Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Die Attacher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Die Attacher so you can tailor your answers to impress potential employers.

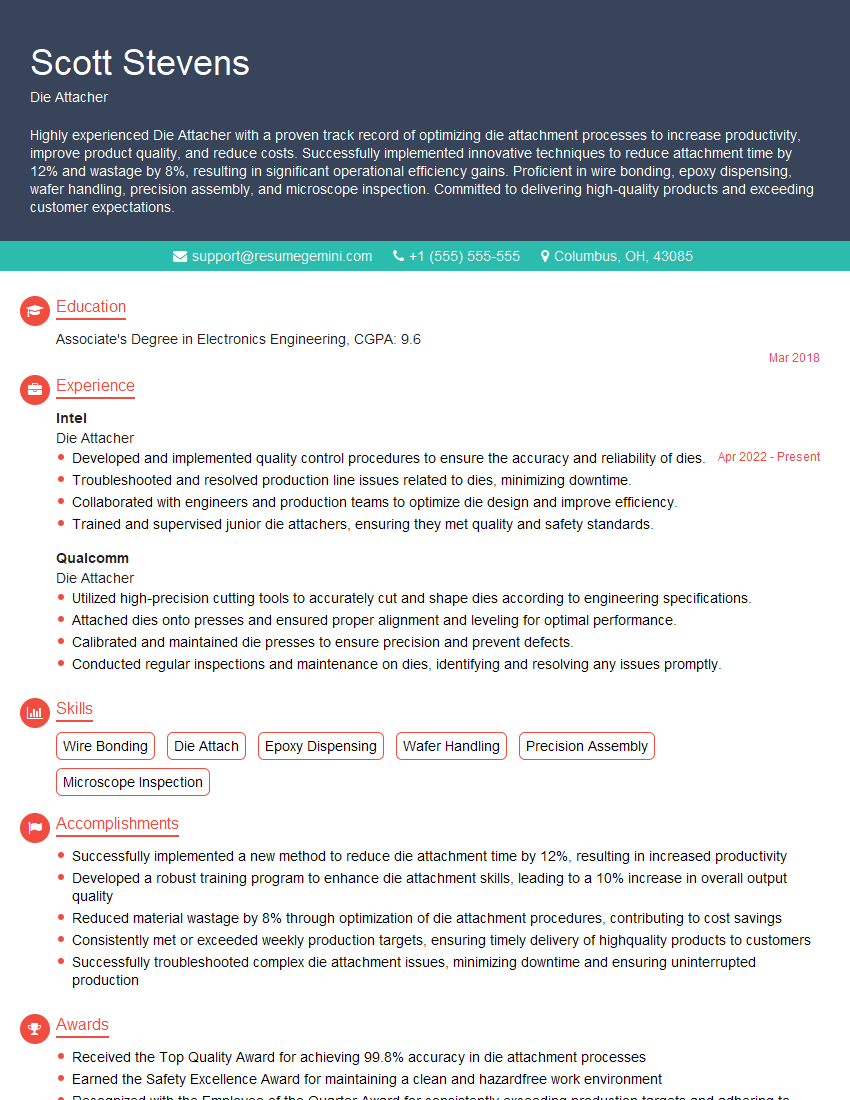

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Attacher

1. Describe the process of attaching dies to a press?

The process of attaching dies to a press involves several steps to ensure proper alignment, accuracy, and safety.

- Preparation: Gather necessary tools (wrenches, gauges, etc.), clean and inspect die surfaces.

- Die Placement: Position the lower die on the press bed, align it using spacers and gauges.

- Upper Die Mounting: Place the upper die on the ram assembly, ensuring correct orientation and alignment.

- Bolting and Tightening: Secure the dies using bolts and washers, tightening them to the specified torque.

- Alignment Verification: Use a dial indicator to check and adjust die alignment until it meets acceptable tolerances.

- Safety Checks: Inspect all bolts, connections, and guarding devices to ensure secure and hazard-free operation.

2. What are the different types of dies used in press operations?

Metal Stamping Dies

- Blanking Dies: Cut out specific shapes from metal sheets.

- Piercing Dies: Create holes or slots in metal.

- Bending Dies: Shape metal into bends or angles.

- Forming Dies: Create complex shapes by deforming metal.

Other Types

- Progressive Dies: Perform multiple operations in a single press stroke.

- Compound Dies: Combine multiple stamping operations into one die set.

- Transfer Dies: Transfer blanks between press stations for further processing.

3. Explain the importance of proper die alignment?

Proper die alignment is critical for:

- Product Quality: Ensuring accurate part dimensions, tolerances, and surface finish.

- Safety: Preventing misalignment-related accidents, such as die crashes or broken parts.

- Tool Life: Reducing wear and tear on dies, extending their lifespan.

- Press Protection: Minimizing stress and damage to the press by evenly distributing forces.

- Production Efficiency: Reducing downtime caused by misalignment issues, leading to increased productivity.

4. What are the common troubleshooting techniques for die attachment issues?

Common troubleshooting techniques include:

- Inspecting Bolts and Connections: Tightening loose bolts, replacing damaged bolts or washers.

- Checking Die Alignment: Using a dial indicator to verify alignment and make adjustments if necessary.

- Examining Die Surfaces: Inspecting for damage, burrs, or wear that could affect alignment.

- Analyzing Press Settings: Checking stroke length, tonnage, and speed for optimal die performance.

- Consulting Manufacturer’s Documentation: Referring to technical manuals for specific troubleshooting guidelines.

5. How do you handle adjustments to die height?

Die height adjustments are made using shims or spacer plates:

- Shims: Thin metal sheets placed under the die to raise its height.

- Spacer Plates: Thicker metal plates inserted between the die and the press platen.

- Step-by-Step Process: Measure the required adjustment, select appropriate shims or spacers, and insert them in the correct location.

- Alignment Verification: After adjustments, use a dial indicator to ensure proper die alignment.

6. What is your experience with using different types of press brakes?

Highlight your experience with press brakes of various capacities, tonnages, and styles:

- Mechanical Press Brakes: Using manual or motorized clutches.

- Hydraulic Press Brakes: Utilizing hydraulic cylinders for bending operations.

- CNC Press Brakes: Advanced machines with computer-controlled bending processes.

- Special Purpose Press Brakes: Designed for specific bending applications.

7. How do you ensure the safety of personnel and equipment when working with dies?

Safety measures include:

- Proper Training: Ensuring all operators are trained and certified in die attachment procedures.

- Regular Maintenance: Inspecting and servicing dies, presses, and equipment regularly.

- Safe Work Practices: Following established safety protocols, including lockout/tagout procedures.

- Personal Protective Equipment: Wearing safety glasses, gloves, and other necessary protective gear.

- Emergency Procedures: Familiarizing yourself with emergency response protocols in case of accidents.

8. Explain the role of die lubrication in the die attachment process.

Die lubrication minimizes friction and wear:

- Reduced Die Damage: Lubrication prevents galling, seizing, and premature wear of die surfaces.

- Improved Part Quality: Reduces surface imperfections and improves the overall quality of stamped parts.

- Increased Tool Life: Lubrication extends the lifespan of dies, reducing maintenance costs.

- Types of Lubricants: Various lubricants used include oils, greases, and waxes, selected based on die material and application.

9. Describe the use of guide pins and bushings in die alignment.

Guide pins and bushings ensure precise die alignment:

- Guide Pins: Dowel-like pins that fit into matching bushings, guiding the upper and lower dies into proper alignment.

- Bushings: Precision-machined holes in die sets that guide and support guide pins.

- Accurate Alignment: Guide pins and bushings ensure that dies are properly centered and aligned, reducing the risk of misalignment.

- Wear Resistance: Made of hardened materials, guide pins and bushings resist wear and maintain alignment accuracy over time.

10. How do you calculate the required tonnage for a press brake operation?

Tonnage calculation for press brakes involves considering:

- Material Thickness: Thickness of the metal being bent.

- Material Strength: Tensile strength of the metal.

- Die Opening: Distance between the upper and lower dies.

- Bending Angle: Angle to which the metal is being bent.

- Safety Factor: Additional tonnage added for safety margin.

Formula: Tonnage = (Material Thickness x Material Strength x Die Opening x Bending Angle x Safety Factor) / 12

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Attacher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Attacher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Die Attacher plays a crucial role in manufacturing processes by accurately attaching dies to punch presses, ensuring proper functioning and preventing production delays. Their key job responsibilities include:

1. Die Attachment and Setup

Attaching and aligning dies to punch presses, ensuring proper alignment and precision.

- Inspecting dies for defects and ensuring their compatibility with the press.

- Calculating and setting up proper clearances between dies to prevent damage.

2. Press Operation and Monitoring

Operating punch presses and monitoring production processes.

- Adjusting press settings to optimize production efficiency and quality.

- Monitoring presses for any irregularities or potential issues.

3. Die Maintenance and Troubleshooting

Maintaining dies and troubleshooting any production problems.

- Inspecting dies for wear and tear, and making necessary repairs or adjustments.

- Diagnosing and resolving production issues related to die setup or press operation.

4. Safety and Compliance

Adhering to safety protocols and maintaining a safe work environment.

- Wearing appropriate safety gear and following established safety procedures.

- Maintaining a clean and organized work area, free from potential hazards.

Interview Tips

Preparing thoroughly for an interview is key to making a positive impression and showcasing your qualifications. Here are some tips to help you ace your Die Attacher interview:

1. Research the Company and Industry

Demonstrate your interest and understanding of the company and the industry by researching their website, news articles, and social media profiles. This knowledge will help you answer questions thoughtfully and show that you are genuinely interested in the position.

- Research the company’s products, services, and target market.

- Identify industry trends and challenges relevant to the position.

2. Highlight Your Skills and Experience

Tailor your resume and interview answers to emphasize the skills and experience that align with the key job responsibilities. Use specific examples to demonstrate your abilities and how you have contributed to previous roles.

- Quantify your accomplishments whenever possible, using numbers and metrics.

- Prepare examples of successful die attachment and setup procedures.

3. Prepare for Technical Questions

Expect technical questions related to die attachment, press operation, and troubleshooting. Practice answering these questions clearly and concisely, using industry-specific terminology.

- Review the basics of die attachment and punch press operation.

- Prepare answers to common troubleshooting scenarios.

4. Emphasize Safety and Compliance

Safety is paramount in manufacturing environments. Highlight your commitment to safety and compliance by discussing your experience with safety protocols and industry best practices.

- Describe your experiences with risk assessment and hazard identification.

- Explain how you ensure that dies are properly maintained and inspected.

Next Step:

Now that you’re armed with the knowledge of Die Attacher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Die Attacher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini