Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Die Casting Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

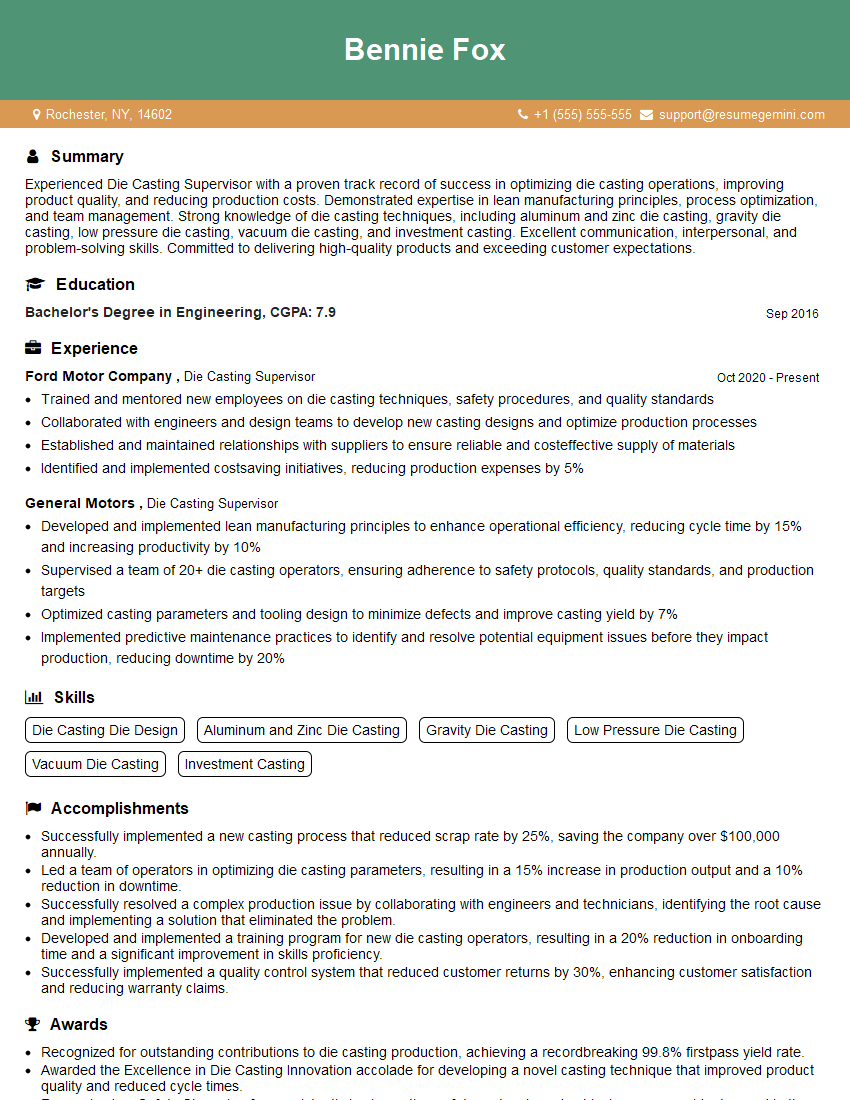

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Casting Supervisor

1. Define the various types of die casting processes and explain the advantages and disadvantages of each?

- High-pressure die casting: Uses high pressure to inject molten metal into the die cavity. Advantages include high production rates, good surface finish, and dimensional accuracy. Disadvantages include high tooling costs and limited part size.

- Low-pressure die casting: Uses low pressure to inject molten metal into the die cavity. Advantages include lower tooling costs, larger part size, and better mechanical properties. Disadvantages include slower production rates and lower surface finish.

- Gravity die casting: Uses gravity to fill the die cavity with molten metal. Advantages include low tooling costs and the ability to cast complex shapes. Disadvantages include lower production rates, poorer surface finish, and dimensional accuracy.

2. Describe the key parameters that influence the quality of die castings?

Material

- Melting point

- Fluidity

- Solidification rate

Process

- Injection pressure

- Injection speed

- Die temperature

- Cooling rate

Die Design

- Gate design

- Runner design

- Vent design

3. How do you ensure that die castings meet the required dimensional tolerances?

- Control the die temperature

- Maintain proper injection pressure and speed

- Use the correct die design

- Implement statistical process control (SPC)

- Inspect castings regularly

4. How do you troubleshoot common die casting defects?

- Porosity: Caused by entrapped air or gas. Can be reduced by optimizing the injection process, using a vacuum, or degassing the molten metal.

- Cold shut: Caused by the premature solidification of molten metal before it completely fills the die cavity. Can be reduced by increasing the injection pressure, speed, or die temperature.

- Flash: Caused by molten metal leaking out of the die cavity. Can be reduced by improving the die design, using a higher injection pressure, or increasing the die temperature.

- Shrinkage: Caused by the contraction of molten metal as it solidifies. Can be reduced by using a higher injection pressure, speed, or die temperature, or by adding alloying elements to the molten metal.

- Cracks: Caused by excessive stress or strain on the casting. Can be reduced by optimizing the die design, using a lower injection pressure or speed, or annealing the casting.

5. What are the safety precautions that need to be taken in a die casting operation?

- Wear appropriate personal protective equipment (PPE)

- Keep work areas clean and free of tripping hazards

- Operate equipment safely and follow established procedures

- Handle molten metal with care

- Be aware of potential hazards and take appropriate precautions

6. What is your experience with managing a team of die casting operators?

- Supervised a team of 10 die casting operators for 5 years

- Developed and implemented training programs to improve operator skills

- Monitored operator performance and provided feedback to improve efficiency

- Ensured that operators followed safety procedures

- Resolved operator issues and provided technical support

7. How would you implement a new die casting process in a manufacturing facility?

- Conduct a feasibility study to assess the viability of the new process

- Develop a detailed implementation plan

- Procure the necessary equipment and materials

- Train operators on the new process

- Implement the new process and monitor its performance

- Make necessary adjustments to the process to optimize its performance

8. What are the latest trends in die casting technology?

- Vacuum die casting: Uses a vacuum to remove air and gas from the die cavity, resulting in improved casting quality.

- Semi-solid metal casting: Uses a semi-solid metal feedstock, which reduces porosity and improves mechanical properties.

- 3D printing: Used to create complex die designs, which can reduce tooling costs and lead times.

- Artificial intelligence (AI): Used to optimize die casting processes and improve quality control.

- Automation: Used to increase productivity and reduce labor costs.

9. What is your understanding of the role of a Die Casting Supervisor?

- Supervise and coordinate the activities of die casting operators

- Ensure that die casting operations are performed safely and efficiently

- Maintain die casting equipment and ensure its proper operation

- Inspect die castings and ensure that they meet quality standards

- Troubleshoot and resolve die casting problems

- Provide technical support to die casting operators

- Train new die casting operators

10. Why are you interested in working as a Die Casting Supervisor at our company?

- I have over 10 years of experience in the die casting industry.

- I have a proven track record of success in supervising and managing die casting operations.

- I am familiar with the latest die casting technologies and trends.

- I am confident that I can contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Casting Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Casting Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Die Casting Supervisor is responsible for leading and supervising a team of employees in the production of die castings. They ensure that all castings meet quality standards and that production goals are met. The key responsibilities of a Die Casting Supervisor include:

1. Production Planning and Scheduling

The Die Casting Supervisor is responsible for planning and scheduling production to ensure that castings are produced on time and to the required quality.

- Develop and implement production schedules.

- Monitor production progress and make adjustments as necessary.

- Coordinate with other departments to ensure that all materials and resources are available.

2. Quality Control

The Die Casting Supervisor is responsible for ensuring that all castings meet the required quality standards.

- Inspect castings for defects.

- Identify and correct any problems that may affect the quality of the castings.

- Implement quality control procedures.

3. Safety and Maintenance

The Die Casting Supervisor is responsible for ensuring that all safety and maintenance procedures are followed.

- Train employees on safety procedures.

- Inspect equipment regularly and make sure it is in good working order.

- Perform maintenance on equipment as needed.

4. Team Leadership

The Die Casting Supervisor is responsible for leading and motivating a team of employees.

- Hire and train new employees.

- Set performance goals for employees.

- Provide feedback and coaching to employees.

Interview Tips

Preparing for an interview for a Die Casting Supervisor position requires research, practice, and confidence. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before the interview, take the time to learn about the company and the specific position you’re applying for. Visit the company’s website, read industry news, and connect with employees on LinkedIn. This will help you understand the company’s culture, goals, and the challenges and opportunities the position presents.

- Research the company’s history, products, and services.

- Read the job description carefully and identify the key skills and qualifications required.

- Look for news articles or press releases about the company to stay informed about its recent developments.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in Die Casting Supervisor interviews. By practicing your answers to these questions, you can ensure that you deliver clear, concise, and compelling responses.

- Tell me about yourself and your experience in die casting.

- What are your strengths and weaknesses as a supervisor?

- How do you ensure that castings meet quality standards?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions during the interview shows that you’re engaged, interested, and eager to learn more. Prepare a few questions that demonstrate your knowledge of the industry and your enthusiasm for the position.

- What are the biggest challenges facing the die casting industry today?

- What are the company’s plans for growth in the next few years?

- What opportunities are there for professional development and advancement within the company?

4. Dress Professionally and Arrive on Time

First impressions matter. Make sure you dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer and the company.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Be punctual and arrive at the interview location a few minutes early.

- Greet the interviewer with a firm handshake and make eye contact.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Die Casting Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.