Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Die Grinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Die Grinder so you can tailor your answers to impress potential employers.

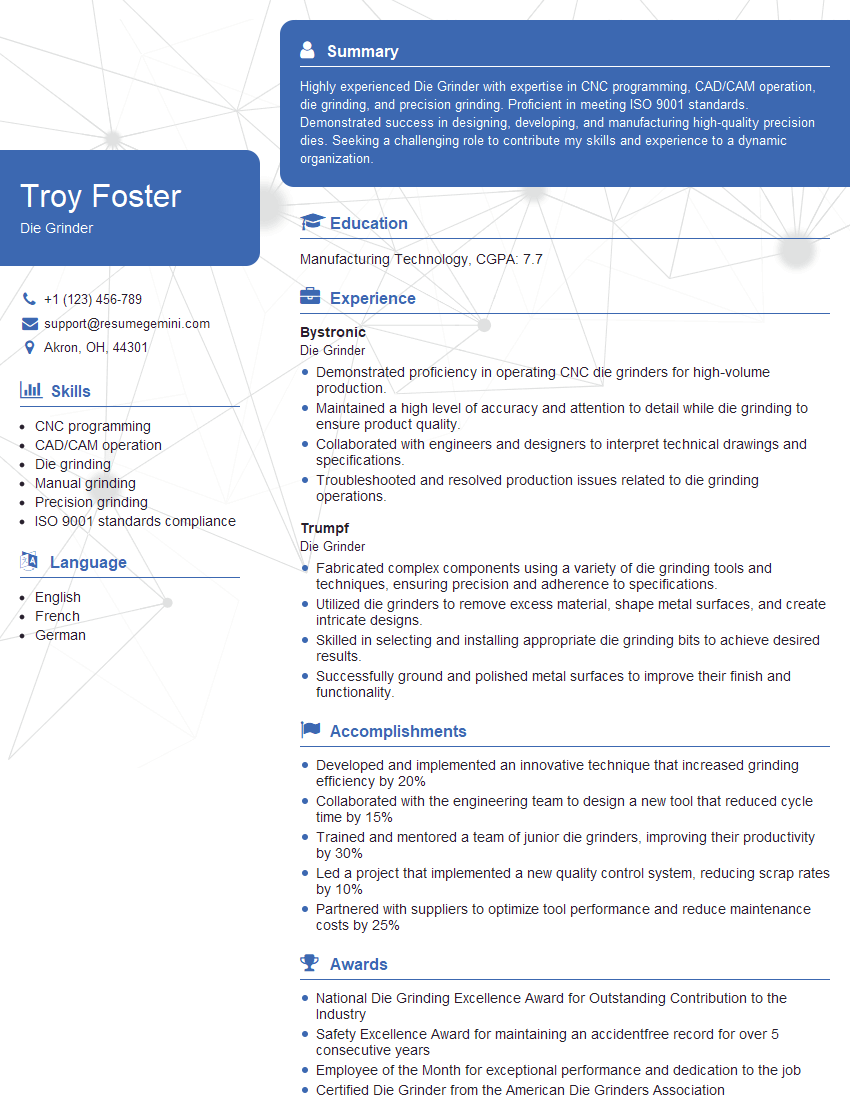

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Grinder

1. What are the different types of die grinders and their uses?

There are various types of die grinders, each designed for specific applications:

- Straight die grinders: Pencil-shaped grinders ideal for detailed work, such as cutting, grinding, and polishing in tight spaces.

- Angle die grinders: Feature a right-angle head for reaching difficult-to-access areas, used for grinding, deburring, and removing weld splatter.

- Long neck die grinders: Extended neck provides better reach and maneuverability, often used for grinding and polishing large surfaces.

- Air die grinders: Powered by compressed air, lightweight and portable, suitable for applications requiring high precision and control.

2. What are the safety precautions to consider when operating a die grinder?

To ensure a safe working environment, it is crucial to observe the following precautions:

- Wear appropriate protective gear: Eye protection (safety glasses or goggles), earplugs or ear muffs, and gloves.

- Inspect the grinder and accessories: Check for any damage or defects before use, including loose parts, cracked discs, or damaged cords.

- Use the correct grinding discs: Select the appropriate grit and size of grinding disc based on the material and application.

- Secure the workpiece: Ensure the workpiece is firmly secured to prevent movement during grinding.

- Maintain a safe grip: Hold the grinder firmly with both hands and keep a stable stance.

3. How do you determine the appropriate grinding speed and pressure for a specific application?

The optimal grinding speed and pressure depend on several factors:

- Material: Different materials require varying grinding speeds. For example, soft materials require lower speeds while hard materials need higher speeds.

- Grinding disc: The grit and hardness of the grinding disc influence the grinding pressure. A finer grit requires less pressure, while a coarser grit requires more.

- Application: The purpose of grinding (e.g., cutting, grinding, or polishing) determines the appropriate pressure.

- Experience: With practice, die grinders develop an intuitive understanding of the optimal settings for specific tasks.

4. What are the techniques for achieving precise cuts and finishes with a die grinder?

Achieving precise results requires a combination of techniques:

- Steady hand: Control the grinder with a steady and firm grip, avoiding shaking or sudden movements.

- Light pressure: Apply the appropriate grinding pressure to avoid gouging or over-grinding the material.

- Straight lines: Use a guide or template to ensure straight cuts. For curved cuts, use a steady and controlled motion.

- Multiple passes: For deeper cuts or delicate finishes, use multiple passes with lighter pressure rather than trying to remove too much material in one pass.

- Finishing techniques: Use finer grit discs or abrasive pads for smoothing and polishing the surface.

5. How do you maintain and troubleshoot die grinders?

Proper maintenance ensures the longevity and efficiency of die grinders:

- Regular cleaning: Remove dust and debris from the grinder using a brush or compressed air.

- Lubrication: Follow the manufacturer’s instructions for lubricating the moving parts, such as bearings and gears.

- Disc replacement: Worn or damaged grinding discs should be replaced immediately.

- Troubleshooting: If the grinder is not working properly, check for common issues such as loose connections, clogged air filters, or damaged components. Refer to the manufacturer’s manual for specific troubleshooting steps.

6. Describe the different abrasives used in die grinding and their applications.

The choice of abrasive depends on the material being ground and the desired finish:

- Aluminum oxide: General-purpose abrasive suitable for most metals, providing a fast cutting rate but rougher finish.

- Zirconia alumina: More durable and aggressive abrasive, ideal for grinding hard materials such as stainless steel and carbon steel, providing a finer finish.

- Silicon carbide: Suitable for grinding non-ferrous metals, ceramics, and glass, producing a very fine finish.

- Diamond: Most durable and expensive abrasive, used for grinding extremely hard materials such as concrete and stone.

7. How do you minimize dust and debris generation during die grinding?

To reduce dust and debris:

- Use a dust collector: Attach a dust collector to the grinder to capture airborne particles.

- Wet grinding: Use water or coolant as a lubricant to suppress dust and prolong disc life.

- Vacuum regularly: Clean the work area and grinder frequently using a vacuum cleaner.

- Wear a respirator: Use a NIOSH-approved respirator to protect against inhaling dust and debris.

8. What are the common challenges encountered in die grinding and how do you overcome them?

Common challenges and solutions in die grinding:

- Vibration: Use anti-vibration gloves or pads to reduce discomfort and maintain control.

- Disc breakage: Select the appropriate disc for the application and ensure it is securely attached.

- Overheating: Allow the grinder to cool down periodically and avoid excessive pressure.

- Difficulty reaching tight spaces: Use angle die grinders or long neck die grinders for improved accessibility.

- Material damage: Use the appropriate grinding speed and pressure, and practice proper techniques to avoid damaging the workpiece.

9. Describe a time when you successfully applied die grinding techniques to solve a specific problem or achieve a desired outcome.

Share a specific example where you used die grinding effectively:

- Project description: Briefly describe the project or task involving die grinding.

- Challenges: Outline any challenges or obstacles you encountered.

- Techniques used: Explain the specific die grinding techniques and abrasives used to overcome the challenges.

- Outcome: Highlight the successful resolution of the problem or achievement of the desired outcome.

10. What are your strengths and weaknesses as a die grinder?

Provide a balanced assessment of your abilities:

- Strengths: Highlight your skills, experience, and attributes that make you an effective die grinder.

- Development areas: Acknowledge areas where you can improve your skills or knowledge.

- Example: “My strengths lie in my precise cutting and finishing techniques, as well as my ability to operate a variety of die grinders. I am always looking to expand my knowledge and improve my skills, particularly in the area of advanced abrasive materials.”

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Grinders are responsible for operating power tools to shape, smooth, and polish various materials. Their primary duties involve:

1. Operating Die Grinding Equipment

Skilled in using a variety of die grinders, including pneumatic and electric models

- Selecting the appropriate grinding wheels, stones, and abrasives for specific materials and projects

- Adjusting and calibrating grinding equipment to achieve precise results

2. Shaping and Smoothing Materials

Expertly grinds, shapes, and smooths metal, plastic, wood, and other materials to meet specifications

- Removing burrs, sharp edges, and excess material from castings, forgings, and other components

- Polishing and finishing surfaces to achieve desired texture and appearance

3. Deburring and Finishing

Meticulously removes burrs, sharp edges, and imperfections from materials

- Ensuring that components meet quality standards and specifications

- Performing precision deburring and finishing operations on delicate or complex parts

4. Quality Control and Inspection

Maintains high standards of quality by inspecting finished products

- Identifying and correcting any defects or inconsistencies in the grinding process

- Adhering to established quality standards and procedures

Interview Tips

To excel in a Die Grinder interview, consider these preparation tips:

1. Research the Company and Industry

Demonstrate your interest in the company by researching their history, values, and industry standing

- Identify any specific projects or initiatives that align with your skills and interests

- Prepare questions that show you have thoroughly researched the company and industry

2. Highlight Your Technical Skills

Emphasize your proficiency in operating various types of die grinding equipment

- Quantify your experience in hours or projects completed

- Discuss your expertise in selecting and using appropriate grinding wheels and abrasives

3. Showcase Problem-Solving Abilities

Provide examples of how you have successfully resolved technical challenges related to die grinding

- Explain how you troubleshoot equipment issues and implement effective solutions

- Describe situations where you identified and corrected quality defects in finished products

4. Emphasize Safety and Quality

Stress your commitment to safety and maintaining high-quality standards

- Highlight your knowledge of safety protocols and regulations related to die grinding

- Explain how you ensure that your work meets or exceeds established quality specifications

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Die Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Die Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.