Are you gearing up for a career in Die Cast Die Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Die Cast Die Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

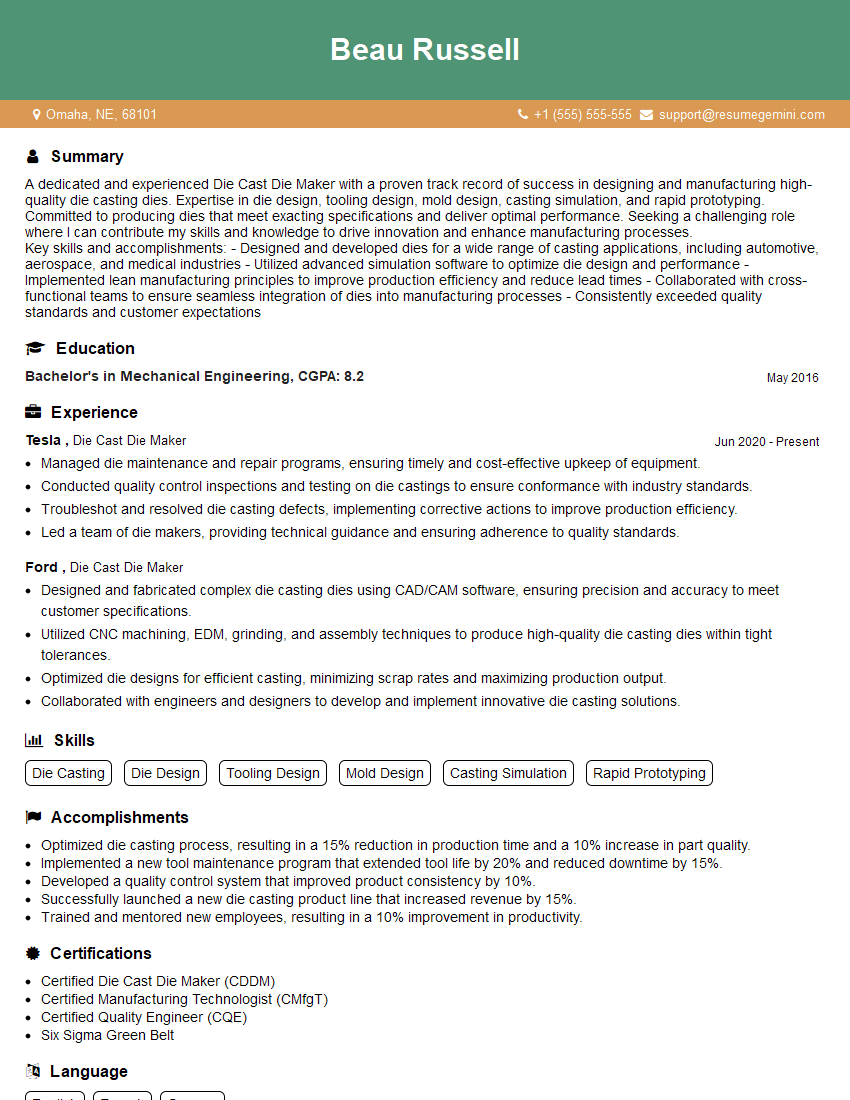

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Cast Die Maker

1. What are the different types of die casting processes?

- High-Pressure Die Casting

- Low-Pressure Die Casting

- Gravity Die Casting

- Centrifugal Die Casting

- Vacuum Die Casting

2. What are the factors that affect the quality of die castings?

Raw Materials

- Composition of the molten metal

- Purity of the molten metal

- Temperature of the molten metal

Die Design

- Shape and size of the die cavity

- Material of the die

- Surface finish of the die

Die Casting Process

- Injection pressure

- Injection speed

- Cooling rate

3. What are the common defects in die castings?

- Porosity

- Cold shuts

- Shrinkage cavities

- Gas holes

- Surface defects

4. How do you troubleshoot die casting defects?

- Identify the type of defect

- Determine the cause of the defect

- Implement corrective actions

- Monitor the results of corrective actions

5. What are the safety precautions that must be taken when working with die casting machines?

- Wear proper protective clothing

- Keep work area clean and free of debris

- Never operate a die casting machine without proper training

- Follow all safety procedures

6. What is the purpose of a sprue?

- To provide a passage for the molten metal to enter the die cavity

- To control the flow of the molten metal

- To help remove air from the die cavity

7. What is the difference between a runner and a gate?

8. What is the importance of die lubrication?

- Reduces friction between the molten metal and the die

- Prevents the molten metal from sticking to the die

- Improves the surface finish of the die castings

- Extends the life of the die

9. What is the difference between a cold chamber and a hot chamber die casting machine?

- Cold chamber die casting machines melt the metal in a separate furnace

- Hot chamber die casting machines melt the metal in the die casting machine itself

10. What are the advantages of die casting over other casting processes?

- High production rates

- Close tolerances

- Good surface finish

- Complex shapes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Cast Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Cast Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Die Cast Die Maker is responsible for making dies, which are used to shape metal in the die casting process. The job requires a high level of skill and precision, as dies must be made to exact specifications in order to produce quality castings.

1. Create and maintain dies

Die Cast Die Makers use a variety of tools and equipment to create and maintain dies. They may use computer-aided design (CAD) software to create 3D models of dies, and then use CNC machines to cut the dies from metal. They may also use hand tools to finish the dies and ensure that they meet specifications.

- Use CAD software to create 3D models of dies

- Use CNC machines to cut dies from metal

- Use hand tools to finish dies and ensure they meet specifications

2. Inspect and test dies

Once dies are created, Die Cast Die Makers must inspect and test them to ensure that they meet specifications. They may use a variety of tools and equipment to inspect dies, such as calipers, micrometers, and gauges. They may also test dies by casting metal into them and inspecting the resulting castings.

- Use calipers, micrometers, and gauges to inspect dies

- Test dies by casting metal into them and inspecting the resulting castings

3. Maintain and repair dies

Dies can wear out over time, so Die Cast Die Makers must maintain and repair them regularly. They may use a variety of tools and equipment to maintain dies, such as grinders, files, and wrenches. They may also need to replace worn or damaged parts on dies.

- Use grinders, files, and wrenches to maintain dies

- Replace worn or damaged parts on dies

4. Work with other team members

Die Cast Die Makers often work with other team members, such as engineers, machinists, and quality control inspectors. They must be able to communicate effectively with others and work as part of a team to ensure that dies are made to specifications and that castings meet quality standards.

- Communicate effectively with other team members

- Work as part of a team to ensure that dies are made to specifications and that castings meet quality standards

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few interview tips for Die Cast Die Makers:

1. Research the company and the position

Before you go on an interview, it’s important to do your research. Learn as much as you can about the company, the position you’re applying for, and the industry. This will help you answer questions intelligently and show that you’re genuinely interested in the opportunity.

- Visit the company’s website

- Read articles about the company and the industry

- Talk to people who work for the company, if possible

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer behavioral interview questions

- Practice answering questions about your skills and experience

- Be prepared to talk about your career goals

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you’re respectful of the interviewer’s time and that you’re serious about the opportunity.

- Wear a suit or business casual attire

- Arrive on time, or even a few minutes early

- Be polite and respectful to the interviewer

4. Be enthusiastic and ask questions

Interviews are a two-way street, so don’t be afraid to ask questions. This shows that you’re engaged in the conversation and that you’re interested in learning more about the company and the position. It’s also a good way to get more information that can help you make a decision about whether or not the job is a good fit for you.

- Ask questions about the company, the position, and the industry

- Be enthusiastic and engaged in the conversation

- Thank the interviewer for their time

Next Step:

Now that you’re armed with the knowledge of Die Cast Die Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Die Cast Die Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini