularly

- Inspecting the die regularly for defects

8. What are the safety precautions that should be taken when polishing diamond dies?

- Wear gloves and safety glasses

- Use a dust mask

- Use a polishing machine that is in good working condition

- Inspect the die regularly for defects

- Be aware of the machine’s moving parts

9. How do you maintain a diamond polishing machine?

- Clean the machine regularly

- Inspect the machine for wear and tear

- Lubricate the machine regularly

- Calibrate the machine regularly

- Follow the manufacturer’s instructions for maintenance

10. What are the different applications of polished diamond dies?

- In the manufacture of wire

- In the manufacture of optical fiber

- In the manufacture of medical devices

- In the manufacture of electronic components

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diamond Die Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diamond Die Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diamond Die Polisher holds a pivotal role in the manufacturing industry, tasked with the meticulous creation of diamond dies utilized in wire drawing operations. These skilled professionals possess an array of responsibilities that demand technical expertise, attention to detail, and a commitment to precision.

1. Diamond Die Preparation

The foundation of flawless die polishing lies in meticulous preparation. Diamond Die Polishers meticulously select, inspect, and configure diamond dies, ensuring their suitability for the intended wire drawing process.

2. Die Polishing Techniques

Leveraging specialized equipment and advanced polishing techniques, Diamond Die Polishers carefully refine the surface of diamond dies. They employ controlled pressure, precise movements, and appropriate abrasives to achieve the desired finish and dimensional accuracy.

3. Quality Control and Inspection

To guarantee the highest quality standards, Diamond Die Polishers perform rigorous inspections throughout the polishing process. They employ optical and dimensional measuring instruments to evaluate surface roughness, shape, and other critical parameters, ensuring compliance with specifications.

4. Maintenance and Troubleshooting

To maintain optimal performance, Diamond Die Polishers proactively service and troubleshoot polishing equipment. They conduct routine inspections, identify potential issues, and promptly address any malfunctions, minimizing downtime and ensuring seamless production.

Interview Tips

Securing the role of a Diamond Die Polisher demands thorough preparation. Candidates should delve into the following tips to enhance their interview performance.

1. Research and Industry Knowledge

Demonstrate a deep understanding of the diamond die polishing process, the industry’s best practices, and the latest technological advancements. Research the specific company and their products to tailor your responses accordingly.

2. Showcase Technical Expertise

Highlight your proficiency in die preparation, polishing techniques, and quality control procedures. Provide specific examples of your accomplishments, quantifying your contributions whenever possible to showcase your impact.

3. Emphasize Precision and Detail Orientation

Emphasize your meticulous nature, unwavering focus on precision, and ability to produce consistently high-quality results. Describe situations where you successfully achieved exceptional accuracy and met or exceeded specifications.

4. Troubleshoot and Problem-Solve

Prepare for questions that assess your troubleshooting and problem-solving abilities. Describe instances where you identified and resolved equipment malfunctions, process inefficiencies, or quality issues.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Diamond Die Polisher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.