Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Die Hardener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

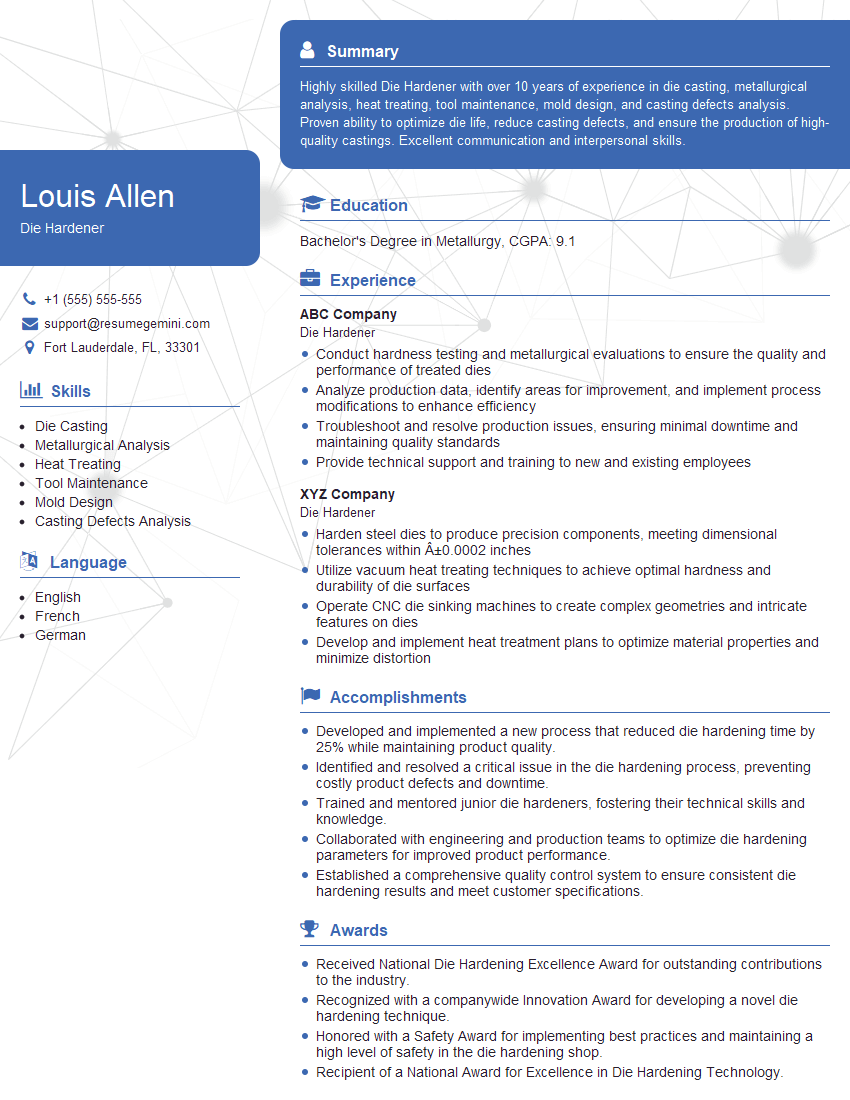

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Hardener

1. What are the different types of dies used in die hardening, and what are their respective applications?

- Cold dies are used to form metal at room temperature.

- Warm dies are used to form metal at elevated temperatures, typically between 150 and 300 degrees Celsius.

- Hot dies are used to form metal at high temperatures, typically above 500 degrees Celsius.

2. What are the different factors that affect the quality of the hardened die?

Material selection

- The type of steel used

- The heat treatment process

Design

- The geometry of the die

- The thickness of the die

Manufacturing process

- The precision of the machining

- The quality of the surface finish

3. What are the different types of die hardening processes, and what are their respective advantages and disadvantages?

- Induction hardening is a process that uses an electric current to heat the die.

- Flame hardening is a process that uses a flame to heat the die.

- Laser hardening is a process that uses a laser to heat the die.

4. What are the different factors that affect the hardness of the die?

- The temperature of the die

- The time that the die is heated

- The cooling rate of the die

5. What are the different types of testing methods used to evaluate the quality of the hardened die?

- Hardness testing

- Microstructure testing

- Fractography

6. What are the different types of defects that can occur in the die hardening process, and how can they be prevented?

- Cracking

- Warpage

- Soft spots

7. What are the different types of equipment used in the die hardening process?

- Induction hardening machines

- Flame hardening machines

- Laser hardening machines

- Hardness testing machines

- Microstructure testing machines

- Fractography machines

8. What are the different types of safety precautions that must be taken when working with the die hardening process?

- Wear appropriate safety gear

- Be aware of the hazards of the process

- Follow all safety procedures

9. What are the different types of industry standards that apply to the die hardening process?

- ASTM International

- SAE International

- ISO

10. What are the different types of career opportunities available in the field of die hardening?

- Die hardener

- Die hardening engineer

- Die hardening manager

- Die hardening researcher

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Hardener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Hardener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Die Hardener is responsible for the hardening and tempering of metal dies and tools used in various manufacturing processes. The primary objective is to enhance the durability, strength, and wear resistance of these components.

1. Die Hardening and Tempering:

Harden dies and tools using various techniques such as heat treatment, quenching, and tempering to achieve the desired hardness, strength, and toughness.

- Select appropriate hardening and tempering parameters based on the material and application requirements.

- Monitor and control temperature, heat, and cooling rates during the hardening and tempering processes to ensure optimal results.

2. Die Preparation:

Prepare dies and tools for hardening by cleaning, degreasing, and preheating them to prevent distortion and cracking during the hardening process.

- Inspect dies and tools for defects or damage before hardening to avoid any potential failures.

- Apply protective coatings or lubricants to prevent oxidation and decarburization during the hardening process.

3. Quality Control and Inspection:

Inspect hardened and tempered dies and tools to ensure they meet the required specifications for hardness, dimensions, and surface finish.

- Perform hardness testing using Rockwell or Vickers hardness testers to verify the achieved hardness.

- Inspect the dimensions and surface finish of dies and tools to ensure they conform to the design specifications.

4. Equipment Maintenance:

Maintain and calibrate equipment used in the hardening and tempering processes, including furnaces, quenching tanks, and tempering ovens.

- Monitor equipment performance and identify any potential issues to ensure smooth and efficient operations.

- Perform regular maintenance and calibration to ensure accurate temperature control and consistent results.

Interview Preparation Tips

Preparing for an interview for a Die Hardener position requires a combination of technical knowledge, research, and interview skills. Here are some tips to help you ace your interview:

1. Research the Company and Position:

Before the interview, thoroughly research the company and the specific Die Hardener position. Understand their business, values, and the role’s responsibilities and requirements.

- Visit the company’s website, LinkedIn page, and any other relevant sources to gather information.

- Read industry publications and articles to stay up-to-date on best practices and technological advancements in die hardening.

2. Practice Your Technical Skills:

Review your technical skills and knowledge related to die hardening and tempering processes, including heat treatment techniques, quenching methods, and tempering procedures.

- Refresh your understanding of different types of steels and their heat treatment characteristics.

- Practice explaining complex technical concepts in a clear and concise manner.

3. Highlight Your Experience and Skills:

During the interview, emphasize your relevant experience and skills that align with the job requirements. Use specific examples to demonstrate your capabilities.

- Quantify your accomplishments whenever possible, using numbers and metrics to showcase your impact.

- Be prepared to discuss your experience in troubleshooting and problem-solving related to die hardening and tempering.

4. Prepare Questions for the Interviewer:

Asking well-informed questions shows your engagement and interest in the position. Prepare thoughtful questions related to the company, the role, and the industry.

- Ask about the company’s current projects or challenges related to die hardening.

- Inquire about opportunities for professional development and training within the organization.

5. Dress Professionally and Arrive Punctually:

First impressions matter, so dress professionally and arrive punctually for the interview. Maintain a positive and confident demeanor throughout the process.

- Choose clothing that is appropriate for a professional setting, such as a suit or business casual attire.

- Plan your route and allow ample time to arrive at the interview location without any delays.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Die Hardener, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Die Hardener positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.