Are you gearing up for an interview for a Diamond Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Diamond Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

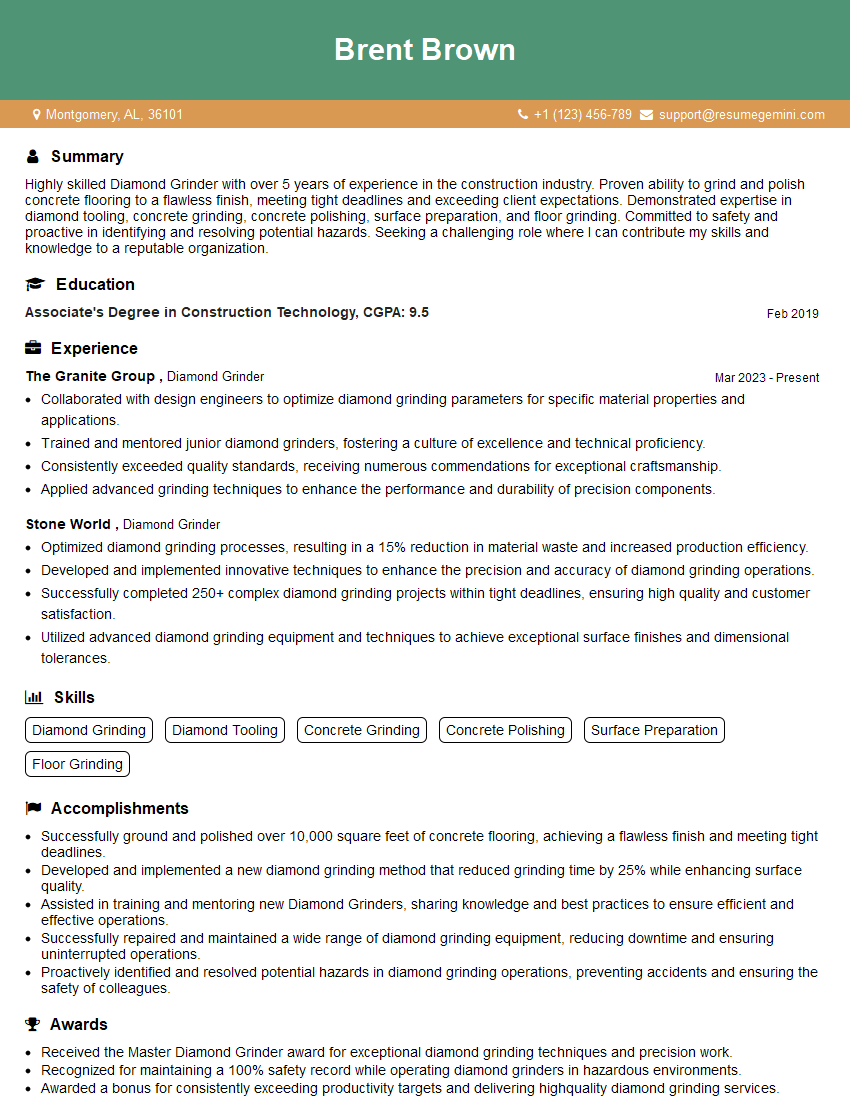

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diamond Grinder

1. How would you determine the appropriate diamond grit size for a specific grinding application?

To determine the appropriate diamond grit size for a specific grinding application, I would consider the following factors:

- The hardness of the material being ground

- The desired surface finish

- The required grinding efficiency

- The type of grinding machine being used

2. What are the different types of diamond grinding wheels, and when should each type be used?

Metal Bond Wheels

- Used for grinding hard materials such as carbide, hardened steel, and glass.

- Provide a high grinding ratio and long wheel life.

Resin Bond Wheels

- Used for grinding softer materials such as non-ferrous metals, ceramics, and plastics.

- Offer a smooth surface finish and low grinding forces.

Electroplated Wheels

- Used for precision grinding and shaping operations.

- Provide a very fine surface finish.

3. How do you ensure that a diamond grinding wheel is properly balanced before use?

To ensure that a diamond grinding wheel is properly balanced before use, I would follow these steps:

- Mount the wheel on a balancing stand.

- Rotate the wheel at operating speed.

- Use a dial indicator or other balancing device to identify any imbalances.

- Add or remove weight from the wheel as necessary to achieve a balanced condition.

4. What safety precautions should be taken when operating a diamond grinder?

When operating a diamond grinder, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including eye protection, hearing protection, and a dust mask.

- Ensure that the grinder is properly grounded and that all electrical connections are secure.

- Secure the workpiece properly to prevent it from moving during grinding.

- Use a sharp diamond wheel and apply appropriate force to avoid wheel breakage.

- Never exceed the maximum operating speed of the grinder.

5. How do you troubleshoot a diamond grinder that is not performing optimally?

If a diamond grinder is not performing optimally, I would troubleshoot the issue by checking the following:

- The sharpness of the diamond wheel

- The balance of the wheel

- The alignment of the wheel

- The speed of the grinder

- The workpiece securement

- The presence of any foreign objects or debris

6. What techniques can be used to achieve a specific surface finish when grinding with diamonds?

To achieve a specific surface finish when grinding with diamonds, I would use the following techniques:

- Selecting the appropriate diamond grit size

- Adjusting the grinding speed and feed rate

- Using a lubricant or coolant

- Dressing the grinding wheel regularly

7. How do you maintain and store diamond grinding wheels to ensure their longevity?

To maintain and store diamond grinding wheels to ensure their longevity, I would follow these practices:

- Store the wheels in a dry, climate-controlled environment.

- Protect the wheels from physical damage, such as impacts or moisture.

- Clean the wheels regularly to remove any grinding debris or contamination.

- Dress the wheels periodically to maintain their shape and sharpness.

8. What are the advantages of using diamond grinding wheels over other types of grinding wheels?

Diamond grinding wheels offer several advantages over other types of grinding wheels, including:

- Exceptional hardness and durability

- High grinding efficiency and low wheel wear

- Ability to grind a wide range of materials

- Long lifespan and low maintenance requirements

- Precision and accuracy in grinding operations

9. How do you calculate the grinding ratio of a diamond grinding wheel?

To calculate the grinding ratio of a diamond grinding wheel, I would use the following formula:

- Grinding Ratio = (Volume of Material Removed) / (Volume of Wheel Wear)

10. What factors influence the selection of a diamond grinding wheel for a specific application?

When selecting a diamond grinding wheel for a specific application, I would consider the following factors:

- The type of material being ground

- The desired surface finish

- The grinding machine being used

- The operating conditions, such as speed and feed rate

- The cost and availability of the wheel

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diamond Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diamond Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diamond Grinders are skilled professionals responsible for the precision shaping and finishing of various materials using diamond-coated grinding wheels. They play a crucial role in diverse industries, including construction, manufacturing, and engineering. Key job responsibilities of a Diamond Grinder encompass:

1. Grinding and Polishing

Diamond Grinders operate specialized machines to grind and polish concrete, stone, metal, and other materials. They use diamond-coated grinding wheels to remove excess material, smooth surfaces, and refine edges.

2. Surface Preparation

Prior to grinding, Diamond Grinders prepare surfaces by removing paint, coatings, and other contaminants. They ensure smooth and even surfaces for optimal grinding results.

3. Template and Layout Interpretation

Diamond Grinders interpret technical drawings and templates to determine grinding patterns and dimensions. They plan and lay out the sequence of cuts to achieve precise results.

4. Equipment Maintenance and Calibration

Diamond Grinders maintain and calibrate grinding equipment, including diamond wheels, machines, and accessories. They ensure that equipment is functioning properly and calibrated for accurate grinding.

5. Safety Compliance

Diamond Grinders prioritize safety by adhering to industry regulations and safety protocols. They wear appropriate protective gear and take necessary precautions to prevent accidents and injuries.

6. Quality Control

Diamond Grinders inspect and verify the quality of their work. They ensure that the finished product meets specifications and industry standards.

7. Collaboration and Communication

Diamond Grinders work in collaboration with other professionals, such as project managers and architects. They communicate effectively to ensure that all project requirements are met.

Interview Tips

To ace an interview for the position of Diamond Grinder, it is essential to prepare thoroughly and showcase your skills and experience. Here are some interview preparation tips and hacks:

1. Research the Company and Position

Familiarize yourself with the company’s profile, industry, and the specific requirements of the Diamond Grinder position. This knowledge will enable you to tailor your answers and demonstrate your understanding of the role.

2. Highlight Relevant Skills and Experience

Emphasize your experience in grinding and polishing various materials, along with your knowledge of diamond-coated grinding wheels. Quantify your accomplishments whenever possible to demonstrate your impact and value.

3. Prepare for Technical Questions

Be prepared to answer questions about grinding techniques, equipment calibration, and safety protocols. Study industry standards and best practices to enhance your credibility.

4. Showcase Safety Awareness

Highlight your commitment to safety by demonstrating your understanding of industry regulations and your adherence to safety practices. Employers prioritize the well-being of their employees, so emphasizing your safety consciousness will be a valuable asset.

5. Practice Common Interview Questions

Practice answering common interview questions such as “Why are you interested in this role?” and “Tell me about yourself.” Prepare concise and compelling responses that highlight your qualifications and enthusiasm.

6. Be Enthusiastic and Professional

Convey your enthusiasm for the position and the industry. Ask thoughtful questions to show your engagement and interest. Maintain a professional demeanor throughout the interview and dress appropriately.

7. Follow Up

After the interview, send a thank-you note to the interviewer. Express your appreciation for their time and reiterate your interest in the position. A well-written thank-you note can leave a positive lasting impression.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Diamond Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Diamond Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.