Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Die Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

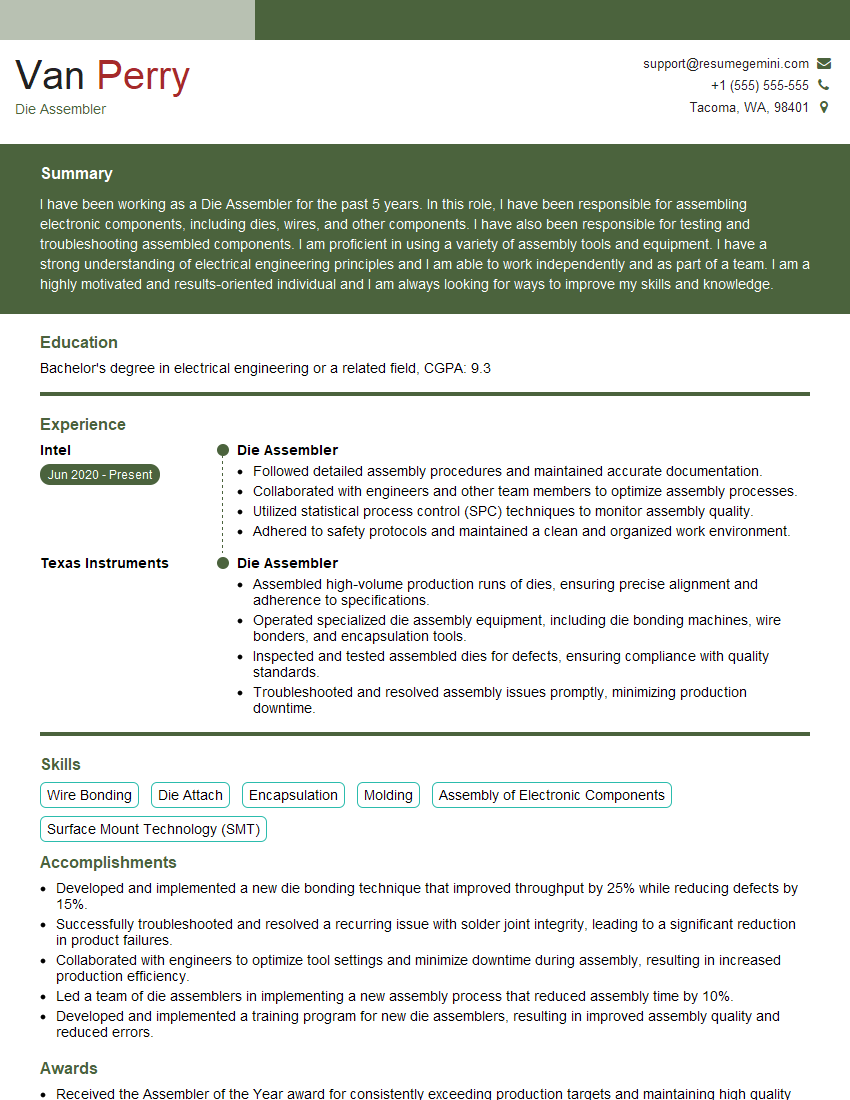

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Assembler

1. Explain the process of die assembly?

The process of die assembly involves several key steps:

- Die Preparation: The die is first prepared by cleaning and applying a thin layer of adhesive.

- Wire Bonding: Tiny gold wires are used to connect the die to the lead frame, which provides electrical connections.

- Molding: The die and lead frame are placed in a mold, and epoxy resin is injected to encapsulate and protect the assembly.

- Trimming and Inspection: The molded assembly is trimmed to remove excess material, and then inspected to ensure proper connections and functionality.

- Testing: The assembled die is thoroughly tested to verify its electrical and performance characteristics.

2. What are the different types of die assembly techniques?

Wire Bonding

- Ball Bonding: A wire is heated and formed into a ball, which is then attached to the die and lead frame.

- Thermocompression Bonding: A heated tool is used to apply pressure and create a bond between the wire and the die/lead frame.

Tape Automated Bonding (TAB)

- A thin, flexible tape with pre-patterned gold conductors is used to connect the die to the lead frame.

3. What are the critical factors to consider when choosing a die assembly technique?

When selecting a die assembly technique, the following factors should be considered:

- Die Size and Complexity: The size and complexity of the die can influence the choice of technique.

- Electrical Requirements: The electrical requirements, such as current and voltage, can impact the selection of bonding method.

- Reliability and Yield: Different techniques offer varying levels of reliability and yield, which can affect the overall cost and quality of the assembly.

- Cost: The cost of materials and equipment associated with each technique should be taken into consideration.

4. What equipment is used in die assembly?

Die assembly typically involves the use of the following equipment:

- Bonding Machine: A machine used to perform wire bonding or other bonding techniques.

- Molding Press: A machine that applies pressure to the assembly during the molding process.

- Trimming Machine: A machine that removes excess material from the molded assembly.

- Inspection Equipment: Optical microscopes, electrical testers, and other tools used to inspect the assembled die.

5. What are the quality control measures used in die assembly?

To ensure the quality and reliability of die assemblies, the following quality control measures are typically implemented:

- Visual Inspection: Microscopic inspection of the assembly to detect any defects or inconsistencies.

- Electrical Testing: Testing of the electrical connections and functionality of the assembly.

- Environmental Testing: Testing of the assembly under various environmental conditions, such as temperature extremes and vibration.

- Statistical Process Control (SPC): Monitoring and analyzing process parameters to identify and eliminate potential defects.

6. What are the common defects that can occur in die assembly?

Some common defects that can occur in die assembly include:

- Bonding Defects: Improper bonding of the die to the lead frame, causing electrical failures.

- Molding Defects: Voids or cracks in the epoxy molding material, which can compromise the assembly’s integrity.

- Trimming Defects: Damage or misalignment of the assembly during the trimming process.

- Handling Defects: Damage or contamination of the assembly during handling or storage.

7. How do you troubleshoot and resolve die assembly defects?

To troubleshoot and resolve die assembly defects, the following steps can be taken:

- Identify the Defect: Inspect the assembly visually and electrically to identify the type of defect.

- Determine the Cause: Analyze the process and materials used to identify the root cause of the defect.

- Implement Corrective Measures: Modify the process or materials to eliminate the defect.

- Verify the Fix: Conduct additional inspections and testing to ensure that the defect has been resolved.

8. What are the recent advancements in die assembly technology?

Die assembly technology is constantly evolving to improve efficiency and quality. Some recent advancements include:

- Automated Die Bonding: Automated machines that perform wire bonding with high precision and speed.

- Advanced Bonding Techniques: New bonding methods, such as ultrasonic bonding, that offer improved reliability and performance.

- Nano-Scale Assembly: Techniques for assembling dies at the nanoscale, enabling the development of advanced electronic devices.

9. What are the career opportunities for Die Assemblers?

Die Assemblers can pursue careers in various industries, including:

- Semiconductor Manufacturing: Assembling dies for integrated circuits (ICs) and microprocessors.

- Electronics Manufacturing: Assembling dies for electronic devices, such as smartphones, laptops, and medical equipment.

- Automotive Industry: Assembling dies for automotive electronics, such as sensors and control modules.

- Research and Development: Developing and improving die assembly techniques and materials.

10. What are the professional organizations and certifications related to Die Assembly?

There are several professional organizations and certifications available to Die Assemblers, including:

- IEEE (Institute of Electrical and Electronics Engineers): Offers certifications in electronics manufacturing, including die assembly.

- IPC (Institute for Printed Circuits): Provides certification programs for various aspects of printed circuit board (PCB) assembly, including die assembly.

- SAE International (Society of Automotive Engineers): Offers certifications in automotive electronics, including die assembly for automotive applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Assemblers are responsible for assembling dies and fixtures used in stamping, cutting, forming, and other production processes. They read and interpret blueprints, set up and operate assembly machines, and ensure that the assembled dies meet the required specifications. Key job responsibilities include:

1. Assembly

Assembling dies and fixtures according to blueprints and specifications.

- Selecting and fitting components, such as die blocks, punches, and inserts.

- Aligning and securing components using precision tools and instruments.

2. Inspection and Testing

Inspecting and testing assembled dies to ensure they meet specifications.

- Using gauges, micrometers, and other measuring tools to verify dimensions and tolerances.

- Conducting functional tests to ensure proper operation.

3. Maintenance and Repair

Maintaining and repairing dies and fixtures to ensure optimal performance.

- Replacing worn or damaged components.

- Adjusting and calibrating dies to maintain accuracy.

4. Quality Control

Ensuring that assembled dies meet quality standards.

- Following established quality control procedures.

- Documenting assembly and inspection results.

Interview Tips

To ace an interview for a Die Assembler position, it is crucial to prepare thoroughly and demonstrate your skills and knowledge. Here are a few tips and hacks:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will give you a good understanding of the company’s industry, culture, and the responsibilities and expectations of the Die Assembler position.

2. Practice Your Answers

Prepare and practice your answers to common interview questions. This will help you feel more confident and organized during the actual interview. Focus on highlighting your skills, experience, and how you can contribute to the company.

3. Showcase Your Technical Skills

Die Assemblers need strong technical skills. During the interview, be prepared to discuss your experience with blueprint reading, assembly techniques, and quality control procedures. You can also mention any relevant certifications or training you have.

4. Emphasize Your Attention to Detail

Attention to detail is crucial for Die Assemblers. In the interview, emphasize your ability to work meticulously and follow instructions precisely. Provide examples of your work that demonstrate your accuracy and focus on quality.

5. Ask Questions

Asking thoughtful questions during the interview shows that you are engaged and interested in the role. Prepare a few questions about the company, the position, or the industry. This also gives you the opportunity to clarify any aspects of the job that you are unsure about.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!