Are you gearing up for an interview for a Die Cutter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Die Cutter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

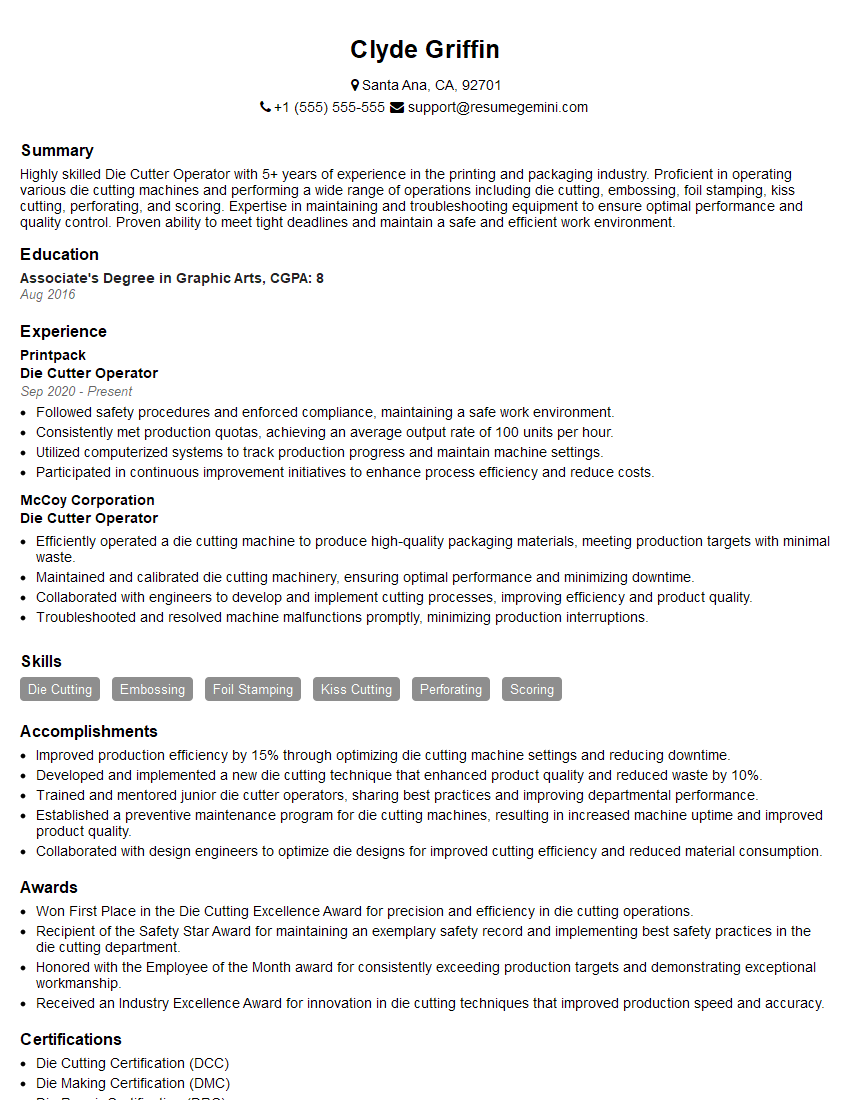

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Cutter Operator

1. What is the purpose of a die-cutting machine, and what are its key components?

- Die-cutting machines are used to cut out shapes or designs from various materials, such as paper, cardboard, plastic, and fabric.

- Key components include a die, a cutting surface, a feed system, and a press or cutting tool.

2. Describe the different types of dies used in die-cutting and their specific applications.

Steel Rule Dies

- Thin, flexible metal strips shaped to cut intricate designs.

- Used for cutting thin materials like paper and cardboard.

Rotary Dies

- Cylindrical dies with cutting edges engraved on their circumference.

- Suitable for high-speed, continuous cutting of materials like labels and packaging.

Flatbed Dies

- Thick, flat dies with sharp cutting edges.

- Used for cutting thick and rigid materials like plastic and metal.

3. How do you determine the appropriate die clearance for different materials and cutting applications?

- Die clearance refers to the gap between the cutting edge of the die and the surface being cut.

- Proper clearance depends on the material thickness, hardness, and desired cut quality.

- Too little clearance can result in tearing or crushing, while too much clearance can lead to ragged or imprecise cuts.

4. Discuss the importance of maintaining sharp cutting edges on dies and how you ensure their sharpness.

- Sharp cutting edges produce clean, precise cuts.

- Dull edges can cause material tearing, damage to the die, or reduced productivity.

- Regular sharpening and maintenance using specialized tools and techniques are crucial for maintaining sharpness.

5. Explain how you handle different types of material feeders, such as suction feeders and belt feeders.

Suction Feeders

- Use suction cups to pick and feed sheets one by one.

- Suitable for feeding delicate or slippery materials.

Belt Feeders

- Convey sheets using a continuous belt.

- Capable of handling larger and thicker materials at higher speeds.

6. What are the safety precautions you observe when operating a die-cutting machine?

- Wear appropriate safety gear, including eye protection, gloves, and protective clothing.

- Inspect the machine and dies before each use to ensure they are in good working order.

- Never touch the cutting area while the machine is running or dies are engaged.

- Follow established safety protocols and lockout procedures before performing any maintenance or repairs.

7. How do you troubleshoot common problems encountered in die-cutting operations, such as uneven cuts or material jams?

Uneven Cuts

- Check die clearance, cutting edge sharpness, and material thickness.

- Inspect the feed system for proper alignment and tension.

Material Jams

- Clear any obstructions or debris from the feeding and cutting areas.

- Adjust feeder settings, such as speed and air pressure, to optimize material flow.

8. Describe the quality control procedures you follow to ensure the accuracy and consistency of die-cut products.

- Regularly inspect dies and cutting surfaces for wear or damage.

- Use precision measuring tools to verify cut dimensions and tolerances.

- Implement statistical process control techniques to monitor and maintain product quality.

9. What maintenance tasks are essential for keeping a die-cutting machine in optimal condition?

- Lubricate moving parts as per the manufacturer’s recommendations.

- Clean and inspect dies regularly to remove debris and buildup.

- Perform preventive maintenance checks to identify and address potential issues.

10. How do you stay updated with advancements in die-cutting technology and best practices?

- Attend industry trade shows and conferences.

- Read trade publications and technical articles.

- Network with other die-cutting professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Cutter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Cutter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Cutter Operators are responsible for operating die cutting machines that cut and shape a variety of materials, such as paper, cardboard, plastic, and metal. They work in a variety of industries, including printing, packaging, and manufacturing.

1. Set up and operate die cutting machines

Die Cutter Operators must be able to set up and operate die cutting machines safely and efficiently. This includes adjusting the machine’s settings, loading the material to be cut, and starting and stopping the machine.

- Adjust the machine’s settings according to the job specifications.

- Load the material to be cut into the machine.

- Start and stop the machine.

2. Inspect the materials before and after cutting

Die Cutter Operators must inspect the materials before and after cutting to ensure that they meet the job specifications. This includes checking for defects, such as tears, holes, or wrinkles.

- Inspect the material for defects before cutting.

- Inspect the cut material for defects after cutting.

3. Maintain the die cutting machines

Die Cutter Operators must maintain the die cutting machines to ensure that they are operating safely and efficiently. This includes cleaning the machines, lubricating the moving parts, and making minor repairs.

- Clean the machines.

- Lubricate the moving parts.

- Make minor repairs.

4. Troubleshoot problems

Die Cutter Operators must be able to troubleshoot problems that occur with the die cutting machines. This includes identifying the problem, determining the cause of the problem, and taking steps to resolve the problem.

- Identify the problem.

- Determine the cause of the problem.

- Take steps to resolve the problem.

Interview Tips

Preparing for an interview can be nerve-wracking, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Die Cutter Operator position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, Glassdoor, and other online resources.

- Visit the company’s website.

- Read reviews on Glassdoor and other online resources.

- Talk to people in your network who work for the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Write down your answers to common interview questions.

- Practice your answers out loud.

- Get feedback from a friend or family member.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also avoid wearing strong perfumes or colognes.

- Wear clean, pressed clothes.

- Dress appropriately for a business setting.

- Avoid wearing strong perfumes or colognes.

4. Be on time

Punctuality is important for any interview, but it is especially important for an interview for a Die Cutter Operator position. This is because Die Cutter Operators are responsible for operating heavy machinery, and it is important to be on time for your shift so that you can start work on time.

- Plan your route to the interview in advance.

- Give yourself plenty of time to get to the interview.

- If you are running late, call the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Cutter Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!