Are you gearing up for a career in Die Casting Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Die Casting Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

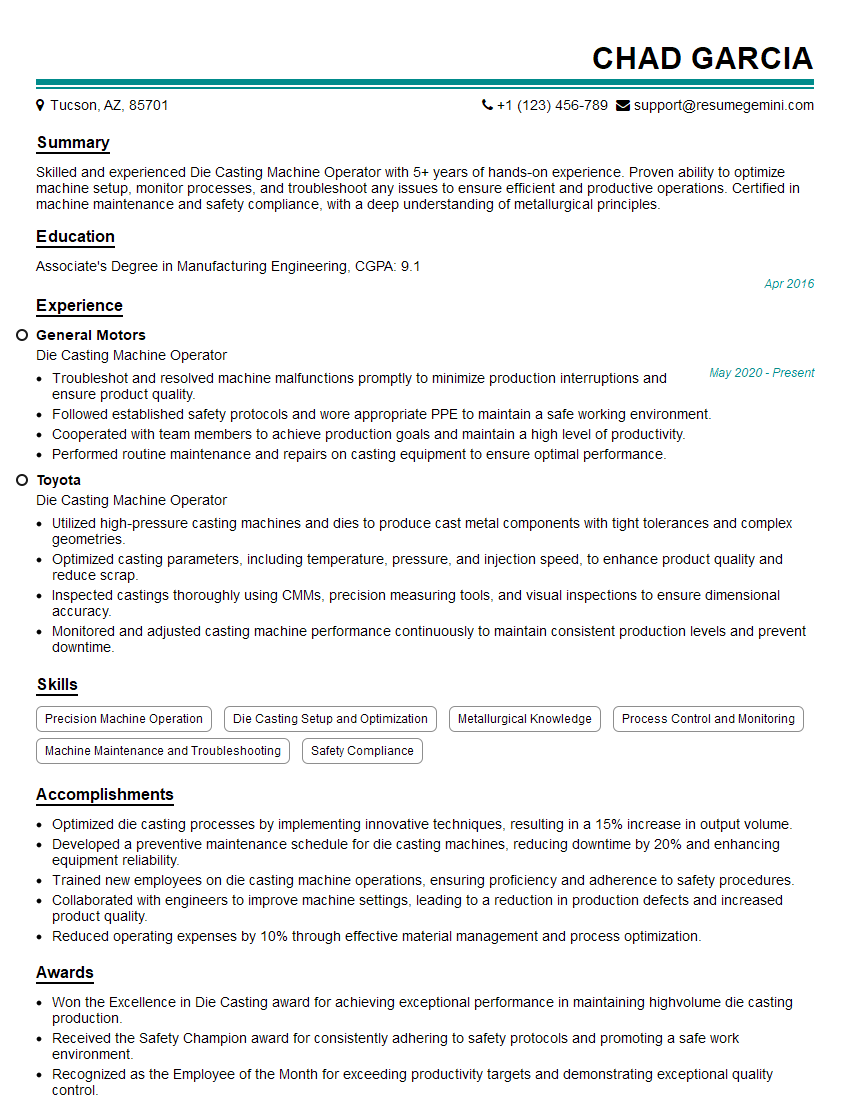

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Casting Machine Operator

1. Explain the process of die casting?

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined to the desired shape of the casting. The molten metal is forced into the mold cavity under high pressure, typically between 10,000 and 100,000 psi. The high pressure ensures that the molten metal completely fills the mold cavity and that the casting has a high degree of dimensional accuracy and surface finish.

2. What are the different types of die casting machines?

- Cold chamber machines

- Hot chamber machines

Cold chamber machines

- In cold chamber machines, the molten metal is held in a separate furnace and is ladled into the injection chamber of the machine.

- The injection chamber is then sealed and the molten metal is forced into the mold cavity under high pressure.

Hot chamber machines

- In hot chamber machines, the molten metal is held in a reservoir that is directly connected to the injection chamber.

- The molten metal is forced into the mold cavity under high pressure by a plunger.

3. What are the advantages and disadvantages of die casting?

Advantages of die casting

- High dimensional accuracy and surface finish

- Thin wall sections

- Complex shapes

- High production rates

Disadvantages of die casting

- High tooling costs

- Limited to non-ferrous metals

- Porosity

4. What are the different types of die casting defects?

- Misruns

- Cold shuts

- Porosity

- Shrinkage

- Cracking

5. How can die casting defects be prevented?

- Proper die design

- Correct injection pressure

- Optimal injection speed

- Proper melt temperature

- Adequate cooling

6. What are the safety precautions that must be followed when operating a die casting machine?

- Wear appropriate personal protective equipment

- Keep the work area clean and free of debris

- Be aware of the location of the emergency stop button

- Never operate the machine if it is not in good working condition

- Follow all manufacturer’s instructions

7. What are the maintenance procedures that must be performed on a die casting machine?

- Regularly clean the machine

- Inspect the dies for wear and tear

- Lubricate the moving parts

- Check the hydraulic system for leaks

- Calibrate the machine

8. What are the different types of die casting materials?

- Aluminum

- Zinc

- Magnesium

- Copper

- Nickel

9. What are the different applications of die casting?

- Automotive

- Aerospace

- Electronics

- Medical

- Consumer products

10. What is the future of die casting?

The future of die casting is bright. The demand for die cast products is expected to grow in the coming years. This growth is being driven by the increasing use of die cast products in various industries, such as the automotive, aerospace, and electronics industries. Die casting is a versatile process that can be used to produce a wide variety of products. As the technology continues to improve, die casting will become even more cost-effective and efficient.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Casting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Casting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Casting Machine Operators play a crucial role in the manufacturing process by operating and maintaining die casting machines to produce metal castings. Their key job responsibilities include:

1. Machine Operation

Setting up and operating die casting machines according to established procedures.

- Ensuring proper alignment of dies, cores, and casting components.

- Monitoring machine parameters such as temperature, pressure, and speed to optimize casting quality.

2. Casting Production

Producing high-quality metal castings by controlling the flow of molten metal into the die cavity.

- Adjusting machine settings to obtain desired casting dimensions and specifications.

- Identifying and correcting casting defects to minimize scrap.

3. Machine Maintenance

Performing preventive maintenance tasks to ensure optimal machine performance.

- Inspecting, cleaning, and lubricating machine components.

- Replacing worn or damaged parts.

4. Safety and Quality Control

Adhering to safety regulations and maintaining a clean and organized work area.

- Following established safety protocols for handling molten metal and operating machinery.

- Performing quality checks on castings and reporting any non-conformances.

Interview Preparation Tips

Preparing effectively for a Die Casting Machine Operator interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Job

Thoroughly research the company you are applying to, including its history, products, and industry. This will demonstrate your interest in the role and the organization.

- Review the job description carefully and identify the key skills and responsibilities required.

- Prepare specific examples from your previous experience that align with these requirements.

2. Practice Your Answers

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

- Emphasize your relevant skills, experience, and how they can benefit the company.

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role.

- Prepare questions about the company’s growth plans, industry trends, or the specific challenges of the position.

- Avoid asking questions that are easily answered by the job description or company website.

4. Dress Professionally and Arrive Punctually

Present yourself in a professional manner and arrive on time for the interview.

- Wear clean, business-appropriate attire that is comfortable and allows for movement.

- Plan your route and transportation in advance to avoid any delays.

5. Be Confident and Enthusiastic

Convey your confidence and enthusiasm during the interview.

- Maintain eye contact, speak clearly, and articulate your answers with conviction.

- Express your passion for the field and demonstrate your willingness to learn and contribute.

Next Step:

Now that you’re armed with the knowledge of Die Casting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Die Casting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini