Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Die Cutter Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

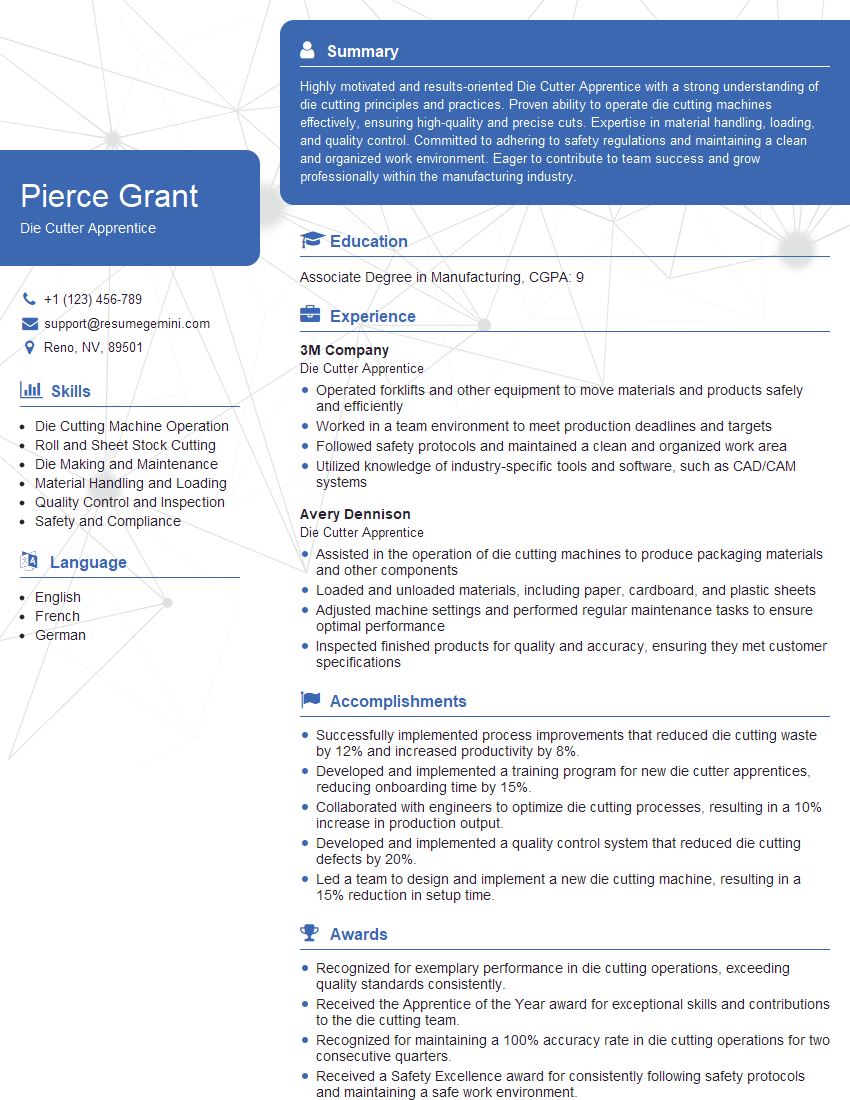

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Cutter Apprentice

1. Describe the process of die cutting in detail.

Die cutting is a process that uses a sharp metal die to cut shapes out of a material, typically paper, cardboard, or plastic. The die is typically mounted on a press, and the material is fed through the press. The die cuts the material to the desired shape, and the cut pieces are then ejected from the press.

- The first step in die cutting is to create a die. Dies are typically made of metal, and they are designed to cut a specific shape. The die is mounted on a press, and the material to be cut is fed through the press.

- The press applies pressure to the die, which cuts the material to the desired shape. The cut pieces are then ejected from the press.

- Die cutting can be used to create a variety of shapes, including circles, squares, rectangles, and ovals. Dies can also be used to cut more complex shapes, such as letters and logos.

- Die cutting is a versatile process that can be used to create a variety of products, including packaging, labels, and greeting cards.

2. What are the different types of die cutting machines?

Platen presses

- Platen presses are the most common type of die cutting machine. They use a flat platen to apply pressure to the die.

- Platen presses are relatively simple to operate, and they can be used to cut a variety of materials.

- However, platen presses can only apply a limited amount of pressure, so they are not suitable for cutting thick or tough materials.

Rotary presses

- Rotary presses use a rotating cylinder to apply pressure to the die.

- Rotary presses can apply more pressure than platen presses, so they can be used to cut thicker and tougher materials.

- Rotary presses are also faster than platen presses, so they are suitable for high-volume production.

Clicker presses

- Clicker presses are used to cut leather and other thick materials.

- Clicker presses use a sharp blade to cut the material, and they can apply a great deal of pressure.

- Clicker presses are typically used in the production of shoes, handbags, and other leather goods.

3. What are the safety precautions that must be taken when operating a die cutting machine?

- Always wear safety glasses when operating a die cutting machine.

- Never place your hands near the die cutting area.

- Keep the die cutting machine clean and free of debris.

- Never operate a die cutting machine that is not in good working order.

- Follow all manufacturer’s instructions for operating the die cutting machine.

4. What are the different types of dies that can be used in die cutting?

- Solid dies are made from a single piece of metal, and they cut a clean, sharp edge.

- Beveled dies have a beveled edge, which helps to prevent the material from tearing.

- Perforating dies have a series of small holes, which are used to create perforations in the material.

- Creasing dies have a blunt edge, which is used to create creases in the material.

- Embossing dies have a raised design, which is used to create raised images on the material.

5. What are the different materials that can be die cut?

- Paper

- Cardboard

- Plastic

- Leather

- Fabric

6. What are the different applications for die cutting?

- Packaging

- Labels

- Greeting cards

- Signs

- Displays

7. What are the challenges of die cutting?

- Die cutting can be a challenging process, especially when cutting complex or delicate materials.

- It is important to have the right equipment and dies for the job, and to follow the manufacturer’s instructions carefully.

- With practice, it is possible to become proficient in die cutting and produce high-quality results.

8. What is your experience with die cutting?

I have worked as a die cutter apprentice for the past two years. During that time, I have learned how to operate a variety of die cutting machines and dies. I have also gained experience in cutting a variety of materials, including paper, cardboard, plastic, and leather.

I am confident in my ability to produce high-quality die cut products. I am also a quick learner and I am eager to learn new things. I am confident that I would be a valuable asset to your team.

9. What are your career goals?

My career goal is to become a master die cutter. I would like to learn all aspects of die cutting, from design to production. I am also interested in learning about new die cutting technologies and techniques.

I believe that I have the skills and the drive to achieve my career goals. I am a hard worker and I am always willing to learn new things. I am also a team player and I am always willing to help out my colleagues.

10. What are your strengths and weaknesses?

Strengths

- I am a quick learner and I am eager to learn new things.

- I am a hard worker and I am always willing to go the extra mile.

- I am a team player and I am always willing to help out my colleagues.

Weaknesses

- I am sometimes too eager to get the job done, and I can make mistakes if I am not careful.

- I am not always the most patient person, and I can get frustrated if I am not able to get something done right away.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Cutter Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Cutter Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Die Cutter Apprentice is a hands-on professional who assists in the operation and maintenance of die-cutting machines.

1. Die Preparation and Setup

Assist in preparing and setting up dies on the die-cutting machine.

- Unload and load dies from the machine.

- Ensure proper alignment and registration of dies.

2. Machine Operation

Operate the die-cutting machine to cut materials according to specifications.

- Monitor machine operation and make adjustments as needed.

- Inspect cut materials for quality and accuracy.

3. Maintenance and Troubleshooting

Assist in maintaining and troubleshooting the die-cutting machine.

- Clean and lubricate machine parts.

- Diagnose and resolve operational issues.

4. Other Responsibilities

Perform other tasks as assigned by the supervisor.

- Assist in loading and unloading materials.

- Maintain a clean and organized work area.

Interview Tips

Preparing for an interview for a Die Cutter Apprentice position requires thorough preparation and a good understanding of the role and the industry.

1. Research the Company and Position

Research the company’s website and social media pages to gain insights into their culture, values, and recent projects.

- Review the job description carefully to identify the specific skills and experience required.

- Note down any specific technologies or machinery mentioned in the description.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience in operating and maintaining machinery, especially if it includes die-cutting equipment.

- Quantify your accomplishments and provide specific examples to demonstrate your skills.

- Highlight your ability to work in a team environment and follow instructions accurately.

3. Demonstrate Enthusiasm and Interest

Express your passion for the printing industry and your eagerness to learn about die-cutting.

- Share any previous experience or knowledge you have in the field.

- Show your commitment to safety and attention to detail.

4. Ask Informed Questions

Prepare thoughtful questions to ask during the interview that demonstrate your interest and engagement.

- Inquire about the company’s growth plans, recent projects, and industry trends.

- Ask about the apprenticeship program, its duration, and the opportunities for advancement.

5. Dress Professionally and Arrive on Time

Make a good impression by dressing appropriately and arriving on time for the interview.

- Wear clean and pressed business attire.

- Be punctual and respectful of the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Die Cutter Apprentice role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.