Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Die Designer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Die Designer so you can tailor your answers to impress potential employers.

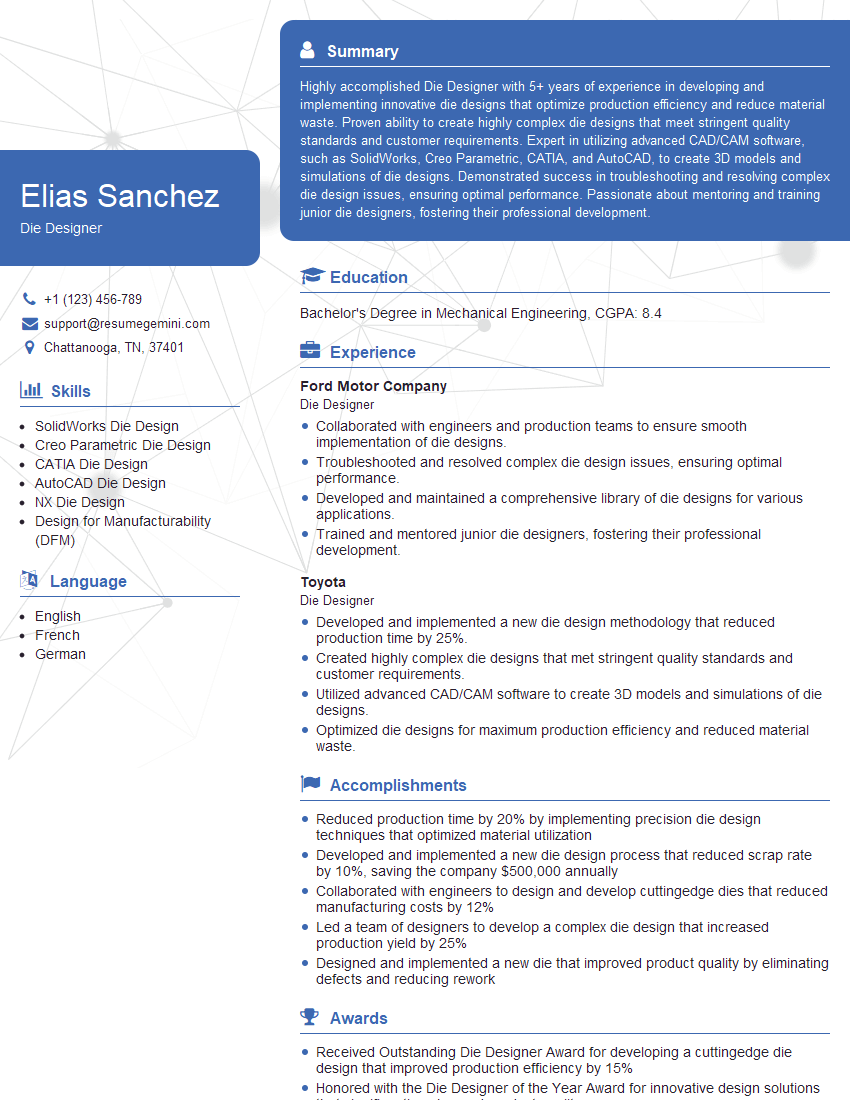

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Designer

1. Explain the process of designing a die for a sheet metal part.

- Initiate by understanding the part’s design intent and the desired material properties.

- Perform a thorough analysis of the part’s geometry, taking note of its complexity and any potential challenges.

- Determine the most suitable die design, considering factors such as the material’s thickness, the required tolerances, and the production volume.

- Utilize specialized software to create a 3D model of the die, ensuring accuracy and precision.

- Conduct simulations to evaluate the die’s performance, optimize its design, and prevent potential issues.

- Collaborate with other engineers and technicians to manufacture and test the die, ensuring it meets the required specifications.

2. How do you determine the appropriate blank size for a sheet metal part?

Material Properties:

- Consider the material’s thickness and its impact on the required blank size.

- Account for the material’s formability and its potential for stretching or shrinking.

Part Geometry:

- Analyze the part’s dimensions and shape, identifying any areas that may require additional material.

- Determine the necessary allowances for bending, flanging, and other forming operations.

Die Design:

- Review the die design and its clearance requirements to ensure sufficient material is available for proper forming.

- Consider the potential for material movement during the forming process.

3. Describe the factors that influence the selection of die materials.

- Type of forming operation (e.g., blanking, piercing, bending).

- Material properties of the workpiece (e.g., hardness, thickness).

- Production volume and expected die life.

- Cost and availability of different die materials.

- Heat treatment options and their impact on die performance.

4. How do you optimize the die design to minimize scrap?

- Utilize nesting techniques to efficiently arrange parts on the sheet metal.

- Consider the use of progressive dies to perform multiple operations in a single pass, reducing scrap.

- Employ scrap reduction features, such as skeleton layouts and skeletonized punches.

- Analyze the die design to identify areas where material can be saved without compromising part quality.

- Collaborate with suppliers to optimize material utilization and minimize waste.

5. Explain the principles of die clearance and its impact on part quality.

- Die clearance refers to the gap between the punch and die.

- Proper die clearance is crucial for achieving the desired part dimensions and preventing defects.

- Excessive clearance can lead to part distortion, burrs, and reduced accuracy.

- Insufficient clearance can cause the material to jam or tear, resulting in part damage.

- Die clearance is typically determined based on the material thickness, punch diameter, and material properties.

6. Describe the different types of die sets and their applications.

- Two-piece die set: Simple and cost-effective, used for low-volume production.

- Three-piece die set: Provides better alignment and support for higher volume production.

- Four-pillar die set: Offers maximum rigidity and precision, suitable for high-volume and complex parts.

- Progressive die set: Performs multiple operations in a single pass, increasing efficiency and reducing production time.

- Transfer die set: Used for large and complex parts, allowing for multiple stages of forming.

7. How do you ensure the accuracy and precision of a die design?

- Utilize precise measuring instruments and software for accurate part modeling.

- Conduct thorough simulations to verify the die’s performance and identify potential issues.

- Employ quality control measures during die manufacturing to ensure dimensional accuracy.

- Regularly calibrate and maintain measuring equipment to prevent errors.

- Collaborate with other engineers and technicians to review and validate the die design.

8. Describe the importance of die maintenance and its impact on die life.

- Regular maintenance prevents premature wear and tear, extending die life.

- Proper lubrication reduces friction and minimizes die wear.

- Periodic inspections allow for early detection of potential problems.

- Sharpening or replacing worn components ensures optimal die performance.

- Effective maintenance reduces downtime and production costs associated with die failures.

9. How do you troubleshoot common die problems, such as burrs or part distortion?

- Identify the root cause of the problem by analyzing the die design, material properties, and forming process.

- Adjust die clearance, punch and die profiles, or material properties to address burring issues.

- Modify the die design to improve part support and prevent distortion.

- Conduct simulations to evaluate potential solutions and optimize the die’s performance.

- Collaborate with other engineers and technicians to find effective troubleshooting strategies.

10. Explain the latest trends and advancements in die design technology.

- Computer-aided design (CAD) and computer-aided manufacturing (CAM) for precise die modeling and fabrication.

- Finite element analysis (FEA) for simulating and optimizing die performance.

- Additive manufacturing for producing complex die components with greater design freedom.

- Smart dies with sensors and control systems for real-time monitoring and adjustment.

- Use of advanced materials, such as high-strength steels and composites, to enhance die durability and longevity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Die Designer is an engineering professional who designs and develops dies used in manufacturing processes. They work closely with engineers, product designers, and manufacturers to create dies that meet specific requirements and produce high-quality products.

1. Design and Development

Die Designers are responsible for the design and development of dies. This involves creating 3D models of the die, as well as developing detailed drawings and specifications. They must also ensure that the die meets all applicable safety and quality standards.

- Create 3D models of dies using computer-aided design (CAD) software.

- Develop detailed drawings and specifications for dies.

- Ensure that dies meet all applicable safety and quality standards.

2. Prototyping and Testing

Once a die design has been completed, Die Designers typically create a prototype to test its functionality. They will then make any necessary adjustments to the design based on the results of the testing.

- Create prototypes of dies to test their functionality.

- Make any necessary adjustments to the design based on the results of the testing.

3. Manufacturing and Production

Die Designers work closely with manufacturers to ensure that dies are produced according to specifications. They may also be involved in the production process, troubleshooting any problems that arise.

- Work closely with manufacturers to ensure that dies are produced according to specifications.

- Troubleshoot any problems that arise during the production process.

4. Quality Control

Die Designers are responsible for ensuring that dies produce high-quality products. They will inspect dies and products regularly to ensure that they meet all applicable standards.

- Inspect dies and products regularly to ensure that they meet all applicable standards.

- Identify and correct any defects in dies or products.

Interview Tips

Preparing for a Die Designer interview can be challenging, but with the right strategies, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you better understand the role you would be playing within the company.

- Visit the company’s website and social media pages.

- Read articles and news about the company.

- Talk to people who work at the company, if possible.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Come up with a list of common interview questions.

- Practice answering these questions out loud.

- Get feedback from a friend or family member on your answers.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of an interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Come up with a list of questions to ask the interviewer.

- Make sure your questions are relevant to the position and the company.

- Be prepared to answer questions about your own questions.

4. Dress Professionally and Be On Time

First impressions matter, so it is important to dress professionally and be on time for your interview. This shows that you respect the company and the interviewer’s time.

- Choose clothing that is appropriate for a business setting.

- Arrive at the interview on time, or even a few minutes early.

- Be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Designer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!